Pd redispersed Pd/MCx supported catalyst and preparation method and application thereof

A supported catalyst and catalyst technology, applied in the direction of physical/chemical process catalysts, dehalogenation preparation, chemical instruments and methods, etc., can solve the problems of unenvironmental protection, unsatisfactory recovery of catalyst activity, low efficiency, etc., and achieve low production costs , excellent selectivity, simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

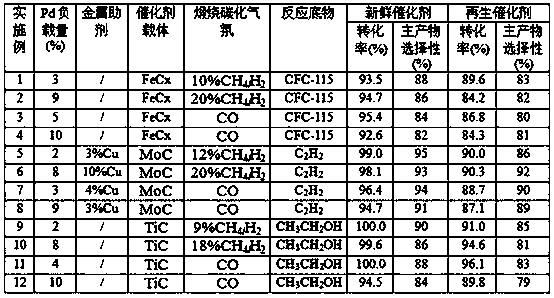

Examples

Embodiment 1

[0025] 1 g of fresh Pd / FeC with a Pd loading of 3% x The catalyst was loaded into a fixed-bed reactor, fed with hydrogen and reduced at 250°C for 2 hours. Then feed CFC-115 gas at a reaction temperature of 300°C and a space velocity of 720h -1 The reaction is carried out under the conditions, and the feed molar ratio of CFC-115 raw material to hydrogen is 1:1.5. After 80 hours of reaction, when the conversion rate of CFC-115 is lower than 65%, it is recorded as the sintering deactivation of the catalyst.

[0026] The catalyst deactivated by sintering in O with an oxygen volume content of 8% 2 / N 2 Pd / FeO was obtained by calcination at 450℃ for 0.5h x catalyst, and then 10% CH at 300°C 4 / H 2 Gas mixture (i.e. CH 4 / H 2 In the gas mixture, CH 4 The volume content is 10%) calcined and carbonized for 1h to recover Pd / FeC x The activity of the catalyst, that is, the regenerated catalyst is obtained. Under the same reaction conditions, the hydrodechlorination reaction of...

Embodiment 2

[0029] 1 g of fresh Pd / FeC with a Pd loading of 9% x The catalyst was loaded into a fixed-bed reactor, fed with hydrogen and reduced at 250°C for 2 hours. Then feed CFC-115 gas at a reaction temperature of 300°C and a space velocity of 720h -1 The reaction is carried out under the conditions, and the feed molar ratio of CFC-115 raw material to hydrogen is 1:1.5. After 80 hours of reaction, when the conversion rate of CFC-115 is lower than 65%, it is recorded as the sintering deactivation of the catalyst.

[0030] The catalyst deactivated by sintering in O with an oxygen volume content of 16% 2 / N 2atmosphere and calcination at 400°C for 8h to obtain Pd / FeO x catalyst, and then 20% CH at 650°C 4 / H 2 Restoration of Pd / FeC by Mixed Gas Calcination and Carbonization for 10h x The activity of the catalyst, that is, the regenerated catalyst is obtained. Under the same conditions, the hydrodechlorination reaction of CFC-115 under the action of the regenerated catalyst was ca...

Embodiment 3

[0033] 1 g of fresh Pd / FeC with a Pd loading of 5% x The catalyst was loaded into a fixed-bed reactor, fed with hydrogen and reduced at 250°C for 2 hours. Then feed CFC-115 gas at a reaction temperature of 300°C and a space velocity of 720h -1 The reaction is carried out under the conditions, and the feed molar ratio of CFC-115 raw material to hydrogen is 1:1.5. After 80 hours of reaction, when the conversion rate of CFC-115 is lower than 65%, it is recorded as the sintering deactivation of the catalyst.

[0034] The catalyst deactivated by sintering in O with an oxygen volume content of 6% 2 / N 2 atmosphere and calcination at 500°C for 1 h to obtain Pd / FeO x Catalyst, and then calcination and carbonization at 300 °C for 3 h to recover Pd / FeC x The activity of the catalyst, that is, the regenerated catalyst is obtained. Under the same conditions, the hydrodechlorination reaction of CFC-115 under the action of the regenerated catalyst was carried out again.

[0035] When...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com