Manufacturing method of knotless screen printing plate suitable for SE solar battery piece printing

A technology of solar cells and manufacturing methods, which is applied in the field of solar cells, can solve the problems that the distance between the thin grid lines cannot be guaranteed to be completely consistent, the congenital deficiency of no-network production cannot adapt to the SE process, and the black core of the cells, etc., so as to improve the photoelectric conversion efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

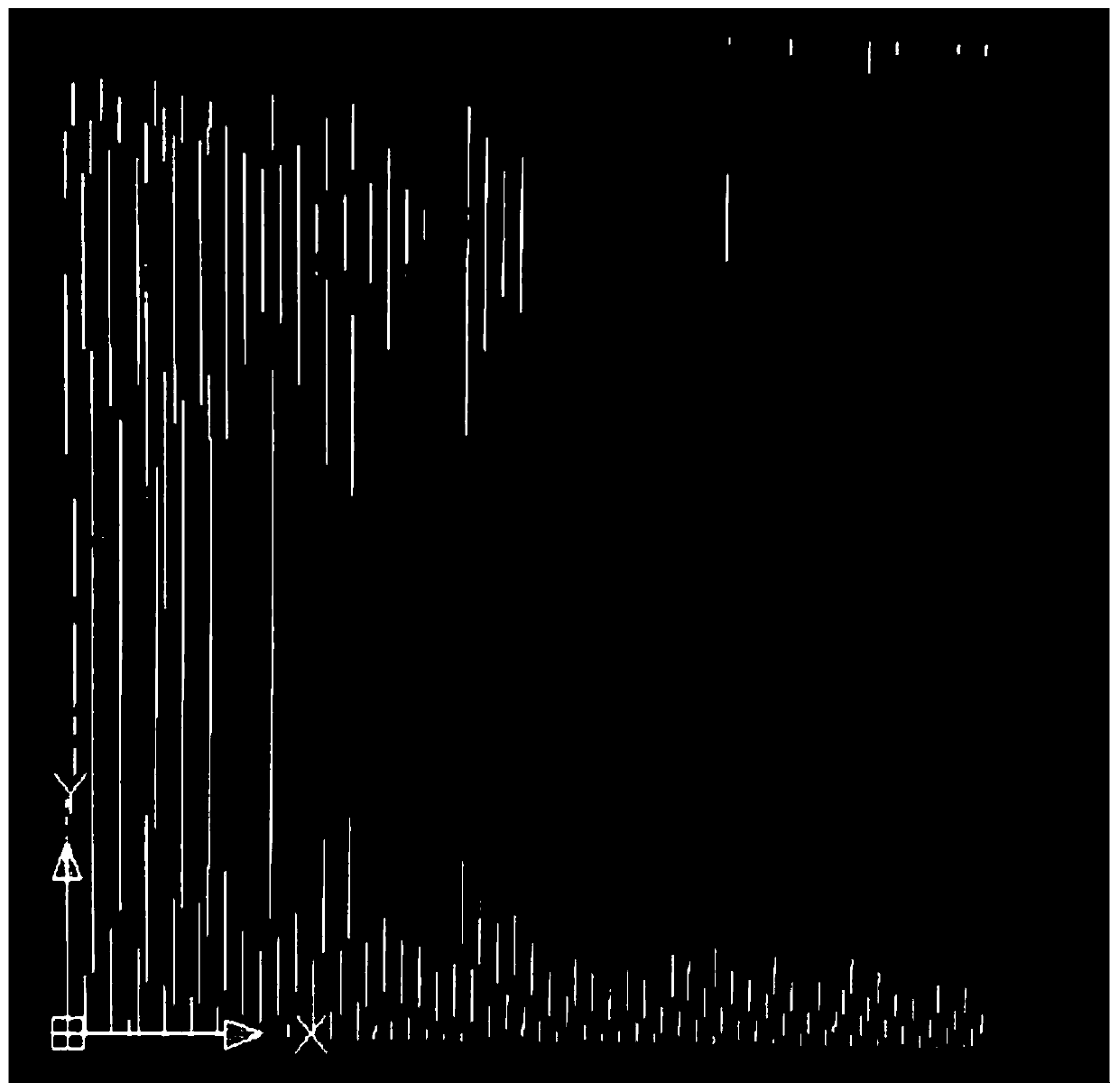

Image

Examples

Embodiment Construction

[0023] A method for making a knotless screen suitable for printing SE solar cells: After prefabricating a semi-finished knotless screen, the screen image on the screen is obtained by digitally comparing the image of the screen with the actual groove drawing. The production drawing for cutting corresponding to the overlapping part of the wire and the groove, and then the laser cutting equipment removes the mesh on the semi-finished knot-free screen according to the production drawing for cutting to obtain the corresponding knot-free screen.

[0024] The production process of the whole no-knot screen plate is as follows: Cleaning the screen frame - stretching the net - standing for 48H - marking the origin - scanning the mesh - processing the scanned CAD drawing - laser cutting overlapping mesh - drawing - out of the film - degreasing - Drying - Coating - Drying - Printing - Developing - Drying - Testing - Finished product.

[0025] Before scanning the mesh with the no-network s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com