Method for estimating low-temperature mechanical properties of PBT propellant based on contact angle data and formula

A contact angle and propellant technology, applied in the field of solid propellants, can solve problems such as danger, long cycle, time required and high economic cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

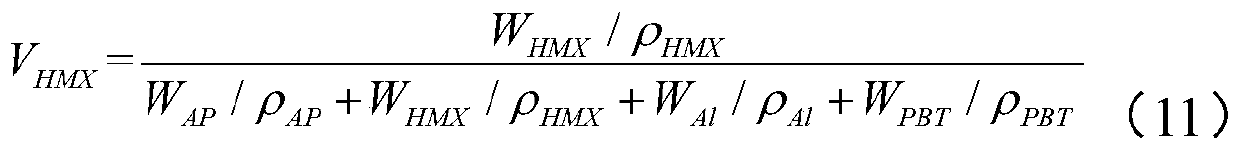

Method used

Image

Examples

Embodiment 1

[0057] (1) Contact angle test of PBT propellant filler and matrix

[0058] The SL200B contact angle measuring instrument was used to measure the contact angles of different reference solutions on the sample surface. The reference solution includes tricresyl phosphate, distilled water, glycerin, formamide, ethylene glycol, α-bromonaphthalene, etc. The samples include the main fillers (AP, HMX and Al) in the PBT propellant and the PBT matrix. The contact angles of different reference solutions on the main components of PBT propellants are shown in Table 1.

[0059] Table 1 The contact angles of different reference solutions on the main components of PBT propellants

[0060]

[0061] (2) Adhesion work of main filler-PBT matrix interface in PBT propellant

[0062] According to the contact angle test results of the PBT propellant filler and the matrix in Example (1), the surface tensions of AP, HMX, Al, and PBT matrix were calculated using formulas (3) to (7). The results are...

Embodiment 2

[0074] Embodiment 2 contact angle test method

[0075] Commonly used contact angle testing methods include Whilemy hanging method, dynamic capillary method, static drop method, etc. The contact angle method has the advantages of simple operation and accurate experimental results (the error of the two measurement results is not more than ±1).

[0076]The present invention adopts the static drop method to test the contact angle of the reference liquid on the surface of the propellant main component. The volume was set at 1 μL. After the titration liquid is in contact with the solid surface to be tested to form a lying drop, lift the liquid injection needle. After the contact angle of the liquid on the solid surface is stabilized, a microscopic image is obtained and the contact angle is measured. The arc tangent method was selected as the contact angle measurement method. The arc tangent method is the most direct angle measurement method.

[0077] The contact angles of diffe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com