Tube-in-tube bridge tower of space hybrid cable net suspension bridge with parabolic arched tower cap

A space-mixing, tube-in-tube technology, applied to suspension bridges, bridges, bridge parts, etc., can solve the problems of not being able to meet the wind resistance stability requirements, lateral stiffness and torsional stiffness of 4,000-meter-class super-long-span suspension bridges across the Strait, etc. Achieve the effect of increasing the critical wind speed of flutter, improving the anti-seismic performance, and ensuring the stability of wind resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

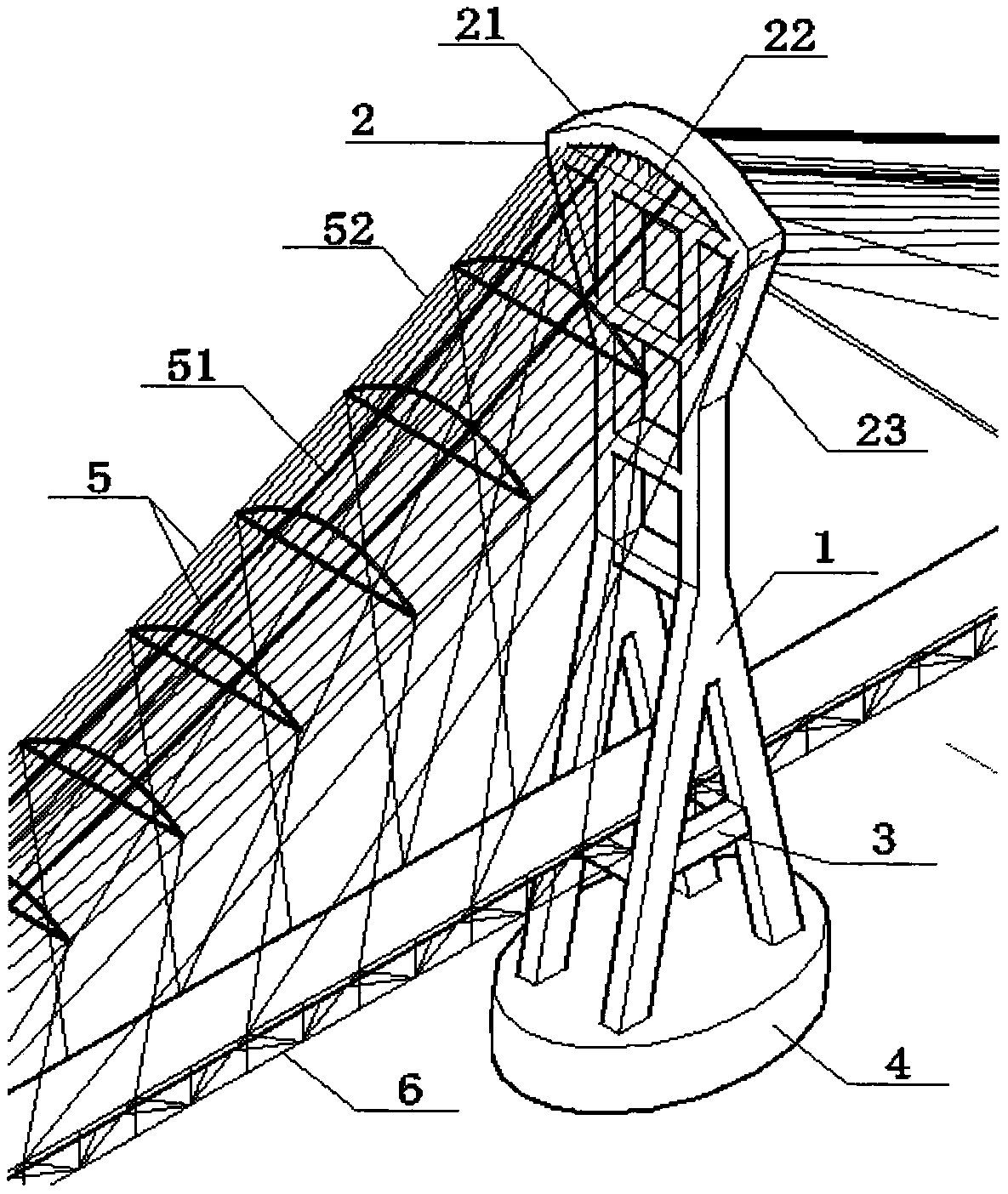

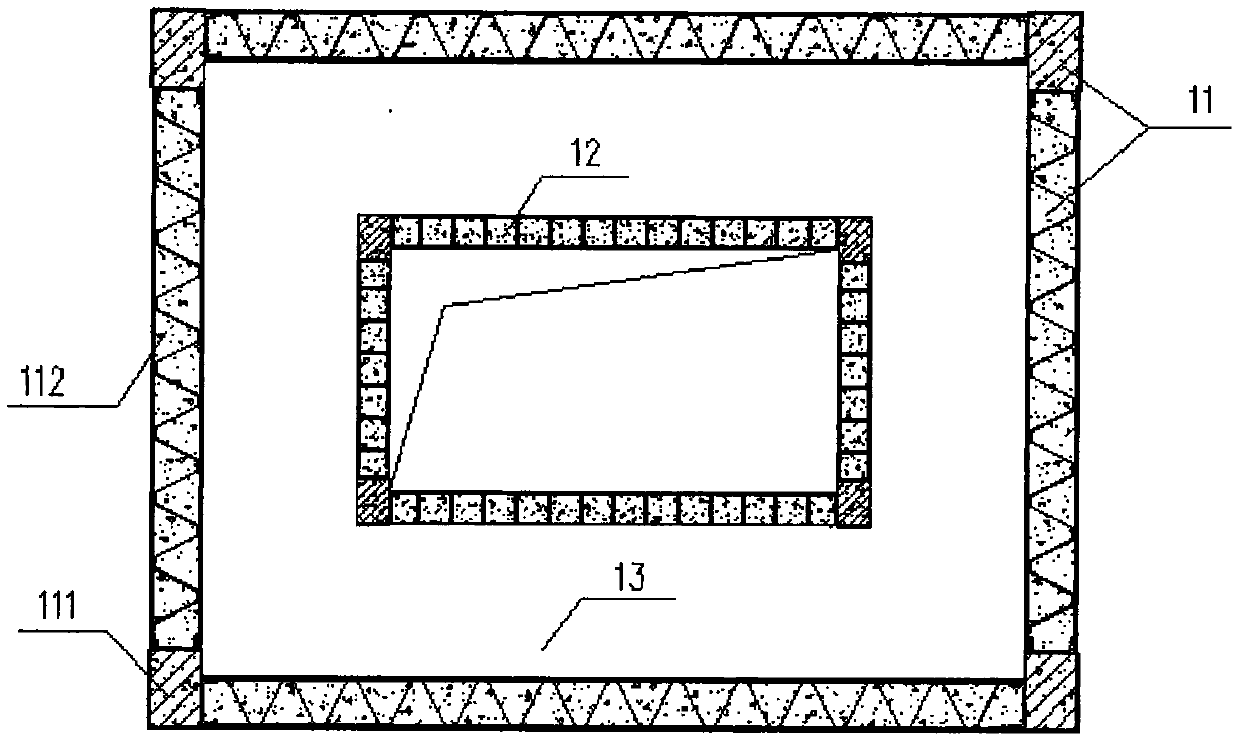

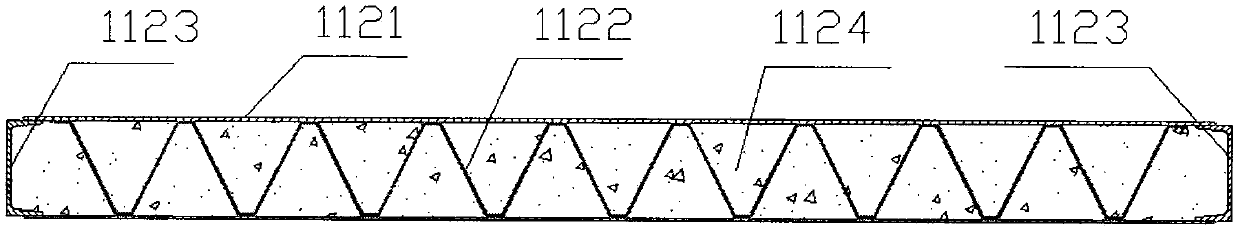

[0034] A tube-in-tube bridge tower of a space hybrid cable-net suspension bridge with a parabolic arched tower cap of the present invention includes a tube-in-tube herringbone tower column 1 and a parabolic arched tower cap 2, and the tube-in-tube herringbone tower column 1 Composed of an outer tube structure 11, a core tube structure 12 and several rigid diaphragms 13, a tube-in-tube herringbone column 1 is arranged on the left and right sides of the suspension bridge tower, and the parabolic arched tower cap 2 is composed of a giant Parabolic arch 21, giant rigid tie rod 22 and giant diagonal brace 23 are composed of three. The giant parabolic arch 21 is placed on two tube-in-tube herringbone towers 1 in the way of cantilever at both ends. The end arch feet are connected by a huge rigid tie rod 22, one end of the giant diagonal brace 23 is an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com