Explosion-preventing flame-retarding intercooler and gas engine device comprising same

A cooler and flame arrester technology, which is applied to combustion engines, machines/engines, internal combustion piston engines, etc., can solve problems such as cylinder jacking accidents, intercooler air intake efficiency and cooling effect reduction, intercooler system failure, etc., to achieve Improve the sealing effect and increase the fire resistance and fire extinguishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

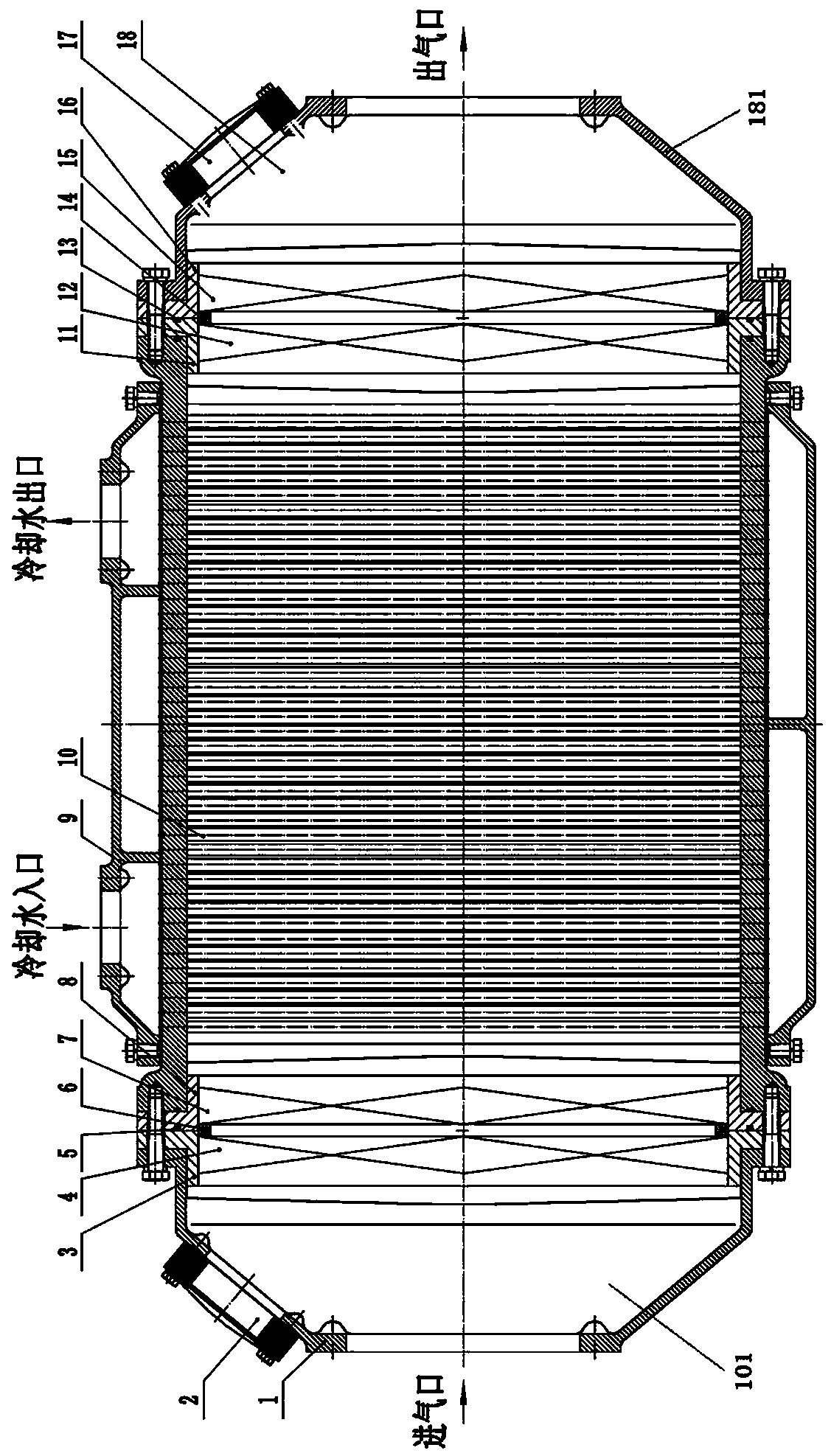

[0062] In this embodiment, the first gas outlet fire arresting structure includes:

[0063] The first gas outlet flame arrester seat 11, the first gas outlet flame arrester seat 11 is set at the end of the cooling water cavity 9 close to the gas outlet, the outer diameter of the first gas outlet flame arrester seat 11 is fitted to the inner diameter of the cooling water cavity 9 , when the first outlet flame arrester seat 11 is in use, it is attached to the inner wall of the cooling water chamber 9, thereby ensuring that the flame will not spread between the first outlet flame arrester seat 11 and the cooling water chamber 9; and

[0064] At least one first gas outlet flame arrester core 12, the first gas outlet flame arrester core 12 is fixed in the first gas outlet flame arrester seat 11, when in use, by setting different numbers of first gas outlet flame arrester cores 12 to Increase fire extinguishing effect;

[0065] The second gas outlet fire arresting structure include...

Embodiment 2

[0071] As a preferred embodiment of Embodiment 1, in this embodiment, an air outlet intermediate spacer ring 14 is arranged between the first air outlet flame arrester core 12 and the second air outlet flame arrester core 15; The inner wall of the first gas outlet flame arrester seat 11 and the second gas outlet flame arrester seat 16 are connected. The spacer ring 14 in the air outlet can effectively ensure that there is a gap between the first air outlet flame arrester core 12 and the second air outlet flame arrester core 15. The second outlet flame arrester seat ring 16 is connected so that it becomes a whole and is easy to disassemble.

Embodiment 3

[0073] As a preferred embodiment of the above embodiment, in this embodiment, the intercooler and the air outlet are detachably connected, so in order to ensure the airtightness of the intercooler, an air outlet seal is provided at the connection between the intercooler and the air outlet Circle 13.

[0074] An air outlet sealing ring 13 is also arranged at the communication part between the intercooler and the air outlet;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com