A fuel staged gasification and low no x combustion boiler

A fuel classification and boiler technology, which is applied in the field of fuel classification gasification and low NOX combustion boilers, can solve the problems of insufficient reduction of flue gas content and increase of emission, and achieve better ignition stability, increase of oxygen content, and prevention of The effect of slagging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the drawings.

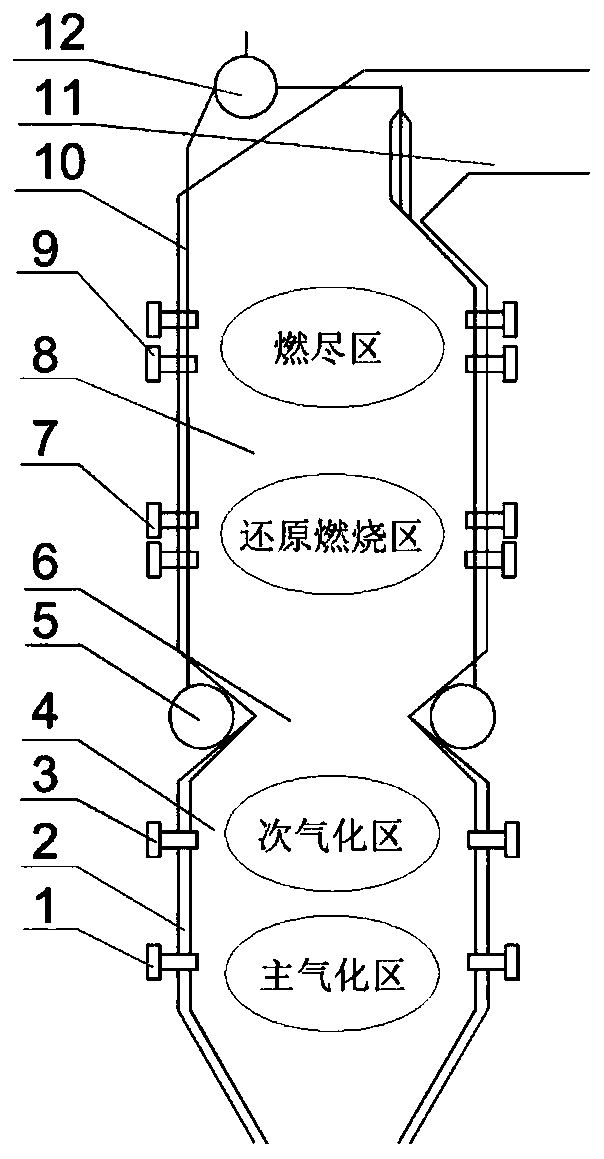

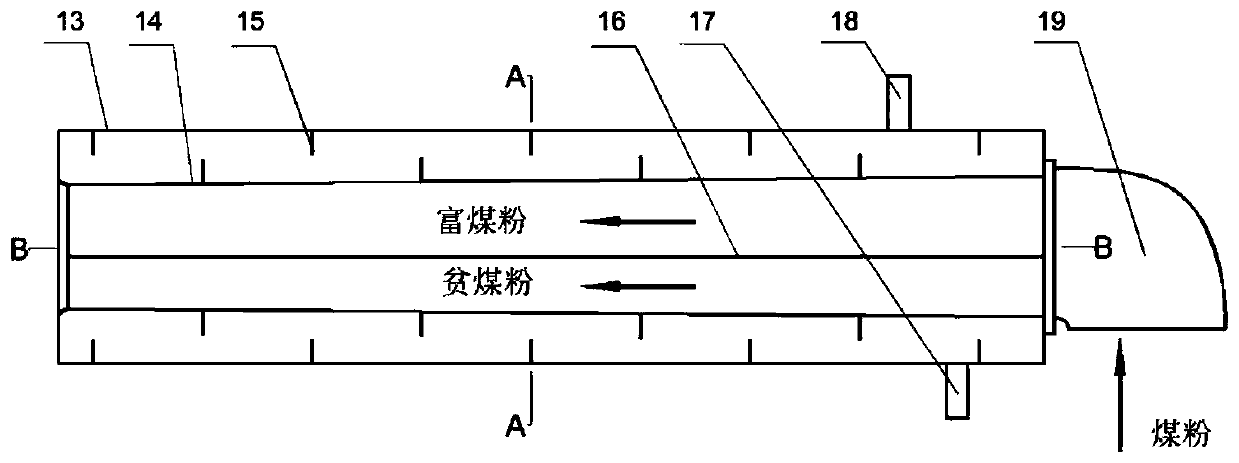

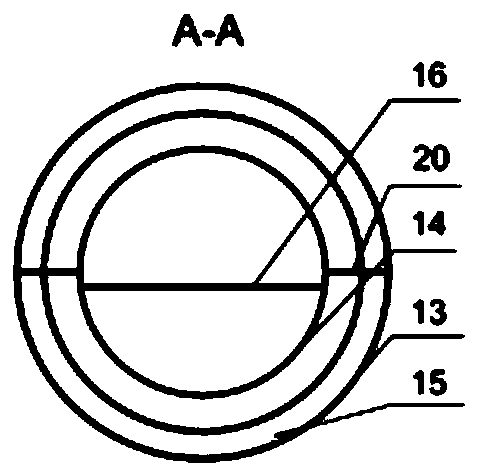

[0028] Such as figure 1 Shown: the inner wall of the gasification furnace 4 is provided with a refractory layer 2 to prevent the internal temperature of the gasification furnace 4 from being too low, to ensure the smooth progress of the pyrolysis and gasification of pulverized coal, to precipitate a large amount of reducing gas and to suppress NO X The production.

[0029] During the working process of the boiler gasification device, 85-90% of the pulverized coal is injected into the gasification furnace 4 through the primary fuel nozzle 1, forming a swirling flow in the furnace, strengthening gas disturbance and forming a better aerodynamic field, At this time, a main gasification zone is formed inside the gasification furnace 4. Control the air volume to ensure that the excess air coefficient α in the main gasification zone is between 0.2-0.5, to ensure that the pulverized c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com