Alloy smelting slag treatment equipment for overturning furnace

A technology for processing equipment and alloys, used in lighting and heating equipment, furnaces, crucible furnaces, etc., can solve the problems of difficult coordination, dangerous cleaning process, low efficiency, etc., to improve cleaning and storage efficiency, avoid high temperature damage, and facilitate recycling. The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

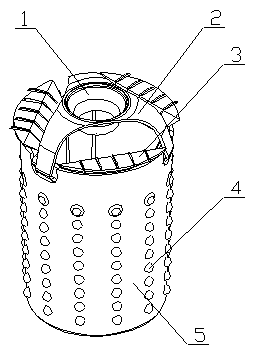

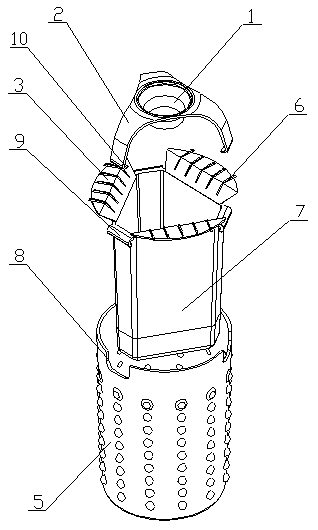

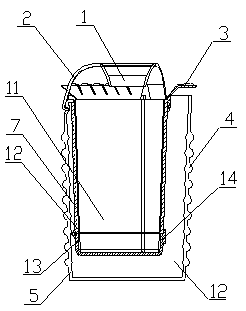

[0016] The slag treatment equipment for the alloy smelting of the overturning furnace of the present invention is realized in the following way: the slag treatment equipment for the alloy smelting of the overturning furnace of the present invention consists of a material guide ring (1), a box cover (2), a side material guide plate (3), and a spherical convex (4) , water bath box (5), guide bar (6), inner storage box (7), installation hanging groove (8), hanging buckle (9), connecting arm (10), accommodation cavity (11), filter plate ( 12), the bottom liquid collection tray (13) and the connecting buckle (14), the mouth of the water bath box (5) has three installation hanging slots (8) at equal angles, and the width of the installation hanging slots (8) It gradually decreases from the outside to the inside. The installation hanging groove (8) is provided with a non-slip pad on the groove wall, and the box cover (2) is placed above the mouth of the water bath box (5). The outer s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com