Heteropolyacid ammonium salt catalyst and preparation method thereof

A heteropolyacid ammonium salt and catalyst technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of reducing catalyst activity, affecting product selectivity, weakening catalyst acidity, etc., to achieve Effect of reduced interaction, high selectivity, enhanced interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

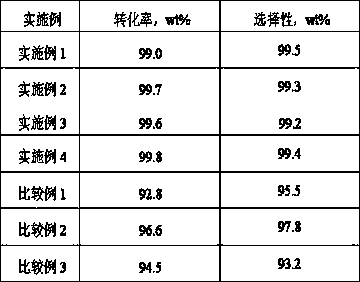

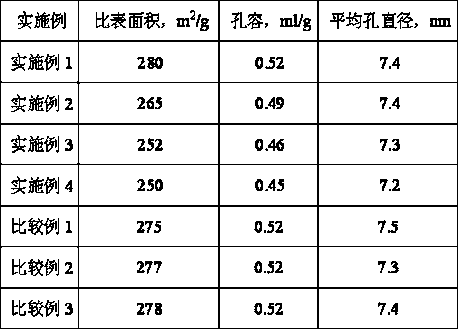

Examples

Embodiment 1

[0044] (1) Preparation of catalyst:

[0045] Weigh 3.8g phosphoric acid H 3 PO 4 (concentration 85 wt%) was dissolved in 100mL water, added to 85.1g alumina carrier (pore volume 0.70mL / g, specific surface area 300m 2 / g, spherical shape, particle diameter 0.4mm~0.6mm), mixed evenly and dried at 70°C for 4h, then heated to 110°C and dried for 4h to prepare catalyst precursor A; then added to 200mL containing 11.8g dodecyl In the cyclohexane solution of trimethoxysilane, react at 50°C for 3.0h, and dry at 70°C for 8h to obtain catalyst precursor B; ℃ low temperature reaction bath, then add 150mL aqueous solution containing 42.6g citric acid, soak for 30min, pour out the solution, then add 150mL ammonium carbonate solution with a mass fraction of 30% and soak for 5min, pour out the solution, then add 100mL An aqueous solution containing 10.4g of phosphotungstic acid was impregnated for 5 minutes and then filtered, and the obtained solid was dried at 110°C for 8.0h at a relativ...

Embodiment 2

[0051] (1) Preparation of catalyst:

[0052] Weigh 7.6g phosphoric acid H 3 PO 4 (concentration 85 wt%) was dissolved in 100mL water, added to 76.4g alumina carrier (pore volume 0.70mL / g, specific surface area 300m 2 / g, spherical shape, particle diameter 0.4mm~0.6mm), mixed evenly and dried at 70°C for 4h, then heated to 110°C and dried for 4h to prepare catalyst precursor A; then added to 200mL containing 21.7g hexadecyl In the cyclohexane solution of trimethoxysilane, react at 50°C for 3.0h, and dry at 70°C for 8h to obtain catalyst precursor B; then add it to 200mL0# diesel oil, filter after soaking for 30min, and place the obtained material in- In a low-temperature reaction bath at 10°C, add 150mL of an aqueous solution containing 76.4g of citric acid, soak for 30 minutes, pour out the solution, then add 150mL of ammonium carbonate solution with a mass fraction of 30%, and soak for 5 minutes, pour out the solution, and then add 100mL of an aqueous solution containing 1...

Embodiment 3

[0058] (1) Preparation of catalyst:

[0059] Weigh 11.4g phosphoric acid H 3 PO 4 (concentration 85 wt%) was dissolved in 100mL water, added to 67.3g alumina support (pore volume 0.70mL / g, specific surface area 300m 2 / g, spherical shape, particle diameter 0.4mm~0.6mm), mixed evenly and dried at 70°C for 4h, then heated to 110°C and dried for 4h to prepare catalyst precursor A; then added to 200mL containing 34.0g octadecyl In the cyclohexane solution of trimethoxysilane, react at 50°C for 3.0h, and dry at 70°C for 8h to obtain catalyst precursor B; In a low-temperature reaction bath at -20°C, add 150mL of an aqueous solution containing 80.8g of citric acid, soak for 30 minutes, pour out the solution, then add 150mL of ammonium carbonate solution with a mass fraction of 30%, soak for 5 minutes, and pour out the solution. Then add 100mL of an aqueous solution containing 20.8g of phosphotungstic acid, filter after soaking for 5min, dry the obtained solid at 110°C for 8.0h at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dew point | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com