Formwork Supporting Device for Concrete Support Construction of Well Roadway Engineering

A concrete and engineering technology, applied in shaft equipment, shaft lining, earthwork drilling, etc., can solve the problems of traffic, construction inconvenience, production and installation cost, and wood consumption, etc., to improve labor productivity, stable and firm structure, and economical effect of wood

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with embodiment the present invention is described in further detail:

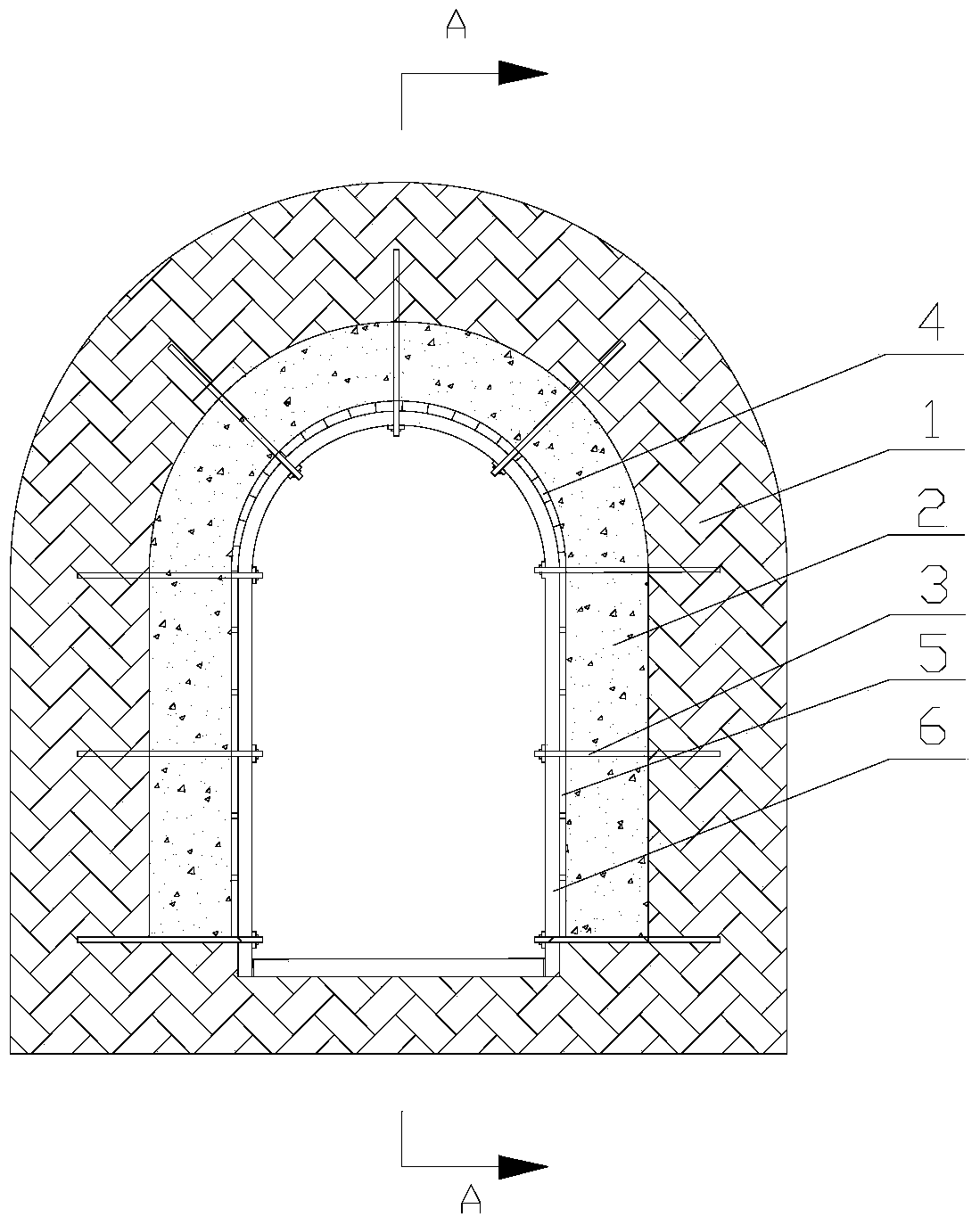

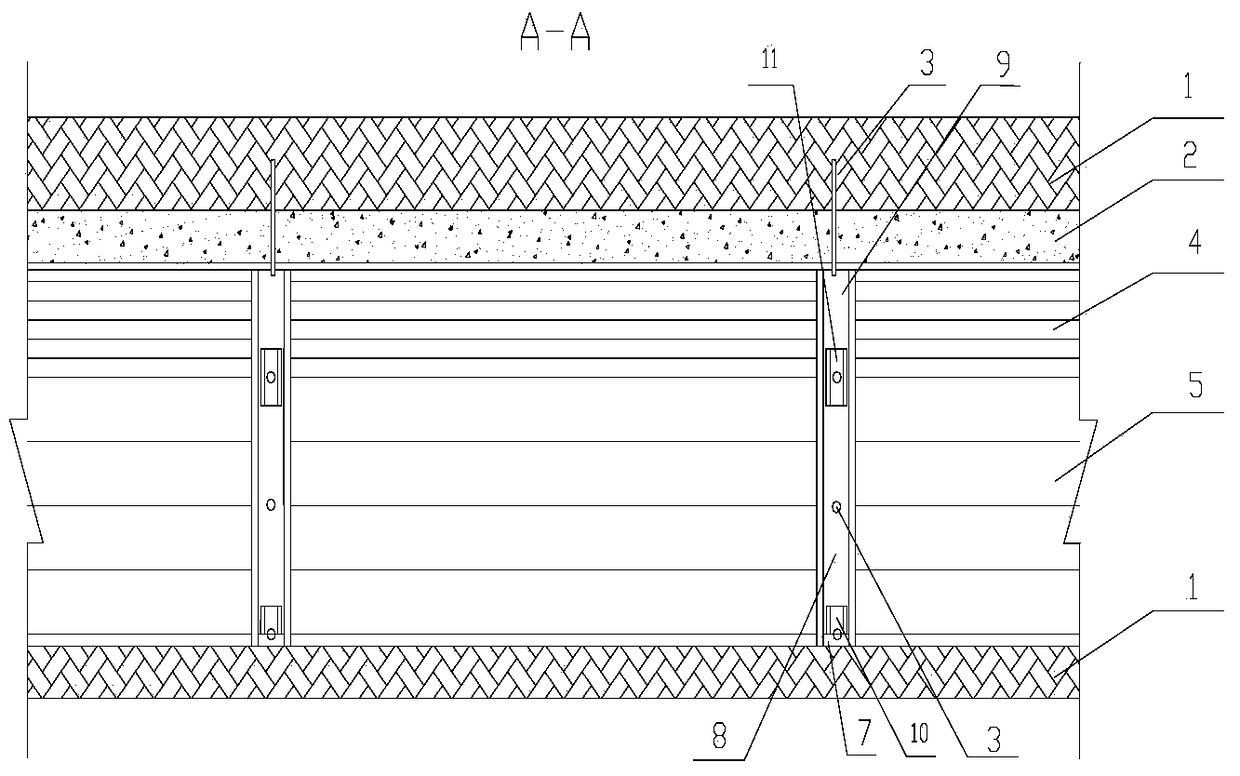

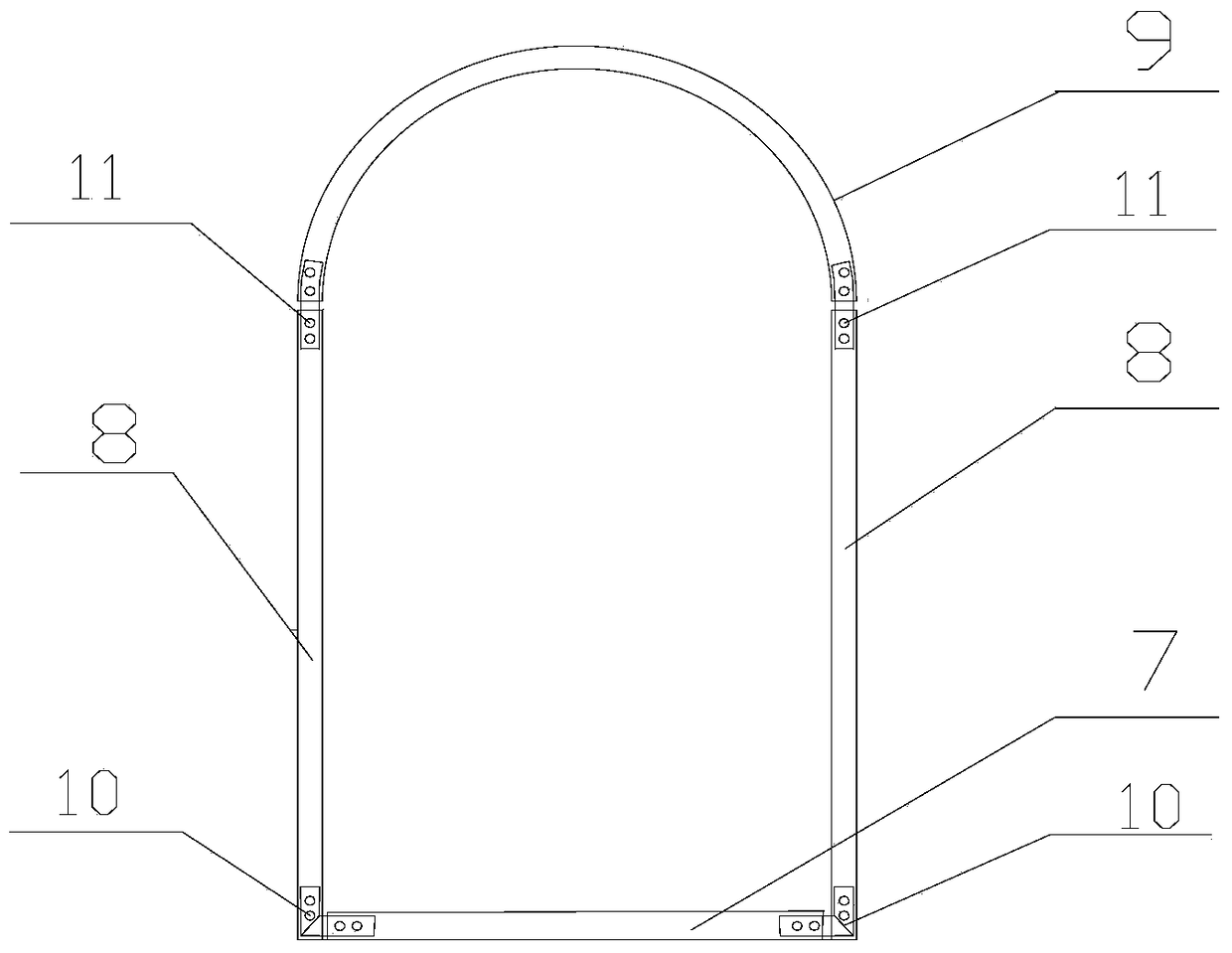

[0024] Depend on figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 It can be seen that the formwork device for the concrete support construction of the shaft engineering includes a wall formwork 5 and a vault formwork 4, and the formwork device is composed of a steel keel 6 and a fixed anchor rod 3; And the vault beam 9 is made of channel steel, and the cross brace, column and vault beam are connected by the wall bottom connector 10 and the wall top connector 11 to form a high-strength airtight steel keel; the fixed anchor rod is composed of a rod body 12, a cover plate 15 and nut 16; the steel keel is positioned on the rod body 12 by the cover plate and the nut, and the rod body is firmly fixed in the surrounding rock 1 by the anchoring agent 14 through the drill hole 13; Installed at intervals of 1500mm; the wall formwork and vault formwork are installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com