Preparation method of low-overpotential cobalt-based composite electrolyzed water oxygen evolution catalyst

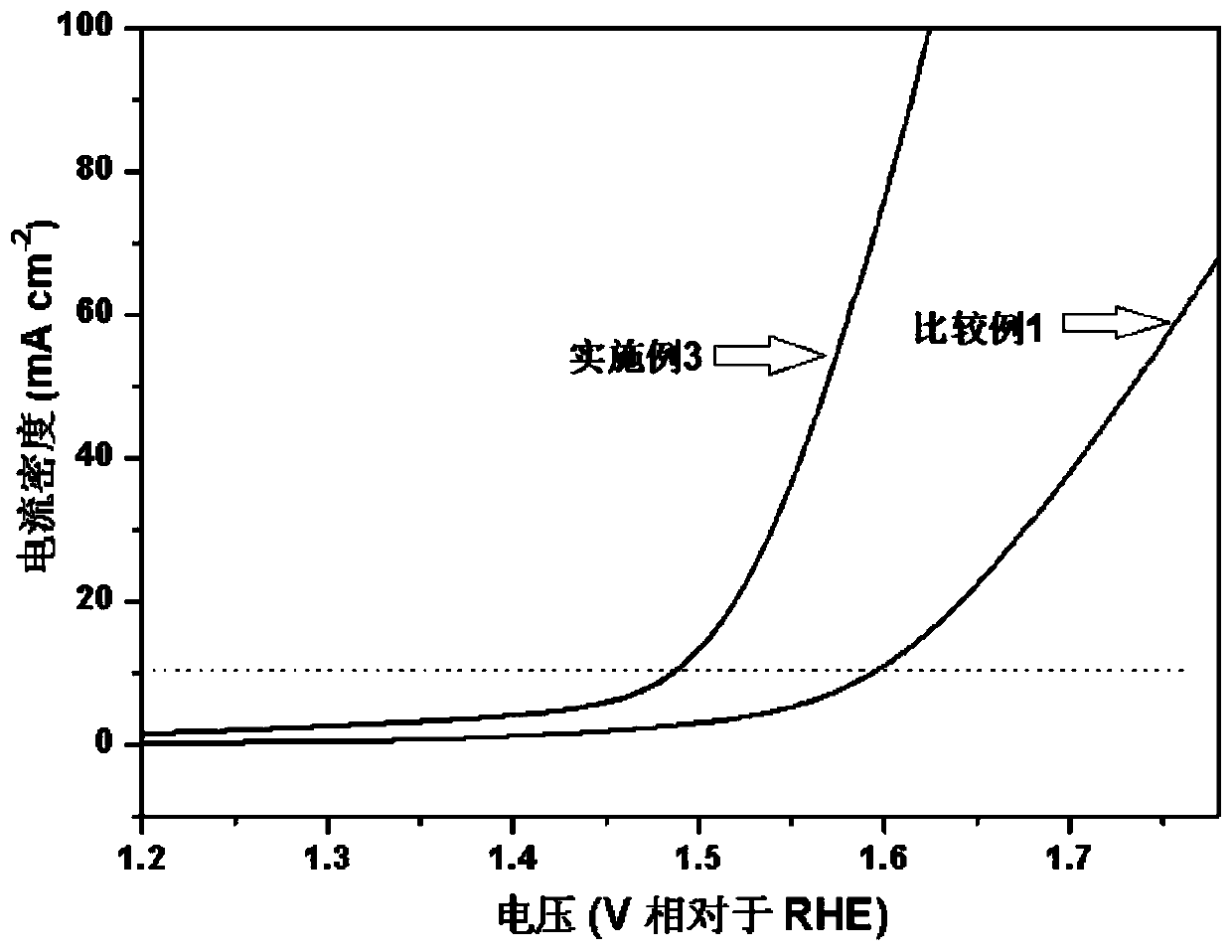

An overpotential and water electrolysis technology, which is applied in the field of electrolysis of water for oxygen evolution, can solve the problems of general performance, high energy consumption, and high overpotential of cobalt-based composite oxygen evolution catalyst, and achieves a wide range of materials, low energy consumption and improved catalytic performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention provides a preparation method of a low overpotential cobalt-based composite electrolytic water oxygen evolution catalyst, the steps are as follows:

[0030] (1) Fiber membrane I was prepared by electrospinning process;

[0031] (2) Preparation of precursor II by calcination;

[0032] (3) Calcination to obtain a low overpotential cobalt-based composite electrolytic water oxygen evolution catalyst.

[0033] Electrospinning can effectively control the morphology of cobalt-based MOF, combined with calcination process to prepare oxygen evolution catalyst, the method is simple, the preparation cost is low, and it is expected to obtain a cobalt-based oxygen evolution catalyst with low overpotential, low energy consumption and high performance. The field of electrolysis of water and energy has very important research significance and practical value.

[0034] In order to make the above objects, features and advantages of the present invention more comprehensible...

Embodiment 1

[0046] This implementation case shows a preparation method of a low overpotential cobalt-based composite electrolytic water oxygen evolution catalyst, including:

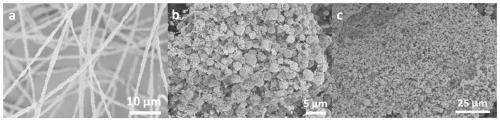

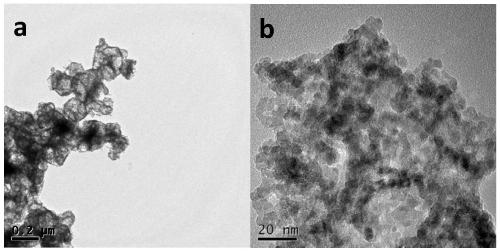

[0047] Add 0.1 g of polyacrylonitrile to 2.0 g of dimethylformamide solvent, add 0.1 g of ZIF-67 under magnetic stirring, and then stir at room temperature for 24 h. Cut a certain size of clean carbon paper as the base for electrospinning. Take a certain amount of uniformly mixed solution and ultrasonically vibrate for 30 minutes, and put it into a needle tube for electrospinning. Such as figure 2 a SEM image shows that ZIF-67 nanoparticles are uniformly distributed on the polyacrylonitrile fiber. The spun fiber membrane was put into a tube furnace, and calcined at 350°C and 500°C for 30 minutes in a nitrogen or argon atmosphere, respectively, with a heating rate of 5°C / min. Then it was placed in a muffle furnace and calcined at 300° C. for 1 h with a heating rate of 5° C. / min to obtain the target product. The ...

Embodiment 2

[0049] This implementation case shows a preparation method of a low overpotential cobalt-based composite electrolytic water oxygen evolution catalyst, including:

[0050] Add 0.1 g of polyacrylonitrile to 2.0 g of dimethylformamide solvent, add 0.2 g of ZIF-67 under magnetic stirring, and then stir at room temperature for 24 h. Cut a certain size of clean carbon paper as the base for electrospinning. Take a certain amount of uniformly mixed solution and ultrasonically vibrate for 30 minutes, and put it into a needle tube for electrospinning. Such as figure 2b SEM image, ZIF-67 nanoparticles aggregated into porous microspheres on polyacrylonitrile fibers. The spun fiber membrane was put into a tube furnace, and calcined at 350°C and 500°C for 30 minutes in a nitrogen or argon atmosphere, respectively, with a heating rate of 5°C / min. Then it was placed in a muffle furnace and calcined at 300° C. for 1 h with a heating rate of 5° C. / min to obtain the target product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com