A treatment method and treatment device for sulfur-containing flue gas

A treatment method and flue gas technology, applied in separation methods, sulfur preparation/purification, chemical instruments and methods, etc., can solve the problems of long treatment process, high treatment energy consumption, complicated treatment process, etc. High carbon fixation efficiency and good removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

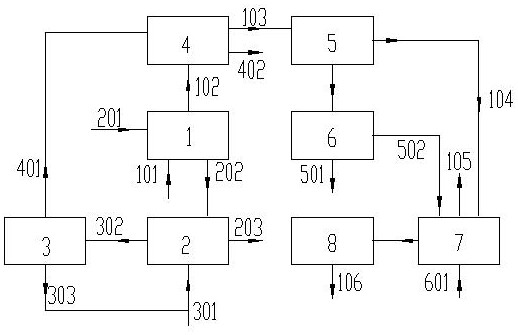

Method used

Image

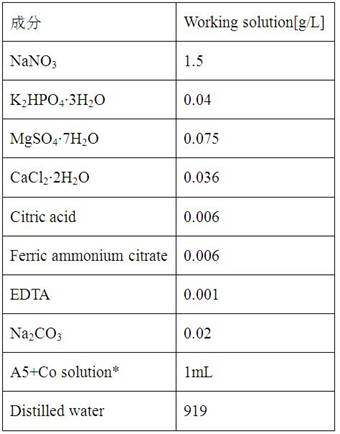

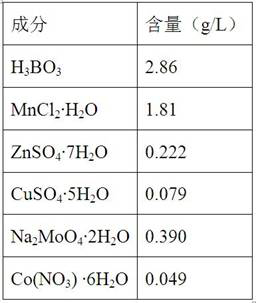

Examples

Embodiment 1

[0050] The waste alkali solution produced by a corporate ethylene device, wherein the COD is 58000 mg / L, the sodium sulfide concentration is 2.9 wt% (S 2- : 12200 mg / L), the sodium carbonate concentration was 2.0 wt% (20500 mg / L), and the sodium hydroxide concentration was 1.6 wt%.

[0051] The main composition of the flue gas generated by a company is: CO 2 The content is 14V%, the NOx content is 0.06V% (90% of NO), SO 2 The content is 0.04 V%.

[0052] The flue gas is introduced into the desulfurization absorption tower, and the vinyl scrapper liquid is used as the absorbent, and the pH of the absorbent liquid is 5-6, and the portion of the desulfurization absorption liquid is absorbed outside the absorbent liquid. Start replenishing the waste alkali solution, when the pH reaches 6, stopping the completion to obtain desulfurized smoke. The draft desulfurization absorbing solution is mainly based on sodium sulfite, adding cooked lime to make the desulfurization waste liquid...

Embodiment 2

[0057] The waste alkali produced by a corporate ethylene device, wherein the COD is 33000 mg / L, the sodium sulfide concentration is 2.1% by weight (S 2- : 8831 mg / L), the sodium carbonate concentration was 1.1 wt% (11275 mg / L), and the sodium hydroxide concentration was 1.2% by weight.

[0058] The main composition of the flue gas generated by a company is: CO 2 The content is 10 V%, the NOx content is 0.04V%, so 2 The content is 0.03 V%.

[0059] The flue gas is introduced into the desulfurization absorption tower, and the vinyl discardium liquid is used as the absorbent, and the pH of the absorbent liquid is 5.5-6.5, and the pH is less than 5.5, and some desulfurization absorption liquid is outside. Start replenishing the ethylene waste alkali solution, when the pH reaches 6.5, stopping the completion to obtain desulfurization. The draft desulfurization absorbing solution is mainly based on sodium sulfite, adding cooked lime to make the desulfurization waste liquid to rege...

Embodiment 3

[0064] A certain enterprise propane dehydrogenated olefin produced by the waste alkali solution, wherein sodium sodium sulfide is 6.83 wt%, sodium hydrosulfide is 4.8% by weight, COD is 117300 mg / L, pH of 13.5.

[0065] The main composition of the flue gas generated by a company is: CO 2 The content is 20 V%, the NOx content is 0.05V%, so 2 The content was 0.02 V%.

[0066] The flue gas is introduced into the desulfurization absorption tower, and the propylene waste base liquid is used as the absorbent, and the pH of the absorbent liquid is 5-6, when the pH is lower than 5, the portion of the desulfurization absorption liquid is outside. Start replenishing the propylene waste alkali solution, when the pH reaches 6, stopping the completion, resulting in desulfurization. The draft desulfurization absorbing solution is mainly based on sodium sulfite, adding cooked lime to make the desulfurization waste liquid to regenerate, to obtain CASO 3 Presets, calcined by high temperature, ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com