Super-critical water degraded polyester gradient phase change heat storage material and preparation method thereof

A phase change heat storage material and polyester degradation technology, applied in the field of phase change materials and their heat storage, can solve the problems of changing the phase change point, reducing the proportion of sensible heat, low efficiency, etc., to improve thermal conductivity, good Compatibility, effect of reducing insulation cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

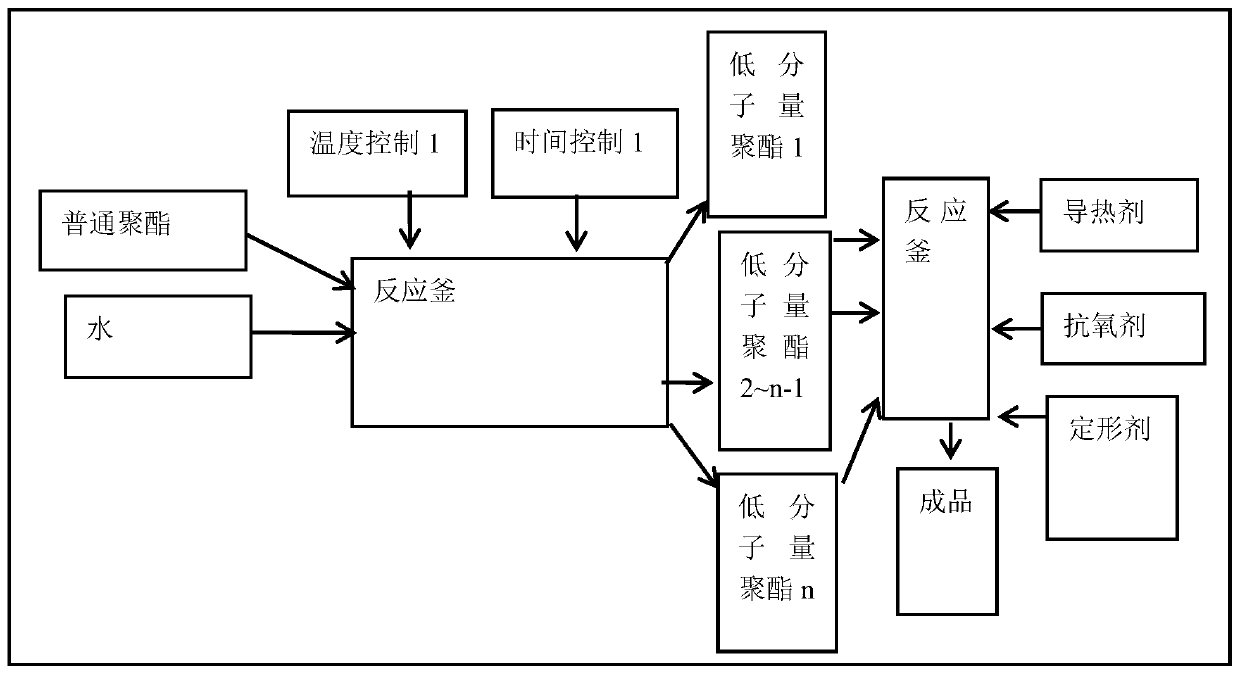

Method used

Image

Examples

Embodiment 1

[0038] Put 100kg of polyester into the reaction kettle, add 50kg of water to the reaction kettle, the temperature is 400°C, seal and heat for 30 minutes, remove water and dry to obtain a low molecular weight polyester with a molecular weight of 1200 and a melting point of 61°C.

[0039] Put 100kg of polyester into the reaction kettle, add 40kg of water to the reaction kettle, the temperature is 385°C, seal and heat for 20 minutes, remove water and dry to obtain a low molecular weight polyester with a molecular weight of 2500 and a melting point of 77°C.

[0040] Add 100kg of polylactic acid into the reactor, add 30kg of water to the reactor, set the temperature at 375°C, seal and heat for 10 minutes, remove the water and dry to obtain a low molecular weight polyester with a molecular weight of 5500 and a melting point of 86°C.

[0041] The low-molecular-weight polyesters with the above three melting points are used in equal proportions to form a gradient phase-change heat stora...

Embodiment 2

[0045] Put 100kg of polyester into the reaction kettle, add 50kg of water to the reaction kettle, the temperature is 400°C, seal and heat for 30 minutes, remove water and dry to obtain a low molecular weight polyester with a molecular weight of 1200 and a melting point of 61°C.

[0046] Put 100kg of polyester into the reaction kettle, add 40kg of water to the reaction kettle, the temperature is 385°C, seal and heat for 20 minutes, remove water and dry to obtain a low molecular weight polyester with a molecular weight of 2500 and a melting point of 77°C.

[0047] Add 100kg of polylactic acid into the reactor, add 30kg of water to the reactor, set the temperature at 375°C, seal and heat for 10 minutes, remove the water and dry to obtain a low molecular weight polyester with a molecular weight of 5500 and a melting point of 86°C.

[0048] The above three kinds of low-molecular-weight polyesters with melting points are used in equal proportions to form a gradient phase-change heat ...

Embodiment 3

[0052] Put 100kg of polyester into the reaction kettle, add 50kg of water to the reaction kettle, the temperature is 400°C, seal and heat for 30 minutes, remove water and dry to obtain a low molecular weight polyester with a molecular weight of 1200 and a melting point of 61°C.

[0053] Put 100kg of polyester into the reaction kettle, add 40kg of water to the reaction kettle, the temperature is 385°C, seal and heat for 20 minutes, remove water and dry to obtain a low molecular weight polyester with a molecular weight of 2500 and a melting point of 77°C.

[0054] Put 100kg of polyester into the reaction kettle, add 30kg of water to the reaction kettle, the temperature is 375°C, seal and heat for 10 minutes, remove water and dry to obtain a low molecular weight polyester with a molecular weight of 5500 and a melting point of 86°C.

[0055] The above three low molecular weight polyesters with melting points are composed of gradient phase change heat storage materials in a ratio of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com