A prefabricated bamboo-wood beam column and its connectors, disassembly method, and bamboo-wood structure node

A beam-column connection and connector technology, applied in truss-type structures, columns, girders, etc., can solve problems such as height and span constraints of bamboo and wood structures, damage to the mechanical properties of beam-column ends, and difficulty in disassembly and later recycling. Achieve the effect of solving the exposed steel structure, improving the overall structural performance of the house, and fast assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

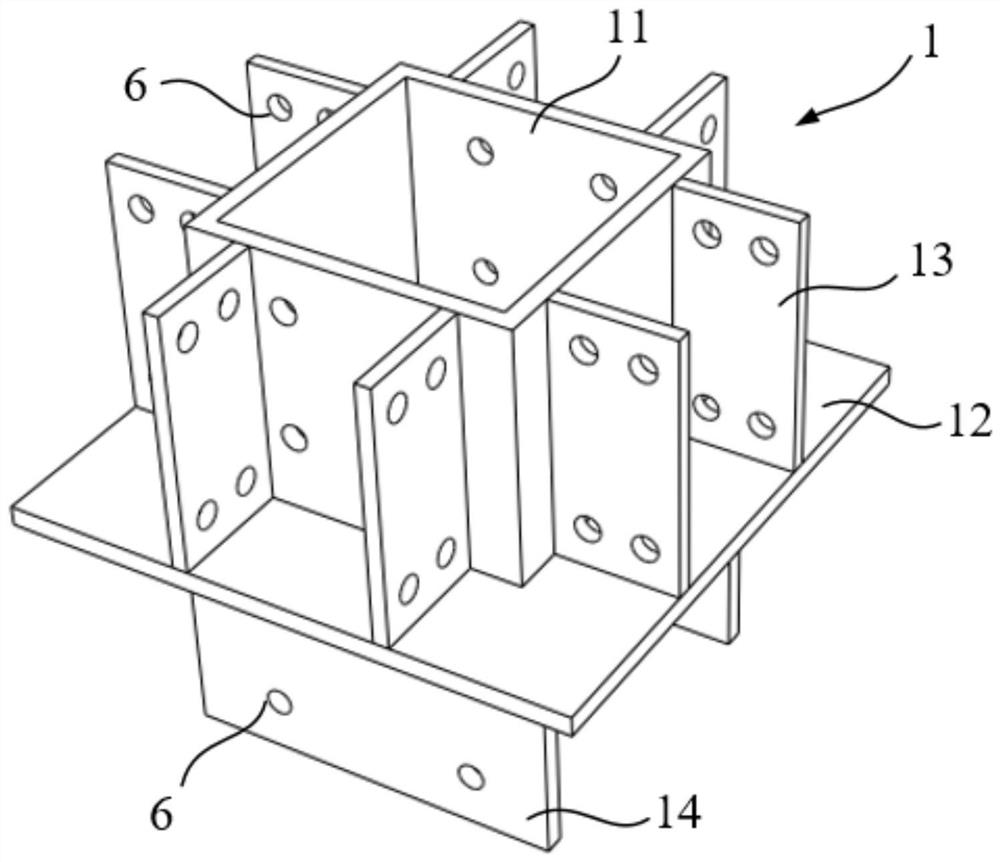

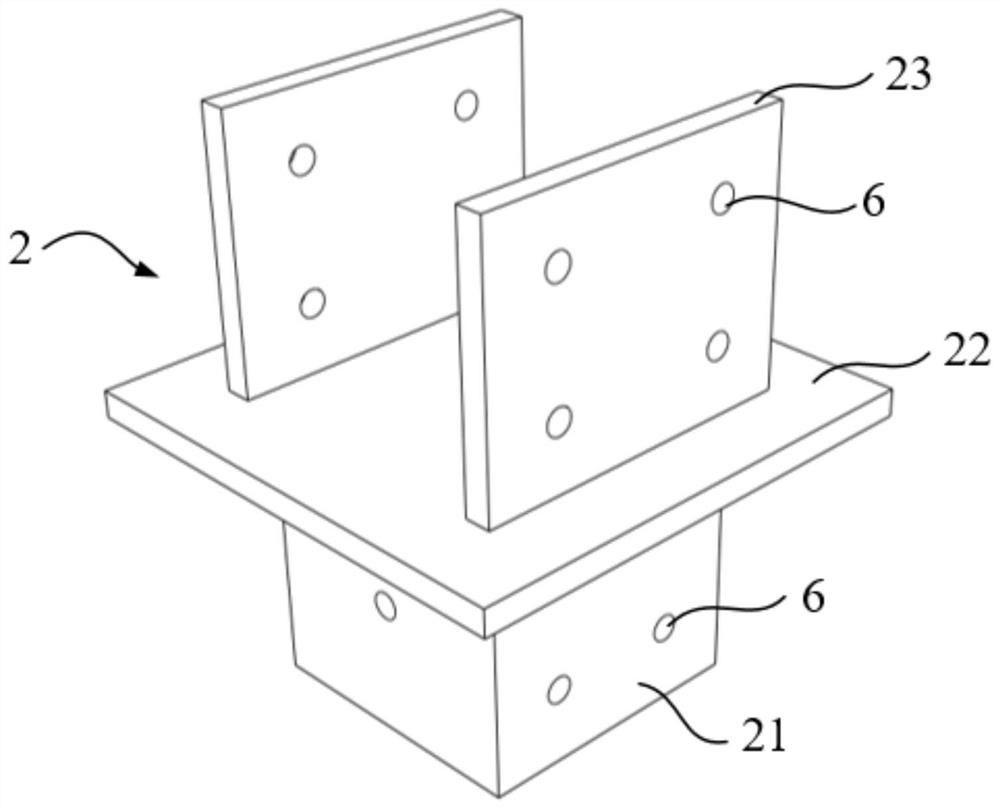

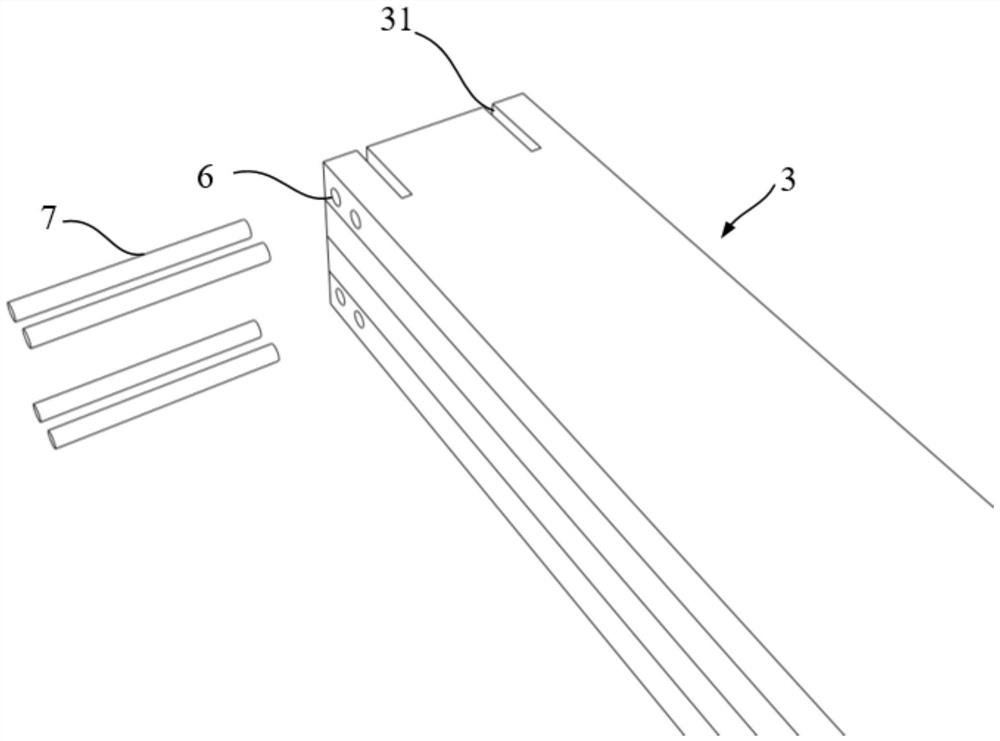

[0058] Such as figure 1 with figure 2 As shown, the beam-column connector of the present invention includes a central piece 1, a column end piece 2 and a connecting piece 7, the column end piece 2 is nested in the central piece 1, and the central piece 1 and the column end piece 2 are fixed by the connecting piece 7 . The beam-column connector of the embodiment of the present invention is introduced in detail below: the center piece 1 includes a center piece casing 11, a center piece base plate 12, a center piece upper fin 13 and a center piece lower fin 14, and the center piece casing 11 is arranged on Above the centerpiece substrate 12, the cross-sectional shape of the centerpiece casing 11 is not limited to figure 1 The rectangle shown in , can also be circular, elliptical, polygonal or other irregular shapes, but no matter how the cross-sectional shape of the center piece casing 11 changes, as long as it can ensure that it is consistent with the column end pieces desc...

