A counterbalanced AGV stacker

A stacker and counterweight technology, applied in the field of counterbalanced AGV stackers, can solve problems such as performance gaps and lack of product innovation, and achieve the effects of flexibility, high ergonomics, and small working space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

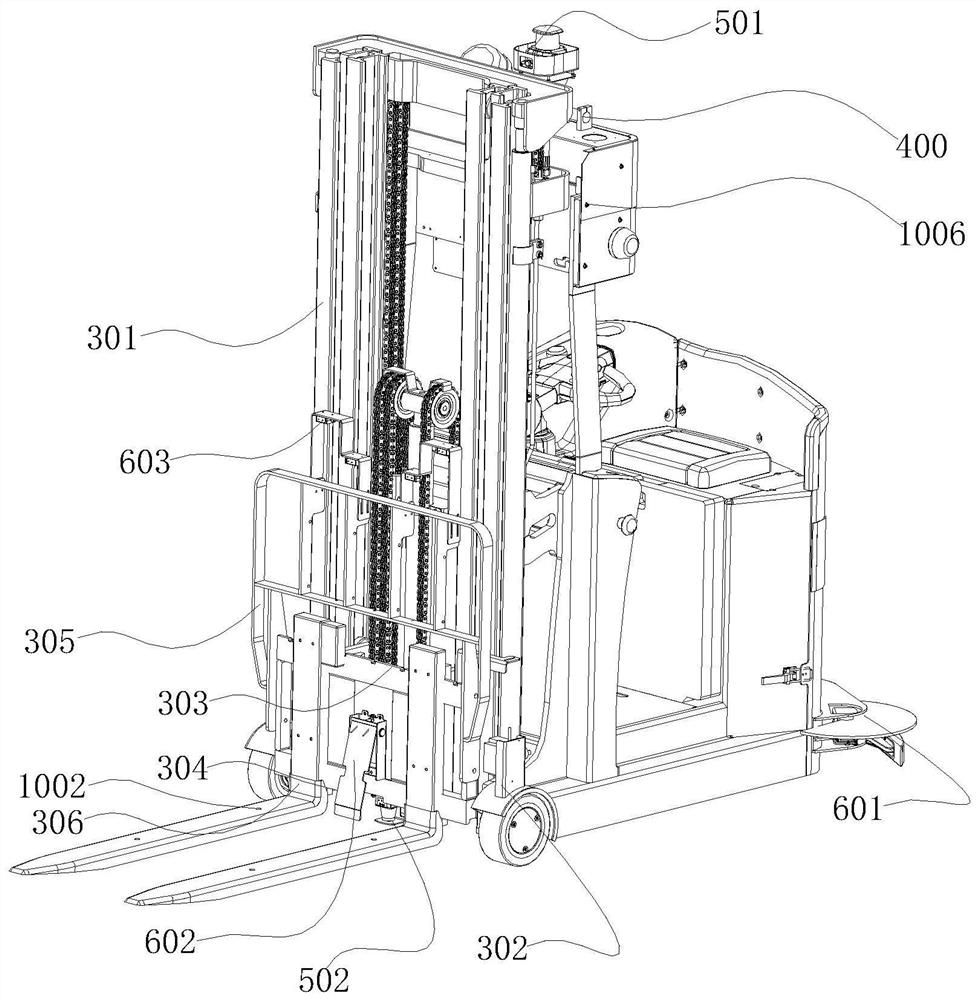

[0022] A counterbalanced AGV stacker, such as Figure 1-4 As shown, it includes a wireless weighing fork set on the frame 1001, a wireless weighing system 1000 for wirelessly weighing the goods loaded on the wireless weighing fork, and a control system for controlling the wireless weighing system 1000 , the wireless weighing system 1000 includes a first pressure sensor 1001 built in the inside of the wireless weighing fork and used to collect the weight of the goods loaded on the wireless weighing fork, a signal processor 1002 connected to the first pressure sensor 1001, and The touch screen display 1003 connected to the signal processor 1002, the wireless communication module 1006 for wireless communication connection, the control system includes the PLC central controller 400 to control the signal processor 1002, the signal processor 1002, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com