Zirconium nitride powder and method for producing same

A manufacturing method and technology of zirconium nitride, applied in chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., can solve problems such as unsuitability for insulation, and achieve the effects of inhibiting sedimentation, high shading performance, and improving nitriding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

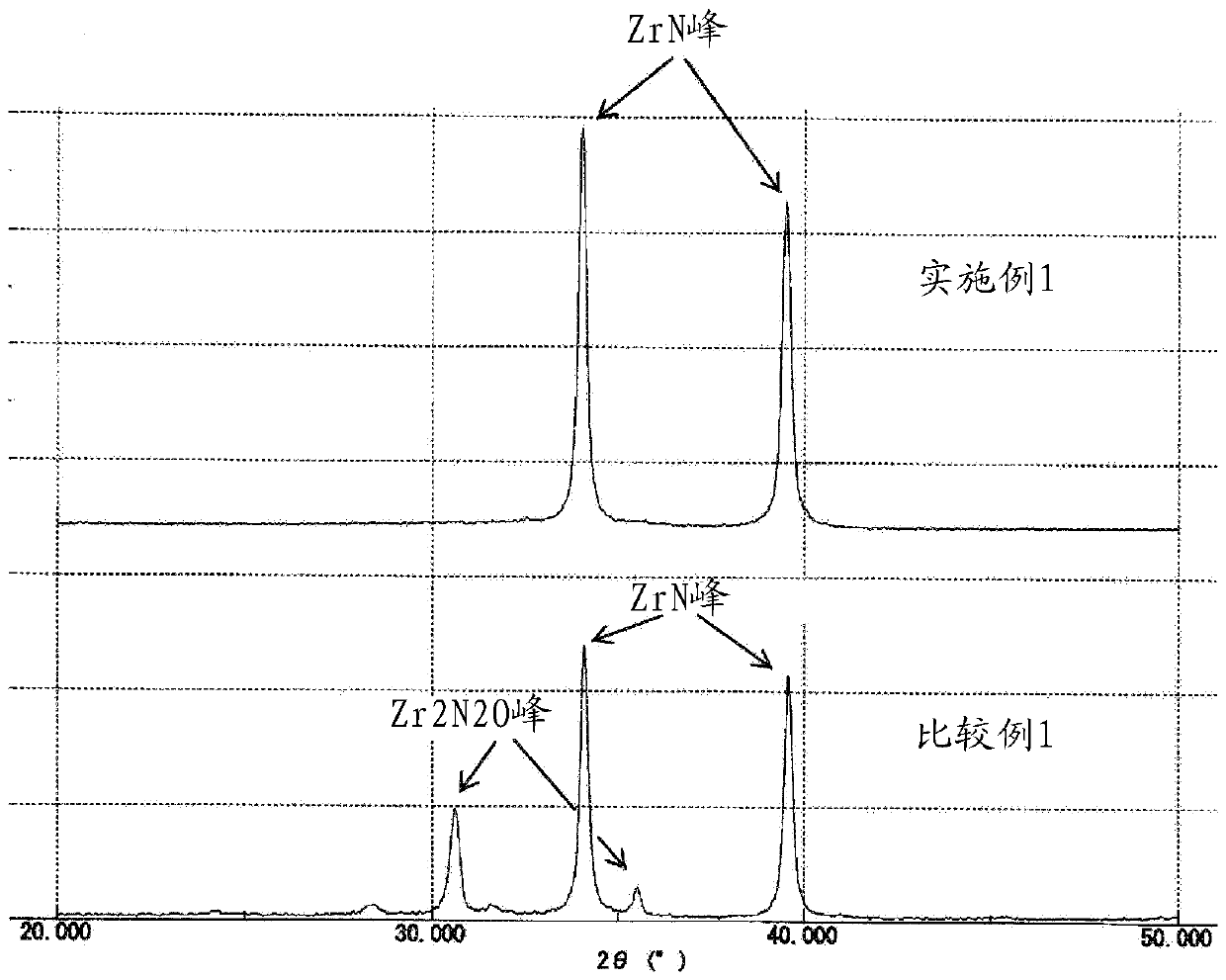

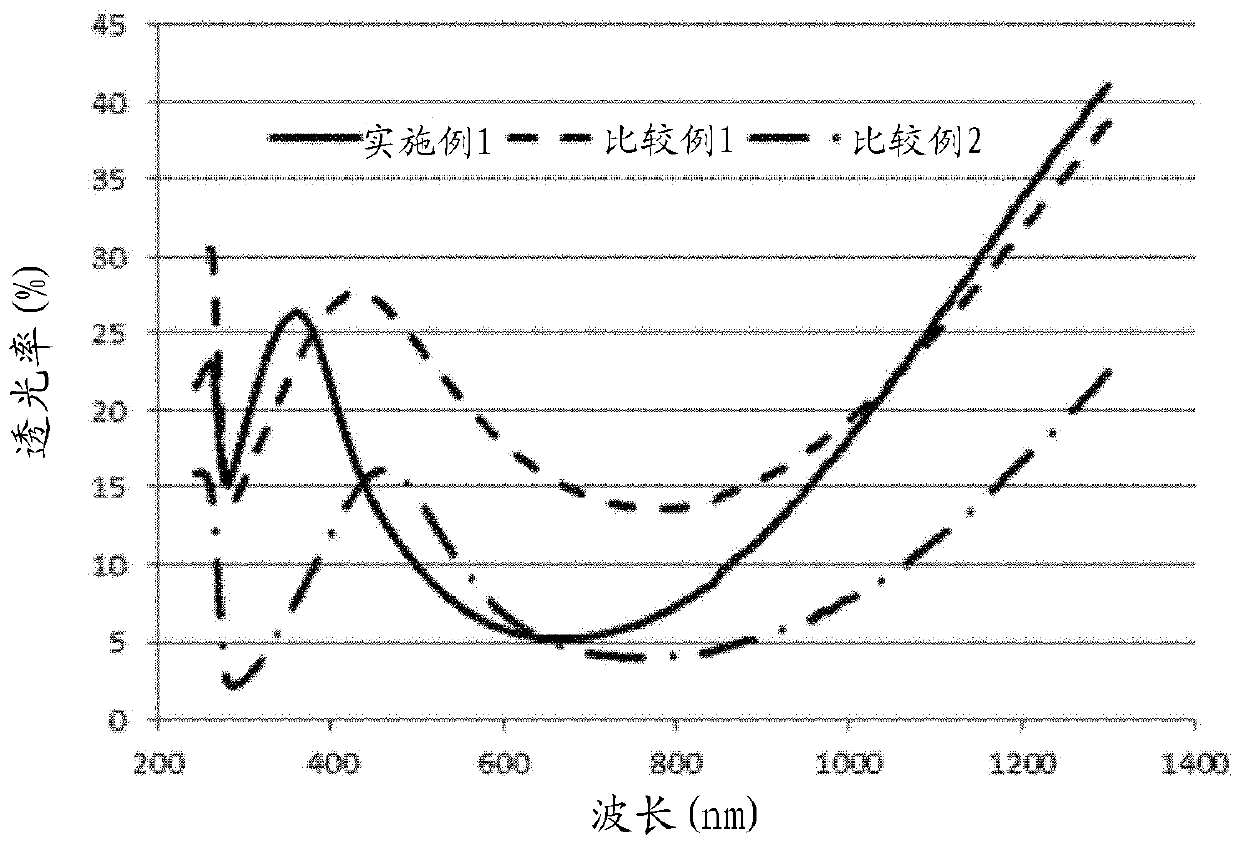

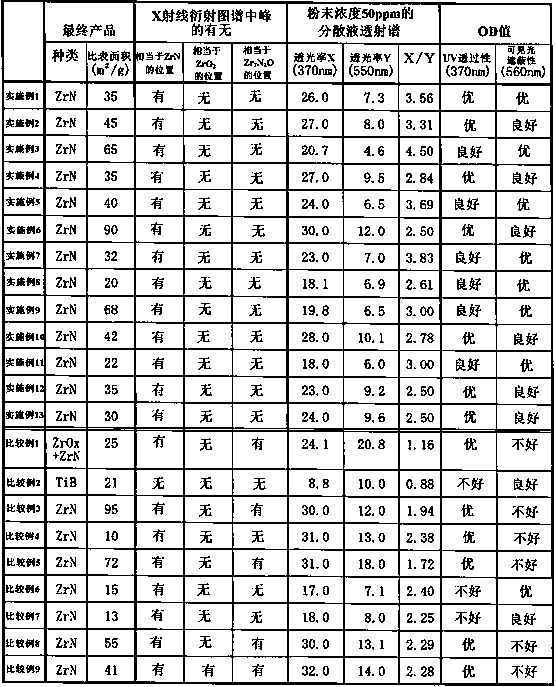

Embodiment 1

[0066] 7.3 g of metallic magnesium powder with an average primary particle size of 150 μm and 3.0 g of magnesium nitride powder with an average primary particle size of 200 nm were added to 7.4 g of monoclinic zirconia powder, and a graphite boat was placed in a quartz glass tube. The reaction device was used for uniform mixing, and the average primary particle diameter of the monoclinic zirconia powder calculated from the specific surface area measured by the BET method was 50 nm. At this time, the added amount of metal magnesium is 5.0 times mole of zirconium dioxide, and the added amount of magnesium nitride is 0.5 times mole of zirconium dioxide. This mixture was fired at a temperature of 700° C. for 60 minutes in a nitrogen atmosphere to obtain a fired product. Disperse the calcined product in 1 liter of water, slowly add 10% hydrochloric acid to bring the pH to 1 or higher, and wash while keeping the temperature below 100°C, then adjust the pH to 7 to 8 with 25% ammonia ...

