Reducing furnace for preparing sponge hafnium

A technology of reduction furnace and sponge, which is applied in the field of reduction furnace for preparing sponge hafnium, can solve problems such as rising temperature of melting tank, poor product quality, and difficulty in crushing, so as to improve product recovery rate, facilitate later crushing, and increase contact area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below with reference to the accompanying drawings.

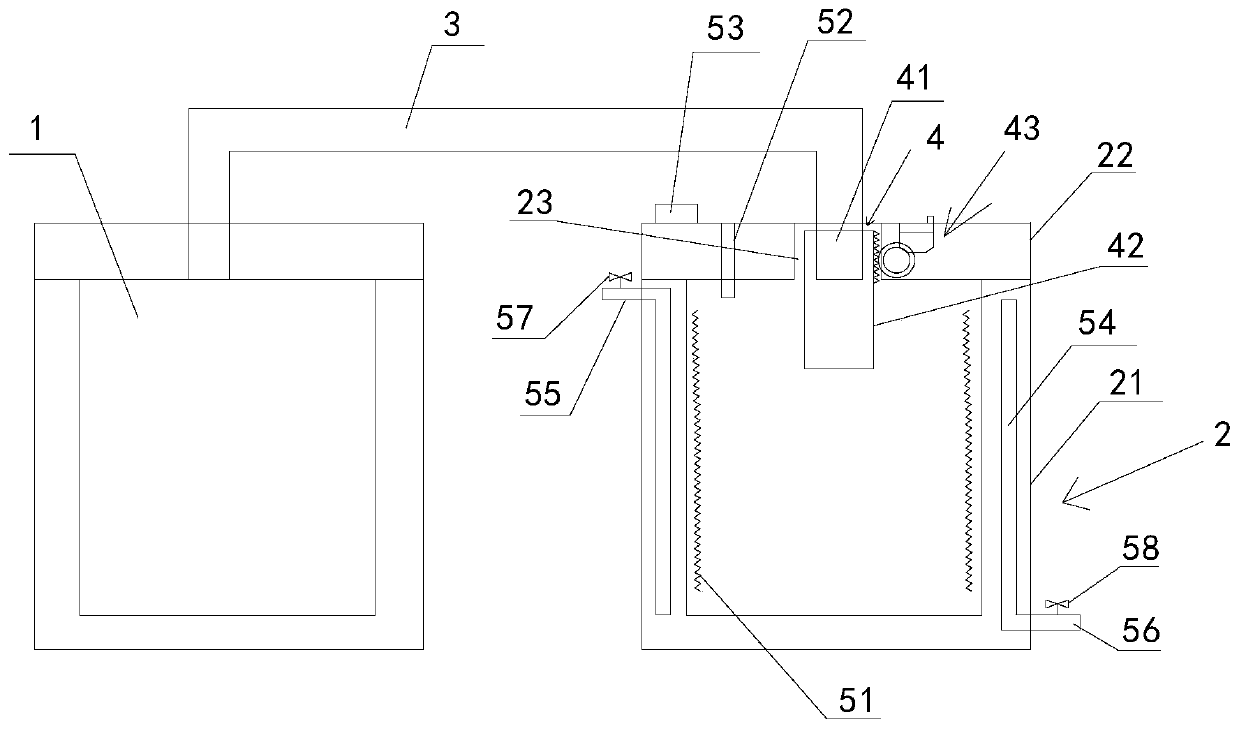

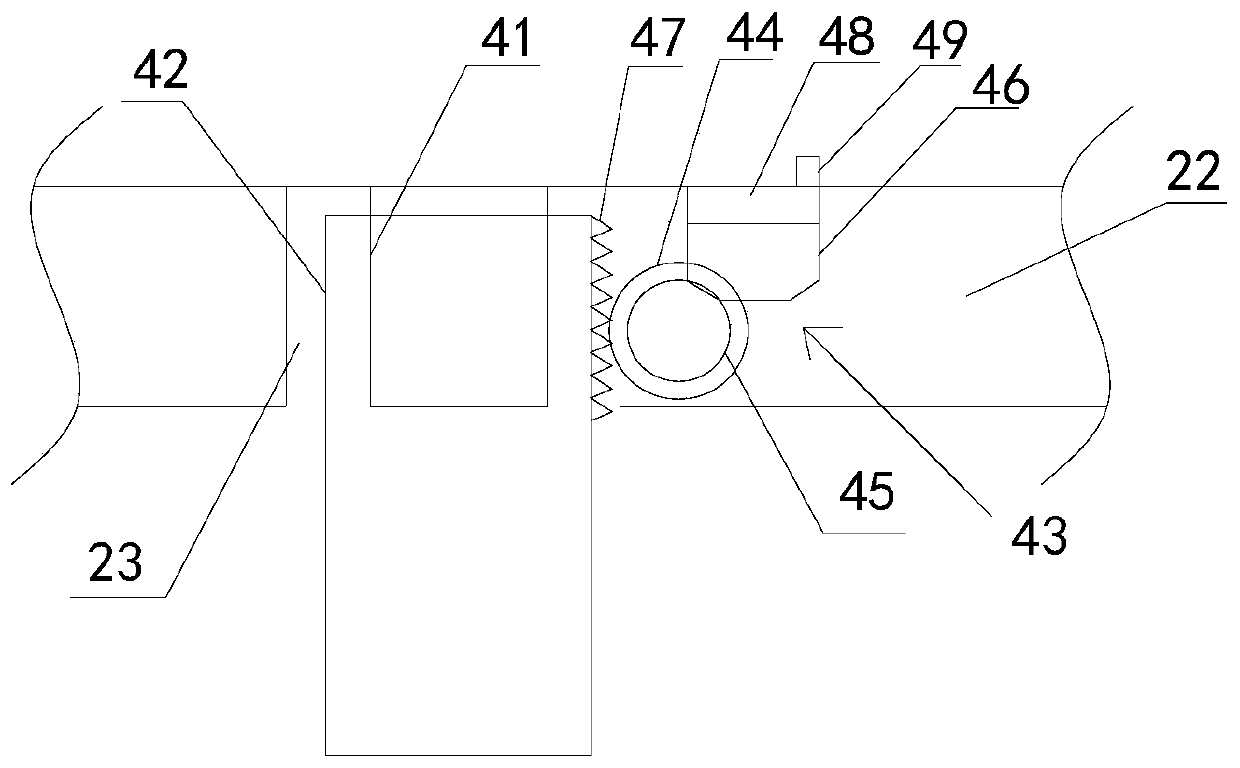

[0019] like figure 1 and figure 2 Shown, a kind of reduction furnace of preparing sponge hafnium, comprises hafnium tetrachloride sublimation furnace 1, magnesium ingot melting furnace 2 and communication pipe 3, and communication pipe 3 communicates hafnium tetrachloride sublimation furnace 1 and magnesium ingot melting furnace 2, four Hafnium chloride sublimation furnace 1 and magnesium ingot melting furnace 2 are resistance heating furnaces, and hafnium tetrachloride sublimation furnace 1 is used for the HfCl in the furnace Heating and subliming into gas, HfCl gas enters magnesium ingot melting furnace 2 by communicating pipe 3 Inside, resistance heating can be provided around the pipe wall of the communication pipe 3, and the magnesium ingot melting furnace 2 can heat the magnesium ingot in the furnace into a molten state.

[0020] The magnesium ingot me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com