Lever-type sample preparation machine for disturbed soil triaxial compression test and sample preparation method thereof

A triaxial compression, lever-type technology, applied in the preparation of test samples, etc., can solve the problems of cumbersome sample preparation steps, noise pollution, complicated processes, etc. The effect of suppressing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

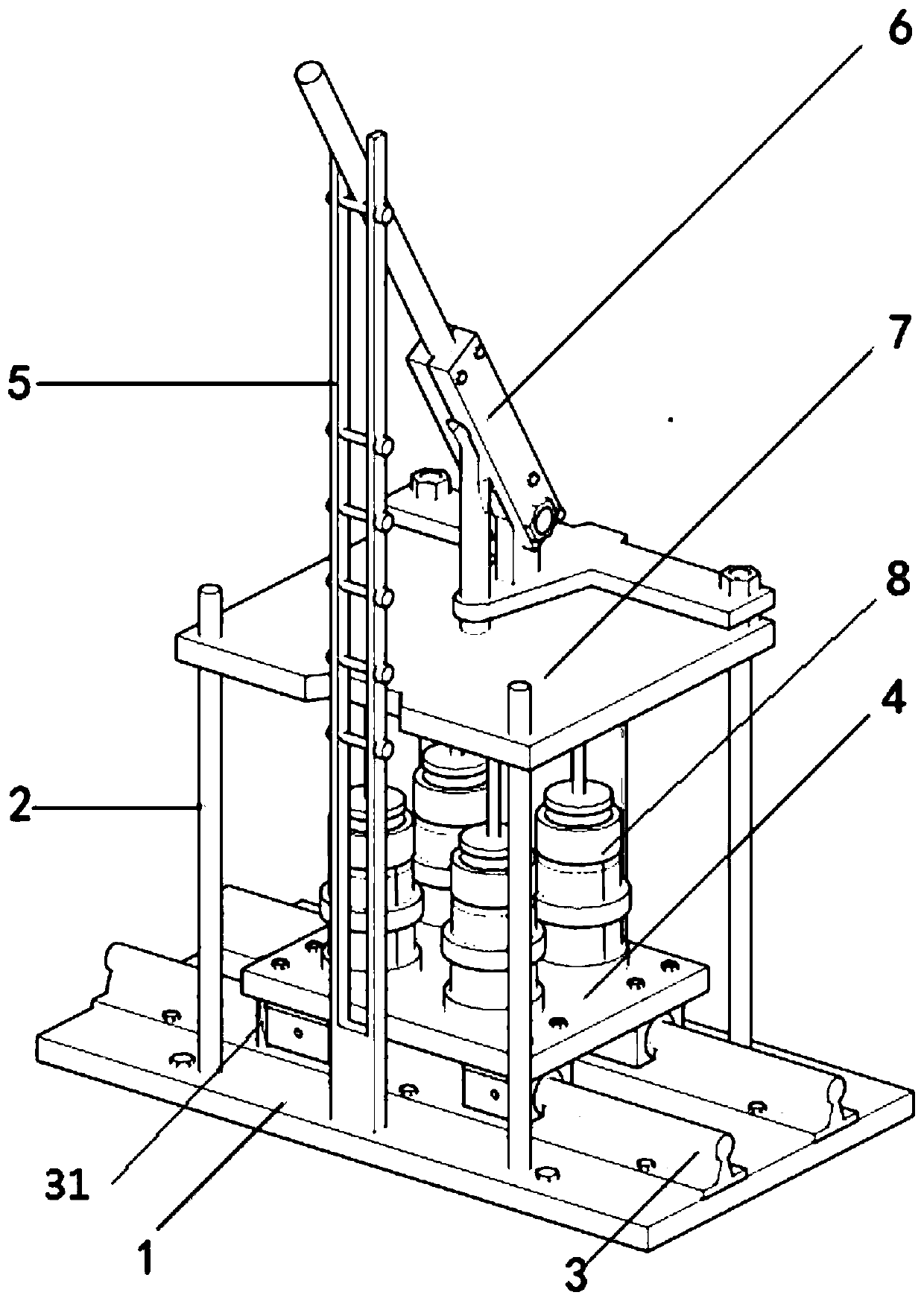

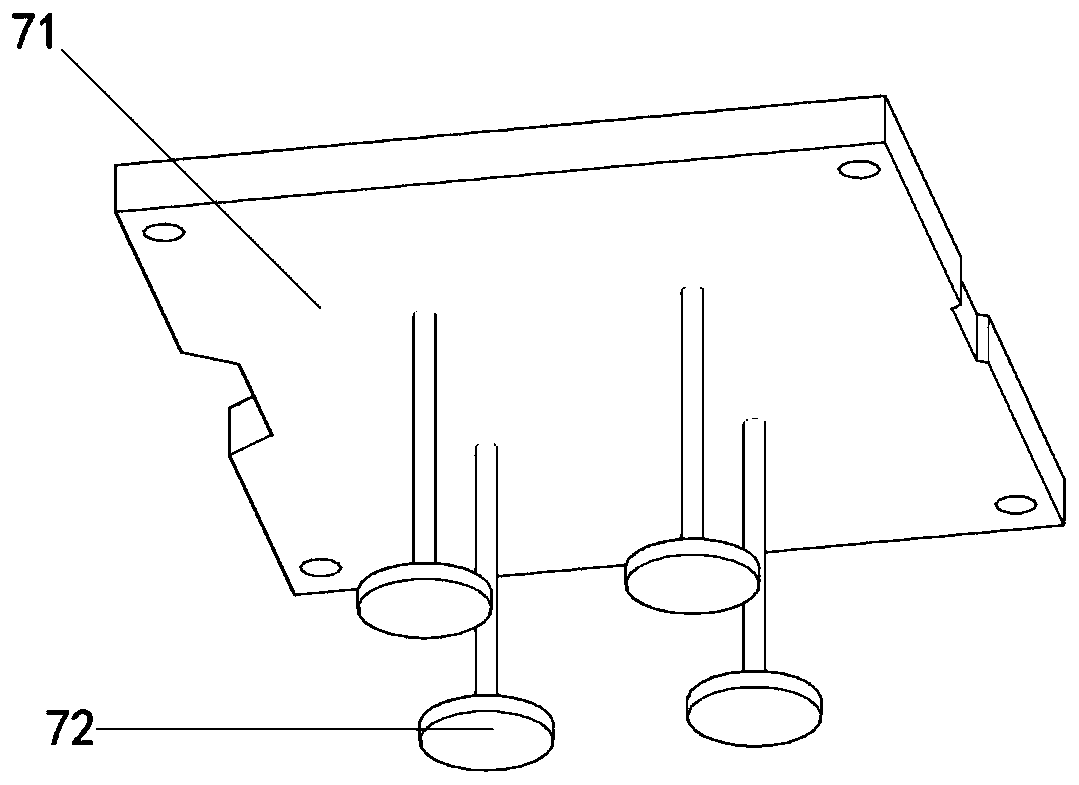

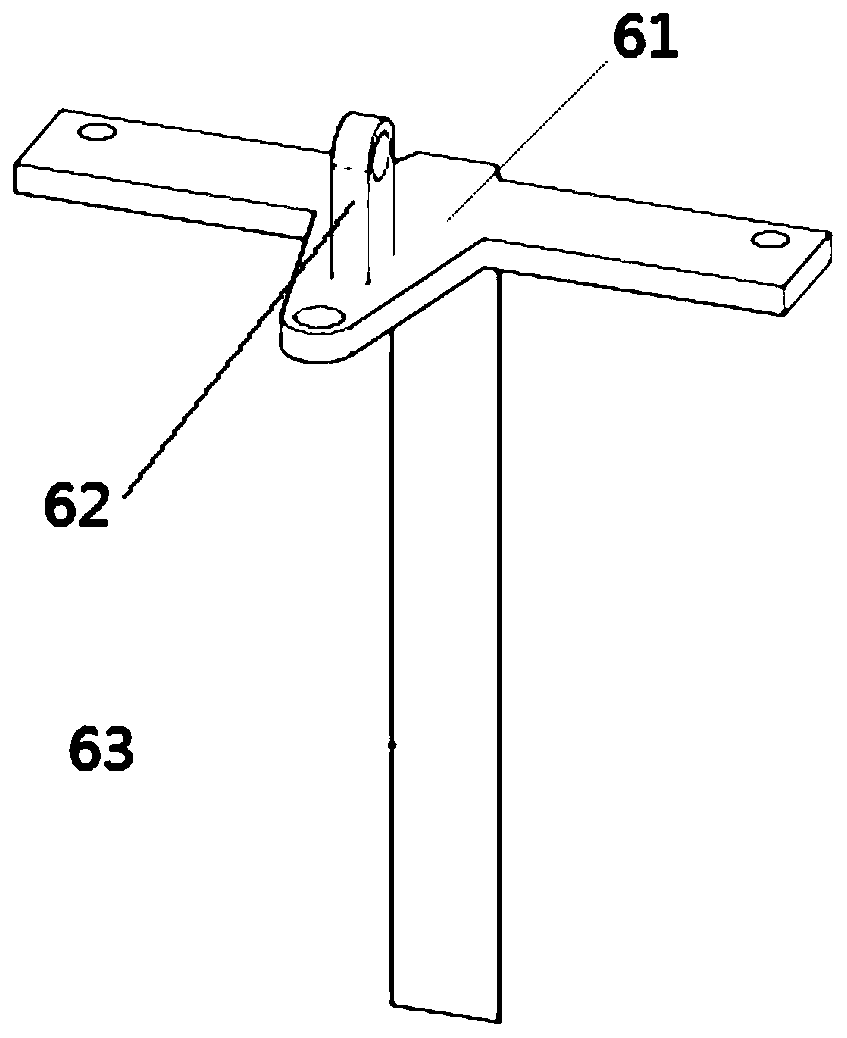

[0058] Such as figure 1 As shown, the lever-type sample making machine for the triaxial compression test of disturbed soil disclosed in this embodiment includes a bottom plate 1, a vertical rod 2, a linear guide rail 3, a mold fixing plate 4, a positioning frame 5, a lever assembly 6, a lifting Plate assembly 7, sample preparation mold 8.

[0059] The base plate 1 is a rectangular plate, and there are two sets of linear guide rails 3, which are symmetrically fixed on both sides of the central plane of the base plate 1 in the width direction. This embodiment adopts SBR linear guide rail, and two sliders are arranged on the guide rail, and a vertical magnetic limit rod 31 is fixed on the bottom support of the guide rail corresponding to the outer end of one of the sliders. figure 1 The middle magnetic limit lever is located at the outer end of the rear end slider.

[0060] The four corners of the bottom plate are fixed on the flat ground by anchor bolts.

[0061] The mold fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com