Healthy chocolates in which cocoa powder is replaced with pulp and preparing method of chocolates

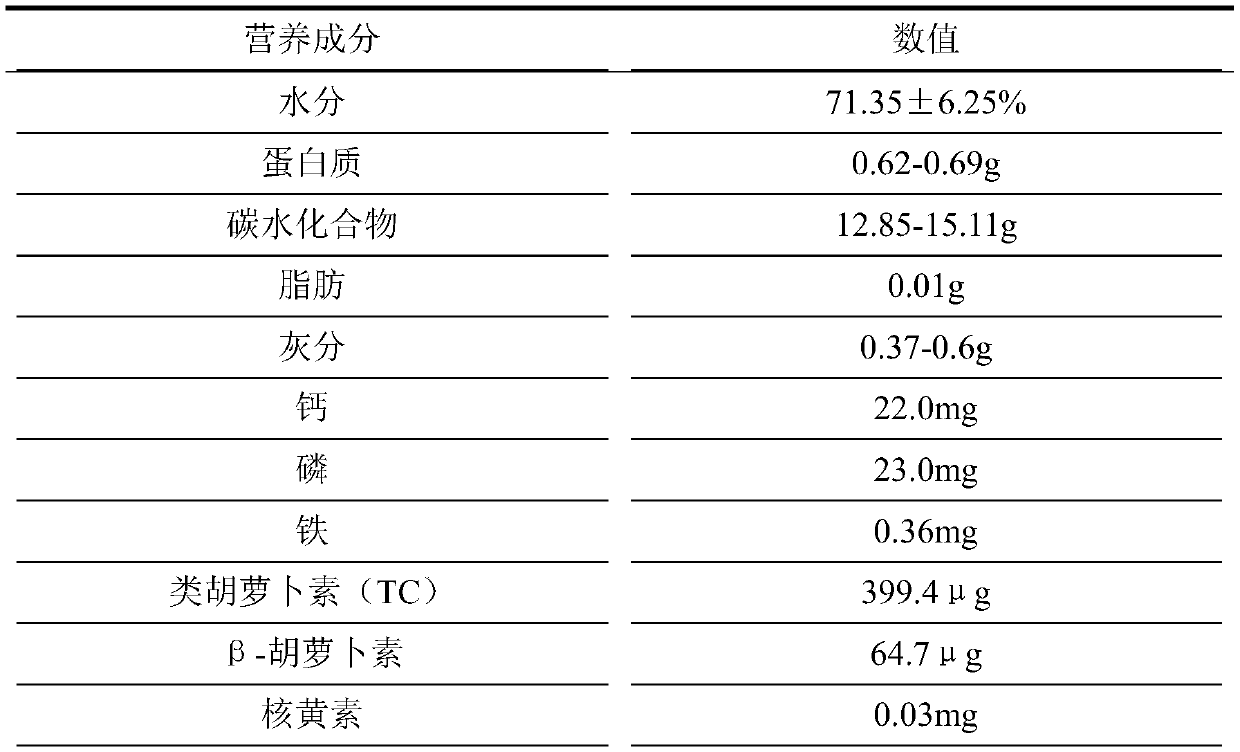

A chocolate and fruit pulp technology, applied in the field of food processing, can solve the problems of lack of nutritional value, high fat and sugar, complex chocolate production process, etc., and achieve the effects of rich nutrition and health, silky taste, and rich cocoa flavor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of the pulp substitute cocoa healthy chocolate of the present invention is:

[0030] Mix the black-fleshed persimmon powder and other ingredients evenly, heat and dissolve in a water bath at 40-45°C to form a chocolate slurry, homogenize at a speed of 2500-3000r for 5-15min, pasteurize at 60-95°C for 5s-30min, and pour into the mold after sterilization Molding hardening, demoulding.

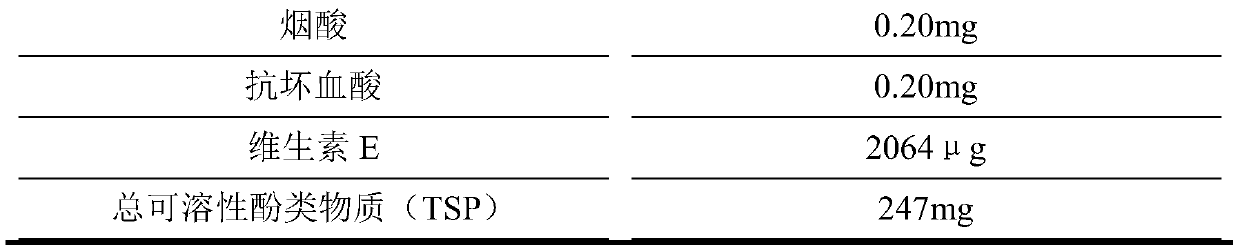

[0031] The pulp substitute cocoa healthy chocolate of the present invention preferably has the following mass percentages of components: 35-70% of black-fleshed persimmon powder, 0.5-5% of cocoa powder, 0.4-0.6% of lecithin, 18-30% of cocoa butter and sweetener 0-35%.

[0032] In another preferred embodiment of the present invention, the mass percentages of each component are: 10-44% of black-fleshed persimmon powder, 0.5-5% of cocoa powder, 0.4-0.6% of lecithin, 0.1-7.5% of cocoa butter, and 0.75-5% of light cream. 50%, sweetener 0-35%.

[0033] Further preferabl...

example 1

[0038] Wash, peel and remove the seeds of the black-fleshed persimmon fruit, stir and homogenize at 2500r for 10 minutes, add its maltodextrin, stir well and then dry and dehydrate at different temperatures. The first stage temperature is 55°C, time 10h The temperature is 45°C, the time is 24h, the third stage is placed in a ventilated and dry place, and the room temperature is re-moisturized for 2 days; the fourth stage is continued to use a drying box, 45°C, 24h, stirring continuously during the drying process, and then pulverized with a superfine pulverizer The particle size is 15 μm, and the black meat persimmon powder is obtained, and the water content is 5%.

preparation example 2

[0040]Wash, peel and remove the seeds of the black-fleshed persimmon fruit, stir and homogenize at 2800r for 13 minutes, add its maltodextrin, stir evenly, and then dry and dehydrate at different temperatures. The first stage is at 50°C for 14 hours. The temperature is 45°C, the time is 24h, the third stage is placed in a ventilated and dry place, and the room temperature is re-moisturized for 2 days; the fourth stage is continued to use a drying box, 45°C, 36h, stirring continuously during the drying process, and then pulverized with a superfine pulverizer The particle size is 18 μm, and the black-flesh persimmon powder is obtained, and the water content is 4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com