Composite drain board and design method thereof

A drainage board and drainage channel technology, which is applied in drainage, chemical instruments and methods, mining equipment, etc., can solve the problems of drainage capacity, compressive strength, inability to adapt to construction and paving convenience, high risk of clogging, and failure of drainage board crushing, etc. problems, to achieve the effect of being beneficial to the economics of the tunnel structure, reducing the size of the excavation section, and reducing the risk of fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

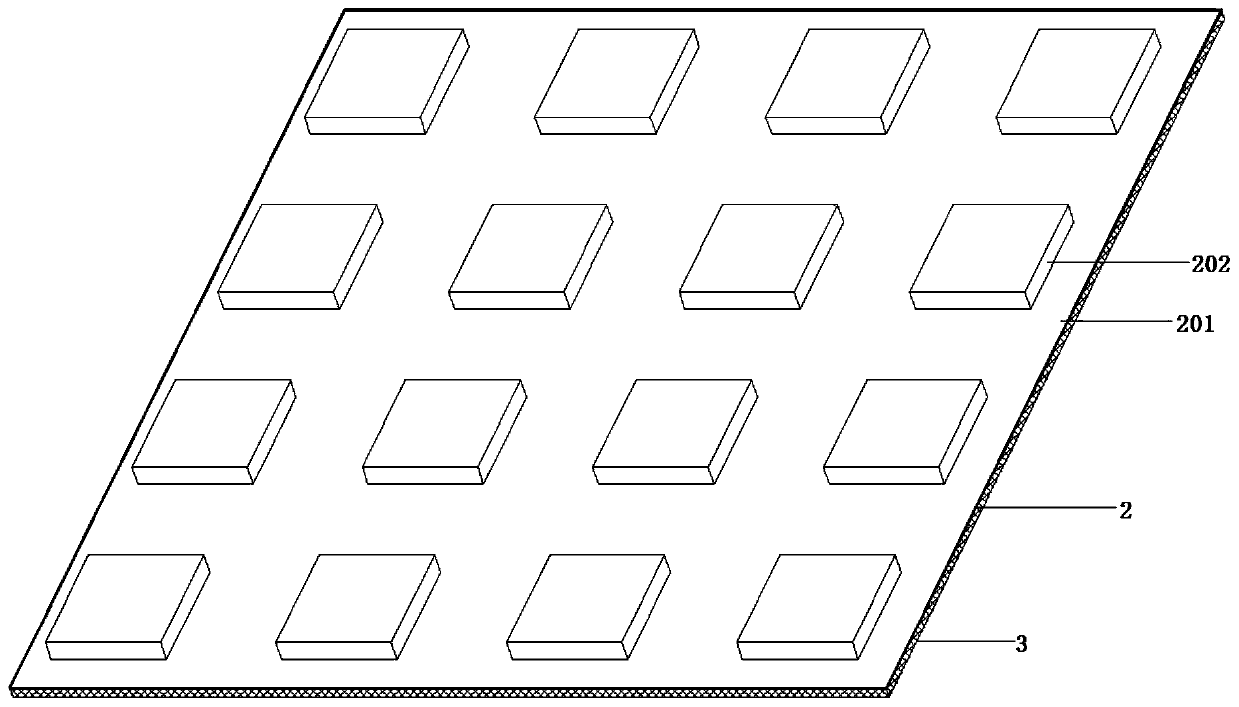

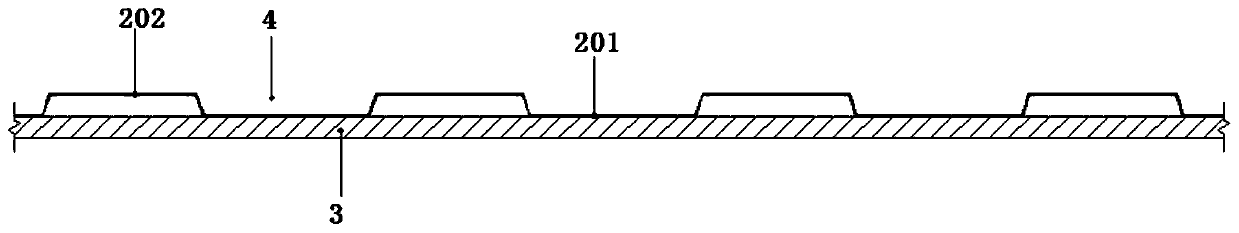

[0057] Such as figure 1 and figure 2 The composite drainage board 1 shown includes a bottom layer 3 and a surface layer 2 . The surface layer 2 is made of high-density polyethylene material and has waterproof properties. The surface layer 2 includes a surface layer body 201 and several convex bodies 202 arranged in a matrix and arranged on the surface layer body 201 . The convex body 202 is a square convex body with a large surface area, and the surface of the convex body 202 is a rough surface, which is easy to retain the viscous slurry material, which is convenient for sticking and fixing, and the construction and paving is less difficult. The space formed between the convex body 202 and the convex body 202 is the drainage channel 4 . The row pitch and the row pitch between the protrusions 202 are equal. Below the surface layer 2 is the bottom layer 3, and the bottom layer 3 is a polyethylene elastic layer, which has the effect of coordinating deformation and flame reta...

