Biomedical silicon rubber with antibacterial property

A biomedical and silicone rubber technology, applied in the field of biomedical antibacterial, can solve the problems of nano-silver slow release, and achieve the effect of low cytotoxicity, low cytotoxicity and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

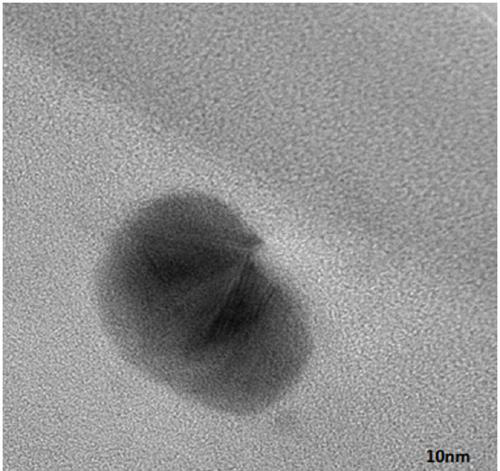

[0028] Prepare graphene oxide according to the Hummers method, dry it to obtain graphite oxide, and reduce the obtained graphite oxide to graphene by high-temperature calcination in an intelligent tube furnace; place the graphene solution under alkaline conditions in 100ml of polytetrafluoroethylene In the lining, hydrothermal reaction was carried out at 180°C for 12 hours, cooled at room temperature, filtered, and dialyzed to obtain graphene quantum dots (GQDs).

[0029] Add 60ml of ethanol to the beaker, add 10mg of the prepared nano-silver particles, ultrasonically stir for 1h, add 1ml of silane coupling agent, and ultrasonically for 1h to obtain Ag-silane coupling agent mixed solution, add 20ml of absolute ethanol to the beaker, add 1 mg of graphene quantum dots, ultrasonication for 30 minutes, and magnetic stirring for 30 minutes at room temperature to obtain a dispersion of graphene quantum dots. Pour the dispersion of graphene quantum dots into the purified Ag-silane co...

Embodiment 2

[0032] Add 70ml of ethanol to the beaker, add 15mg of the prepared silver nanoparticles, sonicate for 1h, add 1ml of silane coupling agent, and sonicate for 1h to obtain the Ag-silane coupling agent mixture; add 20ml of absolute ethanol to the beaker, add 1mg Graphene quantum dots, ultrasonication for 30 minutes, and magnetic stirring for 30 minutes at room temperature to obtain a dispersion of graphene quantum dots. Pour the dispersion of graphene quantum dots into the purified Ag-silane coupling agent solution, ultrasonically disperse for 1 h, magnetically stir for 1 h, and dry in vacuum at 60° C. to obtain graphene quantum dot-coated silver nanoparticles.

[0033] Add 50ml of liquid silicone rubber into a beaker and stir for 10min; take 1g of graphene quantum dot-coated nano-silver antibacterial agent and place it in a 50ml beaker, add 10 parts of solvent, ultrasonicate for 30min, then add it to the liquid silicone rubber and stir for 10min; Add 1.5ml of curing agent to the...

Embodiment 3

[0035] Add 80ml of ethanol to the beaker, add 20mg of the prepared silver nanoparticles, sonicate for 1h, add 1ml of silane coupling agent, and sonicate for 1h to obtain the Ag-silane coupling agent mixture; add 20ml of absolute ethanol to the beaker, add 1mg Graphene quantum dots, ultrasonication for 30 minutes, and magnetic stirring for 30 minutes at room temperature to obtain a dispersion of graphene quantum dots. Pour the dispersion of graphene quantum dots into the purified Ag-silane coupling agent solution, ultrasonically disperse for 1 h, magnetically stir for 1 h, and dry in vacuum at 60° C. to obtain graphene quantum dot-coated silver nanoparticles.

[0036] Add 50ml of liquid silicone rubber into a beaker and stir for 10min; take 1g of graphene quantum dot-coated nano-silver antibacterial agent and place it in a 50ml beaker, add 10 parts of solvent, ultrasonicate for 30min, then add it to the liquid silicone rubber and stir for 10min; Add 2ml of curing agent to the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com