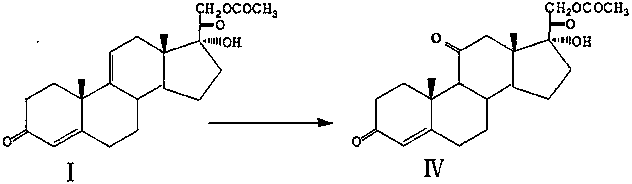

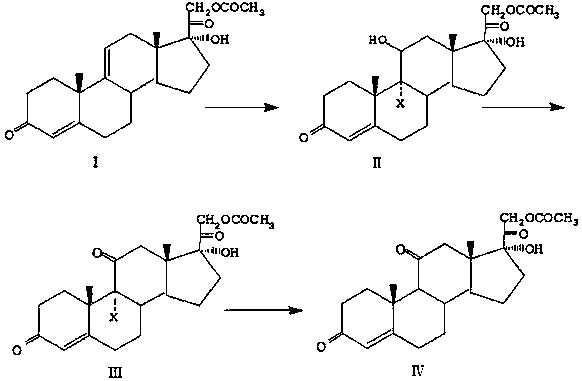

Method for preparing cortisone acetate in one pot

A technology of cortisone acetate and acid catalyst, applied in the direction of steroids, organic chemistry, etc., can solve the problems of complicated post-treatment, large amount of waste water, serious environmental pollution, etc., and achieve reduced production costs, reduced emissions, and obvious The effect of competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A. Under nitrogen protection, add 20ml of acetone, 80ml of chloroform, and 1ml of 70% perchloric acid into the reaction flask, cool down to -5-0°C, add 20g of anecortamate acetate, 10g of dibromohydantoin in sequence, and keep warm React for 5 hours, TLC (dichloromethane: acetone = 6:1) detects no spots at Rf 0.91, add 15ml of 20% sodium sulfite solution to quench the reaction;

[0021] B. Slowly add 20ml of Jones reagent to the reaction solution, keep the temperature at 0-5°C, and keep the temperature for about 1 hour. After the drop is completed, keep the reaction for 3 hours. ) Detect that there is no spot at Rf 0.75, add 30ml of 20% sodium sulfite solution to quench the reaction;

[0022] C. Add 20ml of drinking water to the system, stir for 5 minutes, let stand for 30 minutes, separate the organic layer, extract the water layer with 20ml of chloroform, combine the organic layers, add 10ml of glacial acetic acid to the organic layer, and control the temperature for ...

Embodiment 2

[0024] A. Under the protection of nitrogen, add 20ml of acetone, 80ml of chloroform, and 2ml of 40% fluoroboric acid into the reaction bottle, cool down to -5-0°C, add 20g of anecortamate acetate, 10g of dibromohydantoin in sequence, and keep warm for the reaction After 5 hours, TLC (dichloromethane: acetone = 6:1) detected no spots at Rf 0.91, and added 15ml of 20% sodium sulfite solution to quench the reaction;

[0025] B. Slowly add 20ml of Jones reagent to the reaction solution, keep the temperature at 0-5°C, and keep the temperature for about 1 hour. After the drop is completed, keep the reaction for 3 hours. ) Detect that there is no spot at Rf0.75, add 30ml of 20% sodium sulfite solution to quench the reaction;

[0026] C. Add 20ml of drinking water to the system, stir for 5 minutes, let stand for 30 minutes, separate the organic layer, extract the water layer with 20ml of chloroform, combine the organic layers, add 10ml of glacial acetic acid to the organic layer, and ...

Embodiment 3

[0028] A. Under the protection of nitrogen, add 20ml of acetone, 100ml of dichloromethane, and 1ml of 70% perchloric acid into the reaction bottle, cool down to -5-0°C, add 20g of anecortamate acetate, 10g of dibromohydantoin in sequence, and keep warm React for 5 hours, TLC (dichloromethane: acetone = 6:1) detects no spots at Rf0.91, add 15ml of 20% sodium sulfite solution to quench the reaction;

[0029] B. Slowly add 20ml of Jones reagent to the reaction solution, keep the temperature at 0-5°C, and keep the temperature for about 1 hour. After the drop is completed, keep the reaction for 3 hours. ) Detect that there is no spot at Rf0.75, add 30ml of 20% sodium sulfite solution to quench the reaction;

[0030] C. Add 20ml of drinking water to the system, stir for 5 minutes, let stand for 30 minutes, separate the organic layer, extract the water layer with 20ml of dichloromethane, combine the organic layers, add 10ml of glacial acetic acid to the organic layer, and control the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com