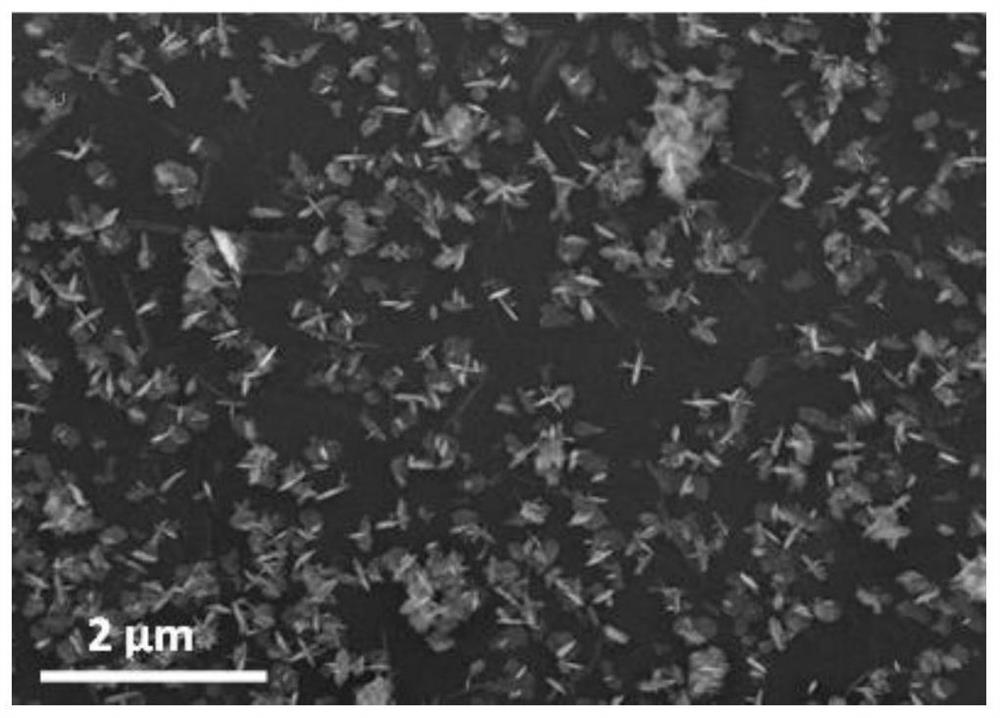

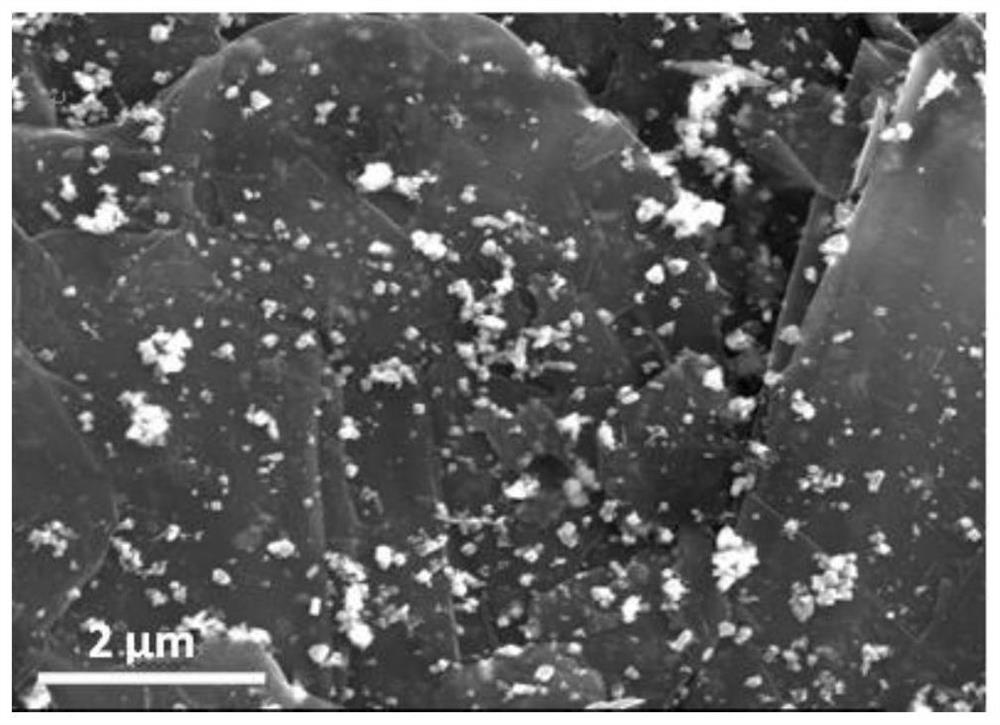

Expanded graphite negative electrode material loaded with cross needle-shaped tin oxide and preparation method thereof

A technology of expanded graphite and negative electrode materials, applied in the field of material preparation and expanded graphite negative electrode materials, can solve the problems of poor charge-discharge cycle performance and insufficient energy density, and achieve good charge-discharge cycle performance, good conductivity, and strong adsorption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

