An electromagnetic heating device for alloy phase change material smoke heat source

An electromagnetic heating device and alloy phase technology, applied in induction heating, coil devices, etc., can solve the problems of specific heat absorption, large latent heat of phase change, large heat loss of resistance, hidden danger of heat dissipation of the device, etc., to achieve high latent heat of phase change, heating High Efficiency, Reduced Power Loss and Heat Loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

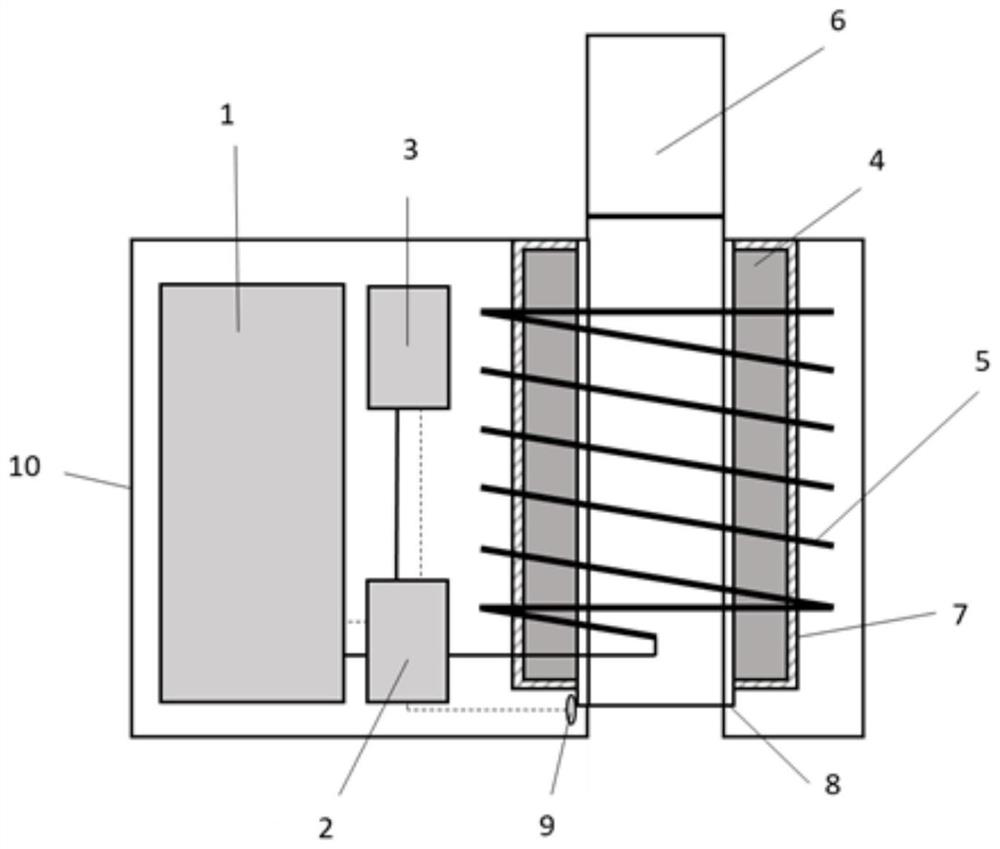

[0038] like figure 1 As shown, the present invention is an electromagnetic heating device for alloy phase change material cigarette heat source, including a battery power supply 1, a control chip 2, an indicator light and a vibrator 3, a phase change heating core 4, an electromagnetic induction coil 5, and a heating chamber 7. Metal heat transfer wall 8, thermocouple 9 and device shell 10.

[0039] Inside the shell 10 of the electromagnetic heating device, a battery power supply 1, a control chip 2, an indicator, a vibrator 3, and a thermocouple 9 are sequentially arranged from left to right, and are connected through a power supply circuit and a control circuit. The thermocouple 9 is arranged on the downward extension of the metal heat transfer wall 8. The metal heat transfer wall 8 is a circular cylinder surrounding the heating section of the pod 6, and the phase change heating core 4, the heating chamber 7 and the electromagnetic induction coil are in sequence outward. 5. ...