Embodiment 2

[0060] In this embodiment, the structure of the composite drainage board is similar to that of Embodiment 1. The height of the composite drainage board is 10-15 mm, the surface layer is 5-10 mm high, the plate thickness is 1-2 mm, and the convex body is a square with a side length of 30 mm. 3mm ~ 9mm, row spacing and row spacing are equal, both are 30mm. The bottom layer is 5mm high.

Embodiment 3

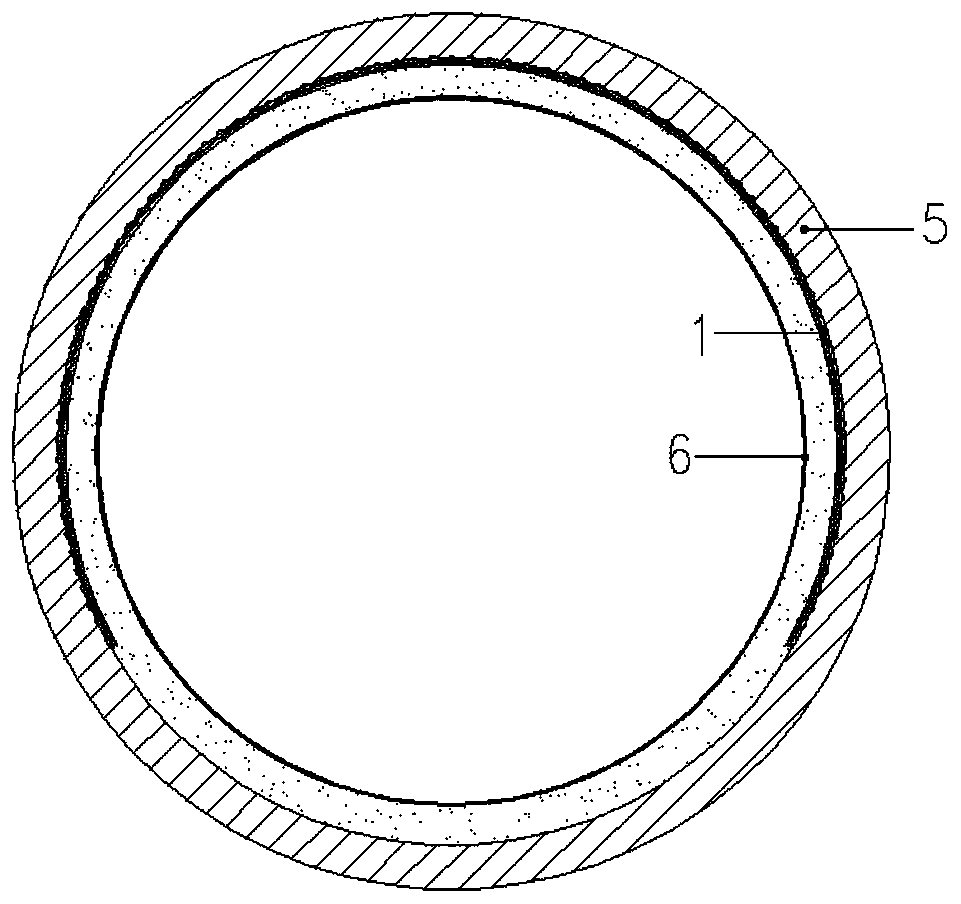

[0062] In this embodiment, it is designed based on the design method of the above-mentioned composite drainage board. Similar to Embodiment 2, the thickness of the surface layer is 1.0mm to 1.5mm (the penetration strength of the surface layer body with a thickness of 1.0mm is not less than 300N, and the thickness of the surface layer is 1.5mm. The puncture strength of the surface layer body is not less than 350N, and the puncture resistance is much greater than that of PE film), the surface layer drainage channel height (convex body height) of the composite drainage board is 8.5mm, and the drainage channel width (convex body row spacing) is 25mm ( The waterproof level of the tunnel is level two, the outer diameter of the tunnel is 6.0m, and the length of the tunnel is 3000m. After calculation, the total seepage of the tunnel is about 2828L / d, the drainage safety factor Fs is greater than 5, and the height and width of the drainage channel can meet the drainage capacity requireme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com