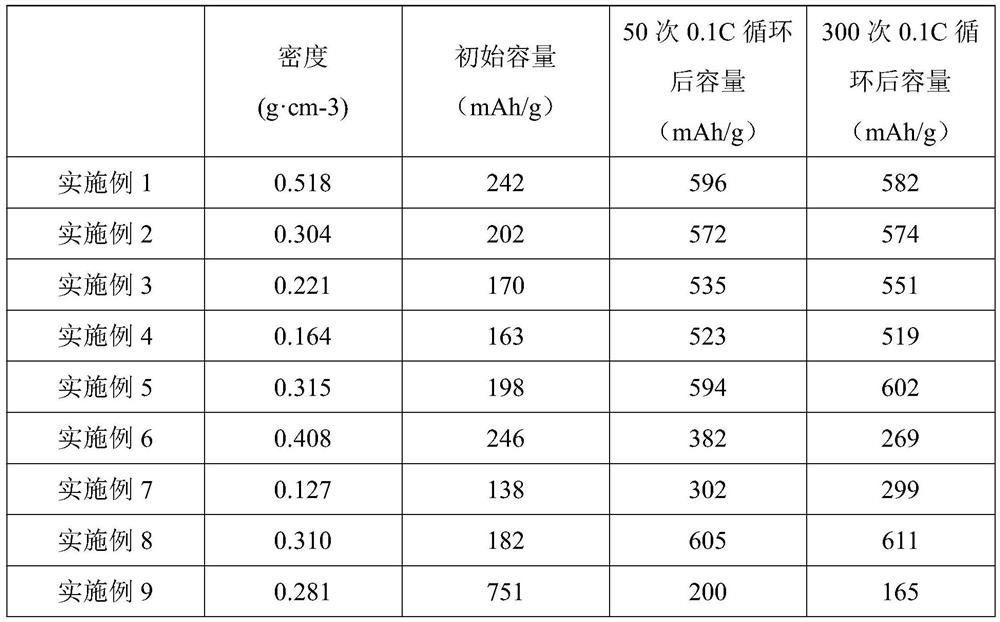

Embodiment 1

[0034] S1: Immerse the expanded graphite in water and stir for 10 minutes to obtain a 5g / L expanded graphite suspension;

[0035] S2: prepare 0.1mol / L tin-containing salt solution, then add structure-directing agent polyvinyl dimethyl ammonium chloride to the tin-containing salt solution, and dissolve; the added amount of the structure-directing agent is related to the mass of tin The ratio is 5:1;

[0036] S3: Slowly add 66.4 mL of the tin-containing salt solution containing the structure directing agent dropwise into 1 L of the expanded graphite suspension, and the dropwise addition is completed within 1 min;

[0037] S4: Heating the expanded graphite suspension treated in S3 to reflux for 0.5h, and cooling to room temperature;

[0038] S5: 62.7mg of sodium borohydride and 531.2mg of sodium hydroxide were dissolved in 10mL of water, then added dropwise to the suspension treated in S4, and stirred for 2 hours to obtain a composite material containing tin oxide and expanded g...

Embodiment 2

[0042] S1: Immerse the expanded graphite in water and stir for 30 minutes to obtain a 10g / L expanded graphite suspension;

[0043] S2: Prepare 0.3mol / L tin-containing salt solution, then add structure-directing agent polyvinyl dimethyl ammonium chloride to the tin-containing salt solution, and dissolve; the added amount of the structure-directing agent is related to the mass of tin The ratio is 10:1;

[0044] S3: Slowly add 22.1mL of the tin-containing salt solution containing the structure directing agent dropwise into 1L of the expanded graphite suspension, and the dropwise addition is completed within 1min;

[0045] S4: Heating the expanded graphite suspension treated in S3 to reflux for 1 h, and cooling to room temperature;

[0046] S5: 75.3 mg of sodium borohydride and 796.8 mg of sodium hydroxide were dissolved in 10 mL of water, and then added dropwise to the suspension treated in S4, and stirred for 3 hours to prepare a composite material containing tin oxide and expa...

Embodiment 3

[0050] S1: Immerse expanded graphite in water and stir for 1 hour to obtain a 15g / L expanded graphite suspension;

[0051] S2: Prepare 0.5mol / L tin-containing salt solution, then add structure-directing agent polyvinyl dimethyl ammonium chloride to the tin-containing salt solution, and dissolve; the added amount of the structure-directing agent is related to the quality of tin The ratio is 15:1;

[0052] S3: Slowly add 13.3mL of the tin-containing salt solution containing the structure directing agent dropwise into 1L of the expanded graphite suspension, and the dropwise addition is completed within 30s;

[0053] S4: Heating the expanded graphite suspension treated in S3 to reflux for 1.5h, and cooling to room temperature;

[0054] S5: 75.3mg of sodium borohydride and 1062.4mg of sodium hydroxide were dissolved in 10mL of water, then added dropwise to the suspension treated in S4, and stirred for 4 hours to prepare a composite material containing tin oxide and expanded graphi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com