Embodiment 2

[0068] The metallic magnesium powder identical with embodiment 1 is changed into 4.4g (3.0 times mole of zirconium dioxide), makes reaction gas be the mixed gas of nitrogen and hydrogen, in the ratio of their volume % (N 2 :H 2 ) was 90%: 10% of the mixed gas atmosphere, except that the firing time was 30 minutes, and zirconium nitride powder was produced in the same manner as in Example 1.

Embodiment 3

[0070] 7.4 g of zirconium dioxide powder identical to Example 1 was dispersed in ethanol, and the mixed liquid was added and mixed to a silicate sol-gel liquid (0.1522 g of silicon dioxide component) mainly composed of ethyl silicate, A slurry having a solid content concentration of 30% by mass was prepared. The slurry was dried with a box dryer at a temperature of 70° C. for 120 minutes in an air atmosphere to obtain a zirconia powder coated with silica and having an average primary particle diameter of 50 nm. In this powder, zirconia contains 3.0% by mass of silicon dioxide (SiO 2 ). 8.8 g of metallic magnesium powder with an average primary particle diameter of 300 μm and 2.1 g of magnesium nitride powder with an average primary particle diameter of 500 nm were added to 7.5 g of this zirconia powder, and uniformly mixed in the same manner as in Example 1. At this time, the amount of metal magnesium added was 6.0 times the mole of zirconia, and the amount of magnesium nitr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com