A prefabricated bridge structure

A bridge structure and assembly technology, applied in the direction of bridges, bridge construction, bridge parts, etc., can solve problems affecting the service life of bridges, and achieve the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

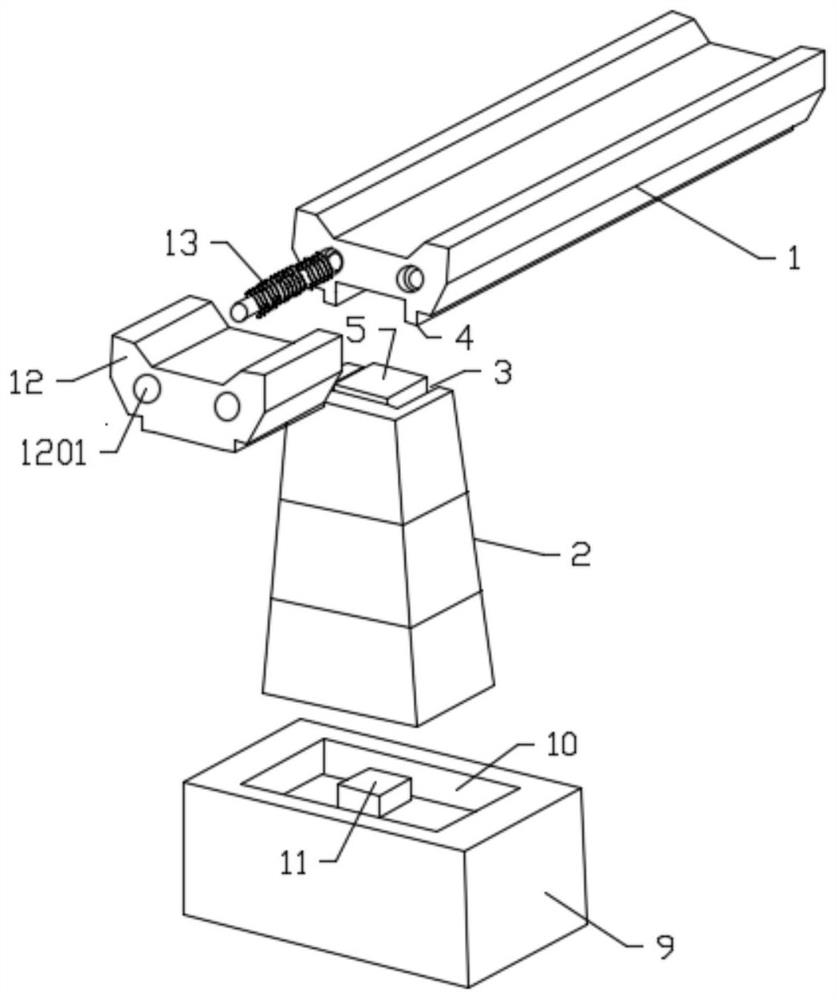

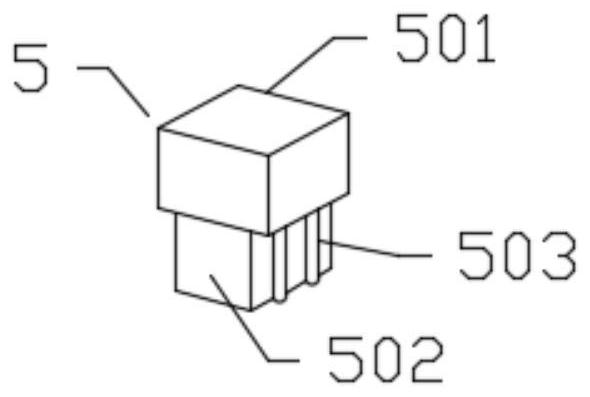

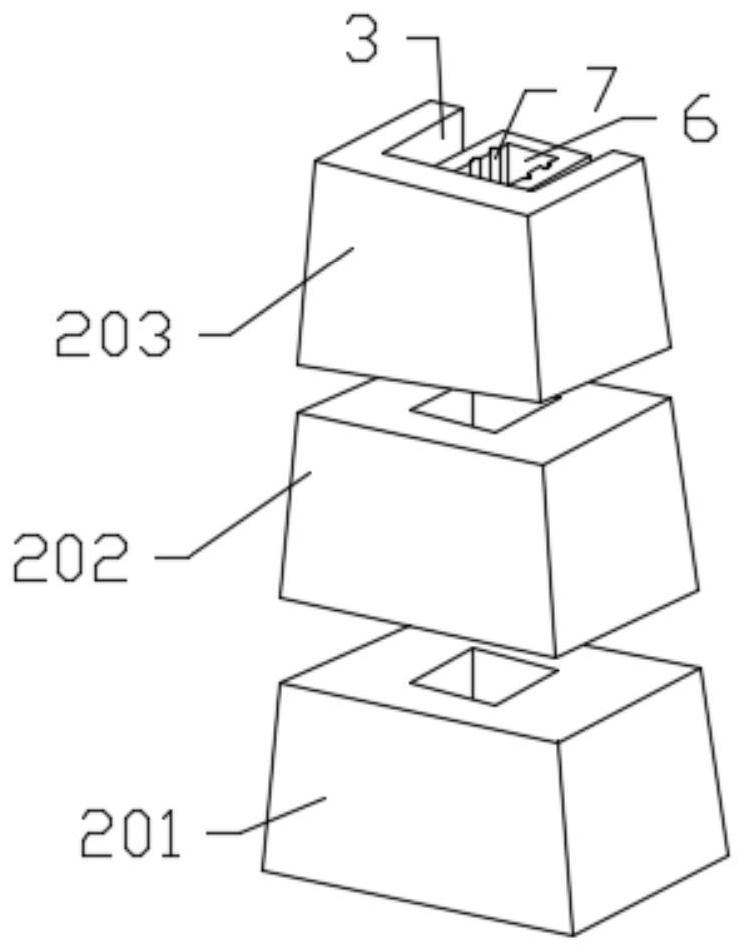

[0022] figure 1 2 is a structural schematic diagram of the support member, 3 is a three-dimensional schematic diagram of a bridge pier, 4 is a cross-sectional schematic diagram of a bridge pier, and 5 is a schematic diagram of a connecting piece. Invented a prefabricated bridge structure, including a main girder 1 and a pier 2 for supporting the main girder 1, on the upper end surface of the pier 2 along the longitudinal direction of the bridge is provided with a non-through chute 3, on the The bottoms of both ends of the main girder 1 are provided with ribs 4 corresponding to the chute 3, and the chute 3 and the rib 4 are slidingly fitted; The supporting member 5, the supporting member 5 is an elastic supporting member, the upper surface of the pier 2 is provided with a mounting groove 6 for installing the supporting member 5, the upper s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com