A kind of plastic film that can be used on the inner surface of lunch box and its preparation method

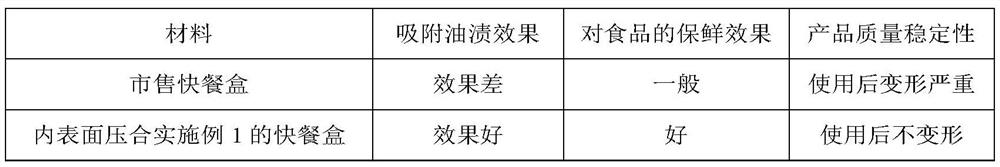

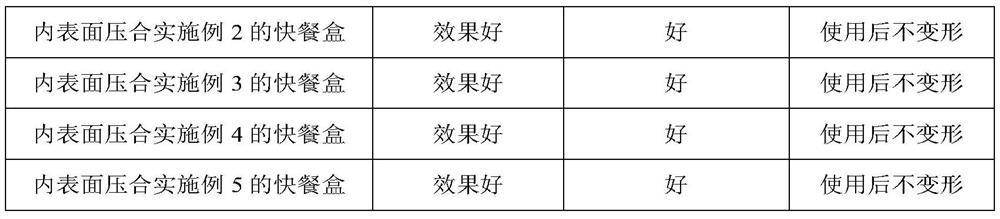

A technology of plastic film and inner surface, applied in the field of plastic film and its preparation, can solve the problems of unfavorable health of consumers, unstable structure of fast food boxes, poor oil absorption, etc., so as to ensure human health, avoid oil leakage, guarantee effect of freshness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A plastic film that can be used on the inner surface of the lunch box

[0030] The raw materials for preparing the upper and lower surface layers of the plastic film that can be used on the inner surface of the lunch box include: polyethylene 5000g, tea polyphenols 1000g, purple potato starch 200g, methyl paraben 100g, sodium carboxymethyl cellulose 200g; the raw materials of the plastic film intermediate layer that can be used on the inner surface of the lunch box include by weight: polyethylene 5000g, tea polyphenols 1000g, purple potato starch 200g, methyl paraben 100g, carboxymethyl fiber Plain sodium 200g, sawdust 100g.

[0031] Prepared by:

[0032] In step a, the weight portion of sodium carboxymethylcellulose is prepared into a solution with a viscosity of 300 mpa·s, the weight portion of purple potato starch is added, and the temperature is 60° C., sonicated for 1 hour to obtain a mixed solution;

[0033] Step b, adding the polyethylene, tea polyphenol, and m...

Embodiment 2

[0038] A plastic film that can be used on the inner surface of the lunch box

[0039]The raw materials for preparing the upper and lower surface layers of the plastic film that can be used on the inner surface of the lunch box include: polyethylene 6000g, tea polyphenols 1500g, purple potato starch 400g, methyl paraben 150g, carboxymethyl cellulose Sodium 400g; The raw material that can prepare the plastic film intermediate layer that can be used on the inner surface of the lunch box includes by weight: polyethylene 6000g, tea polyphenols 1500g, purple sweet potato starch 400g, methyl paraben 150g, carboxymethyl Sodium cellulose 400g, sawdust 200g.

[0040] Prepared by:

[0041] In step a, the weight portion of sodium carboxymethylcellulose is formulated into a solution with a viscosity of 500 mpa·s, the weight portion of purple potato starch is added, and the temperature is 65° C., sonicated for 2 hours to obtain a mixed solution;

[0042] Step b, adding the polyethylene, t...

Embodiment 3

[0047] A plastic film that can be used on the inner surface of the lunch box

[0048] The raw materials for preparing the upper and lower surface layers of the plastic film that can be used on the inner surface of the lunch box include: polyethylene 5200g, tea polyphenols 1300g, purple potato starch 260g, methyl paraben 120g, sodium carboxymethyl cellulose 260g; the raw materials for preparing the plastic film intermediate layer that can be used on the inner surface of the lunch box include by weight: polyethylene 5200g, tea polyphenols 1300g, purple potato starch 260g, methyl paraben 120g, carboxymethyl fiber Sodium 260g, sawdust 120g.

[0049] Prepared by:

[0050] In step a, the weight part of sodium carboxymethyl cellulose is prepared into a solution with a viscosity of 400 mpa·s, the weight part of purple potato starch is added, and the temperature is 62 ° C, ultrasonic for 1.2 h to obtain a mixed solution;

[0051] Step b, adding the polyethylene, tea polyphenol, and m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com