Multi-degree-of-freedom ultrasonic motor driven by cylindrical and disc hybrid

A technology of hybrid drive and ultrasonic motor, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc., can solve the problems of low integration, less degree of freedom, and large volume , to achieve the effect of high integration, simple and compact structure, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

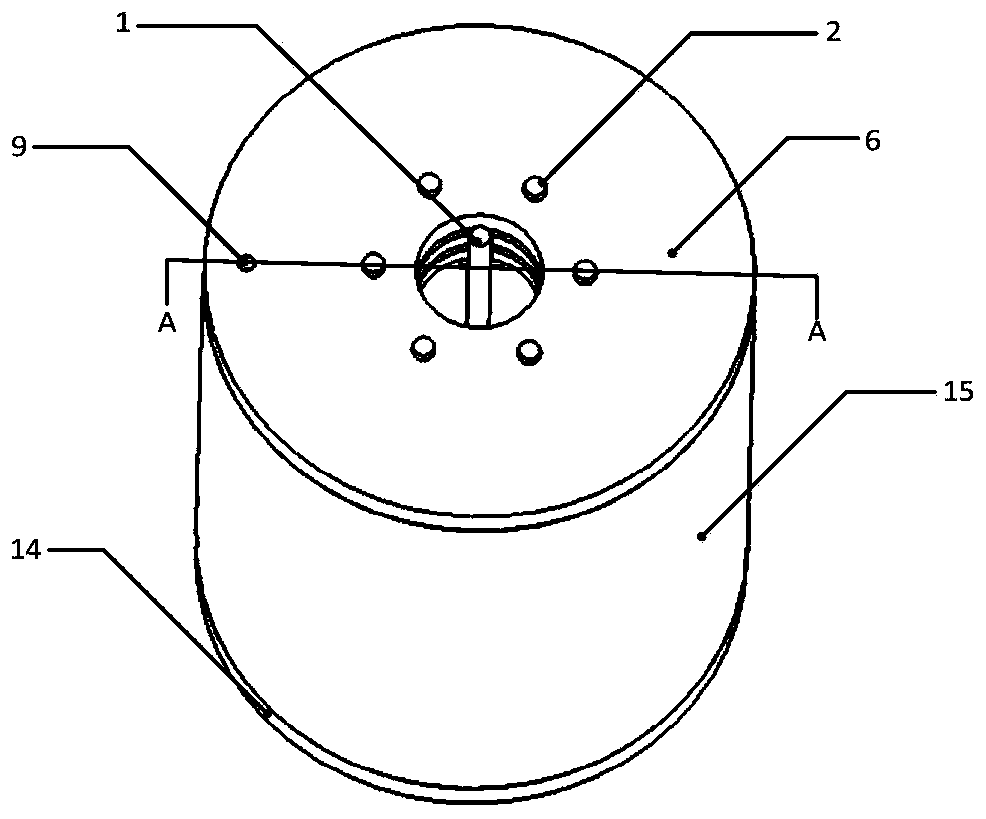

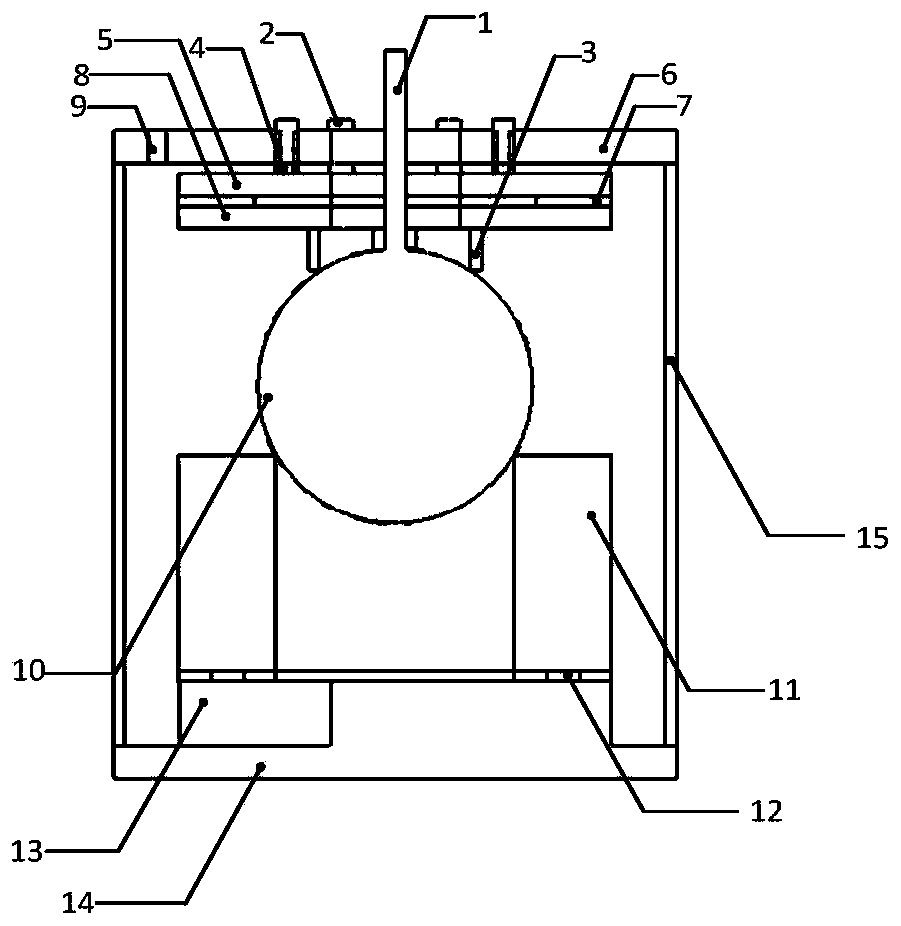

[0029] see Figure 1-Figure 10 , a columnar and disk hybrid drive multi-degree-of-freedom ultrasonic motor based on a new piezoelectric ceramic arrangement is now described.

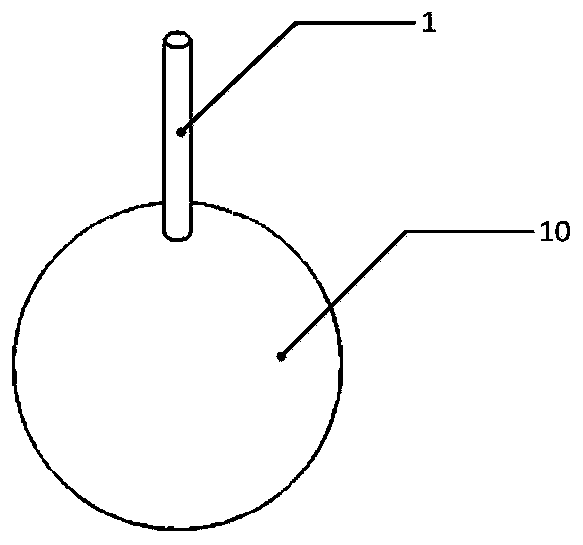

[0030] As a specific embodiment of the present invention, the electric columnar and disc-shaped hybrid drive multi-degree-of-freedom ultrasonic motor, the technical solution adopted in the present invention is: see figure 1 , a columnar and disk-shaped mixed-drive multi-degree-of-freedom ultrasonic motor, a double-stator multi-degree-of-freedom motor, including a casing and a rotor 10, is characterized in that: the rotor is a spherical body, and the upper end is fixedly connected to the output shaft 1; it also includes a piezoelectric The drive rotation dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com