Embodiment 2

[0067] On the basis of Embodiment 1, the cross-section of the center piece casing 11 is still rectangular, and the difference with Embodiment 1 is that the four sides of the center piece casing 11 are not all provided with a The upper fins 13 of the center piece are assembled, but only a set of upper fins 13 of the center piece are respectively arranged on the two opposite sides. The center piece 1 designed in this way is more suitable for the outermost layer of the bamboo-wood structure node; , only the upper fins 13 of the center piece are provided on the two adjacent side surfaces of the center piece casing 11, and the center piece 1 designed in this way is more suitable for the edge of the bamboo-wood structure node. Flexible adjustment of the setting position of the fins 13 on the center piece can reduce the processing cost of the center piece 1 and further reduce the construction cost.

Embodiment 3

[0069] On the basis of Embodiment 1, the difference from Embodiment 1 is that the connecting hole 6 is a rectangular through hole with a square cross section, and a groove is arranged on each side of the inner wall of the rectangular through hole. The grooves are arranged and distributed along the circumferential direction of the rectangular through hole, and extend toward the axial direction of the rectangular through hole. In order to make the connection and fixation of the connecting piece 7 better, the connecting piece 7 is now a cross section that matches the rectangular through hole It is a rectangular rod, and each side of the rectangular rod is correspondingly provided with a protrusion matching the groove.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com