Embodiment 2

[0051] The implementation mode of this embodiment is identical with the implementation mode of embodiment 1, just:

[0052] The phase change heating core 4 is filled with 7g of Sn-9Zn alloy;

[0053] The electromagnetic induction coil 5 is an electromagnetic induction coil with a twist distance of 3mm, a length of 50mm, a diameter of 25mm, an operating voltage of 12v, and an operating current of 5A;

[0054] The matching pod 6 is a pod with a diameter of 5mm and a length of 35mm;

[0055] The heating chamber 7 is a ceramic tube with an inner diameter of 9.8mm, a length of 40mm, and a wall thickness of 1mm;

[0056] The metal heating wall 8 is a brass tube with an inner diameter of 5mm, a length of 40mm, and a wall thickness of 1mm;

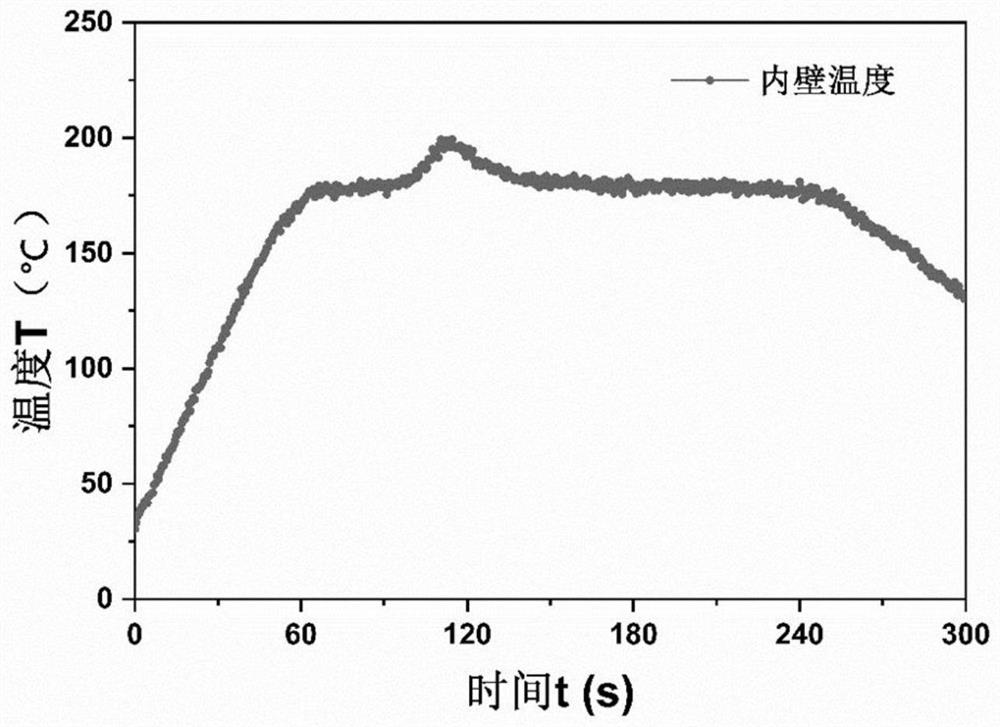

[0057] The heating power of the electromagnetic heating device for cigarettes in this embodiment is 60W, and the temperature it reaches during heating is 210°C, and the temperature is almost constant at about 185°C.

[0058] According to the me...

Embodiment 3

[0060] The implementation mode of this embodiment is identical with the implementation mode of embodiment 1, just:

[0061] The phase change heating core 4 is filled with 8g of Zn metal;

[0062] The electromagnetic induction coil 5 is an electromagnetic induction coil with a twist distance of 1.2mm, a length of 20mm, a diameter of 25mm, an operating voltage of 12v, and an operating current of 10A;

[0063] The matching pod 6 is a pod with a diameter of 8mm and a length of 20mm;

[0064] The heating chamber 7 is a ceramic tube with an inner diameter of 10mm, a length of 20mm, and a wall thickness of 1mm;

[0065] The metal heating wall 8 is a copper tube with an inner diameter of 8mm, a length of 20mm, and a wall thickness of 1mm;

[0066] The heating power of the electromagnetic heating device for cigarettes in this embodiment is 120W, and the temperature it reaches during heating is 425°C, and the temperature is relatively constant at about 418°C.

[0067] According to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com