Special numerically-controlled milling machine for machining for television borders

A CNC milling machine and frame technology, applied in the field of mechanical processing, can solve the problems of high labor intensity, increase of enterprise cost, waste of manpower, etc., and achieve the effects of fast tool change, improved production efficiency, and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030]The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

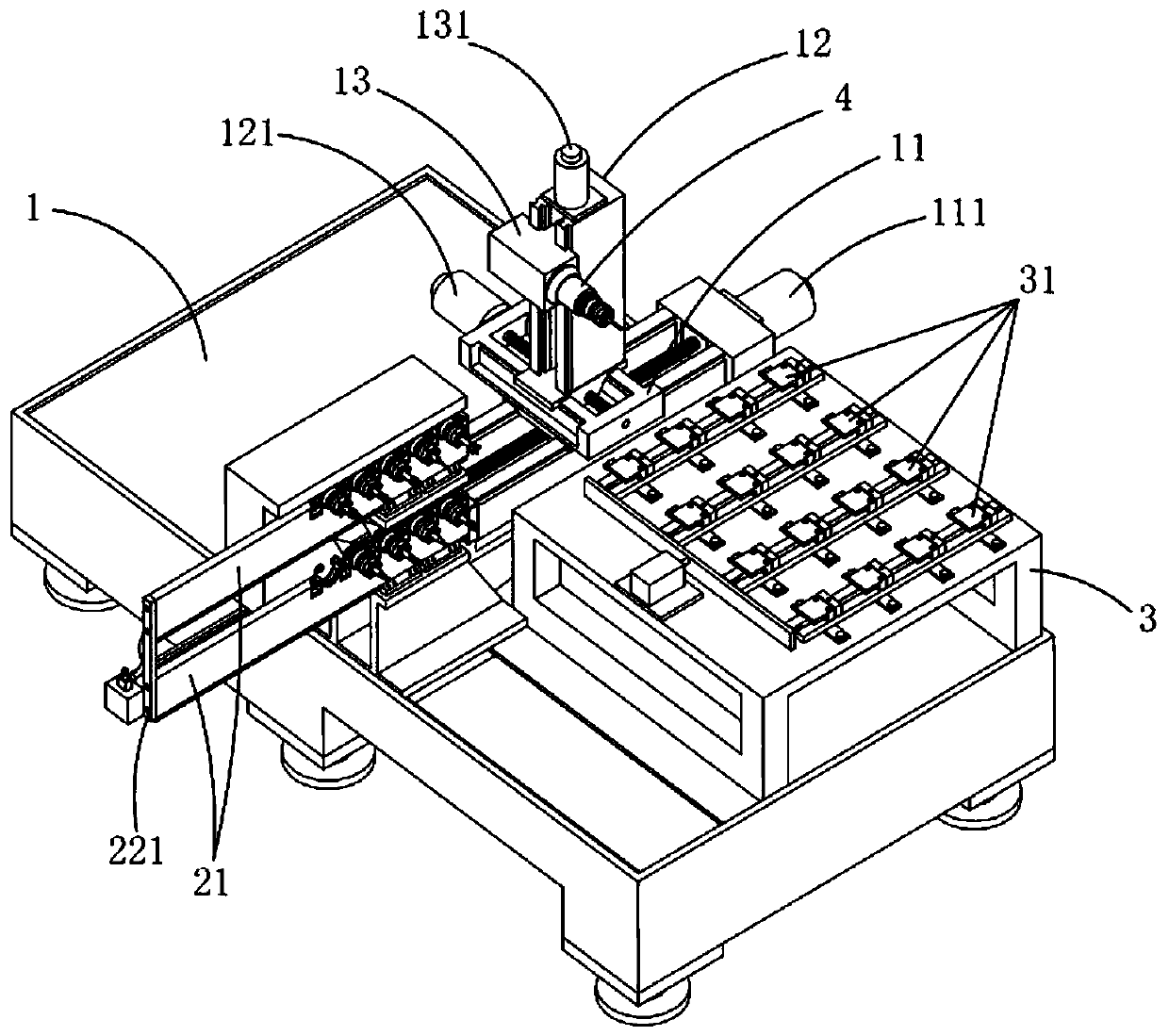

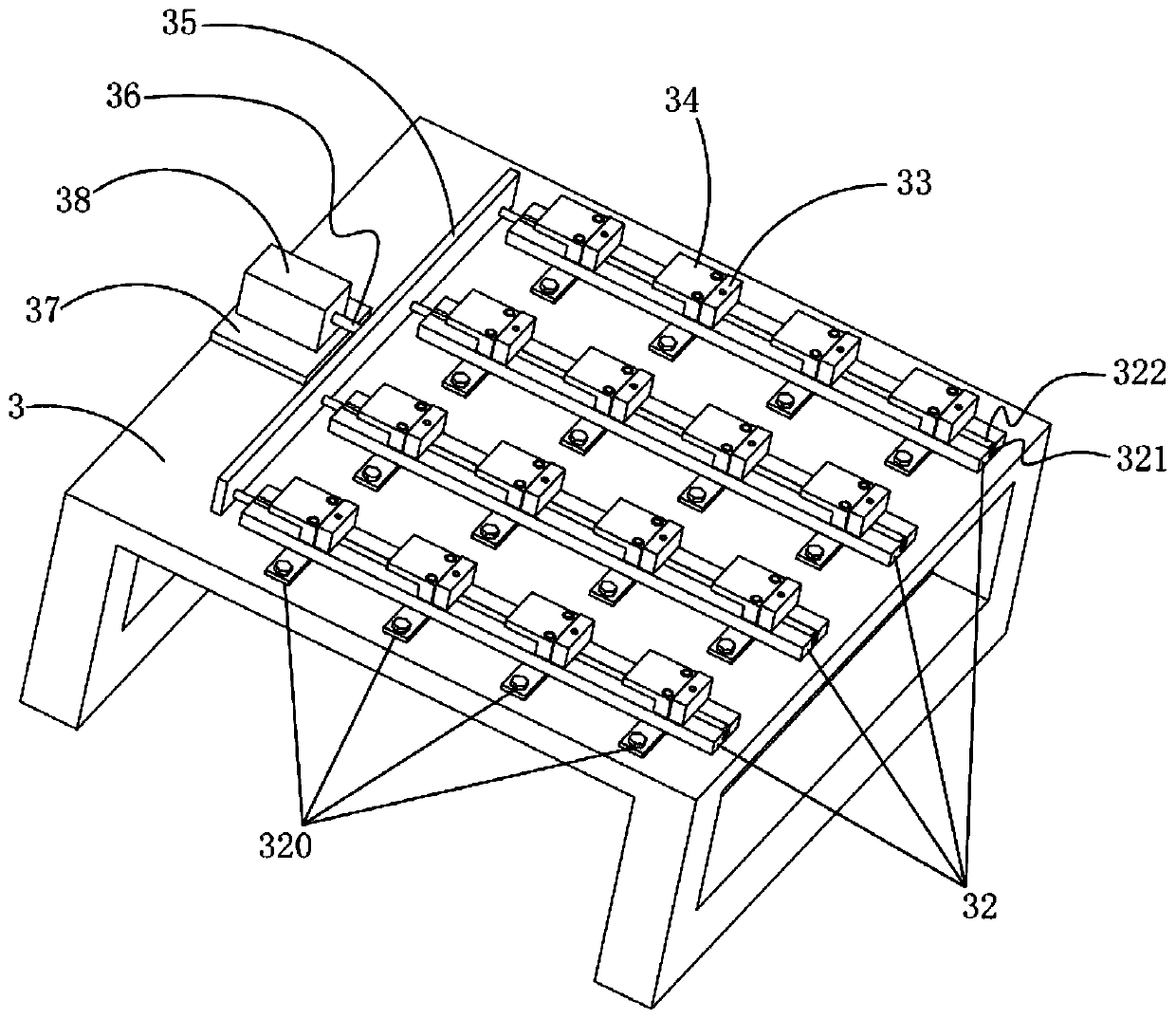

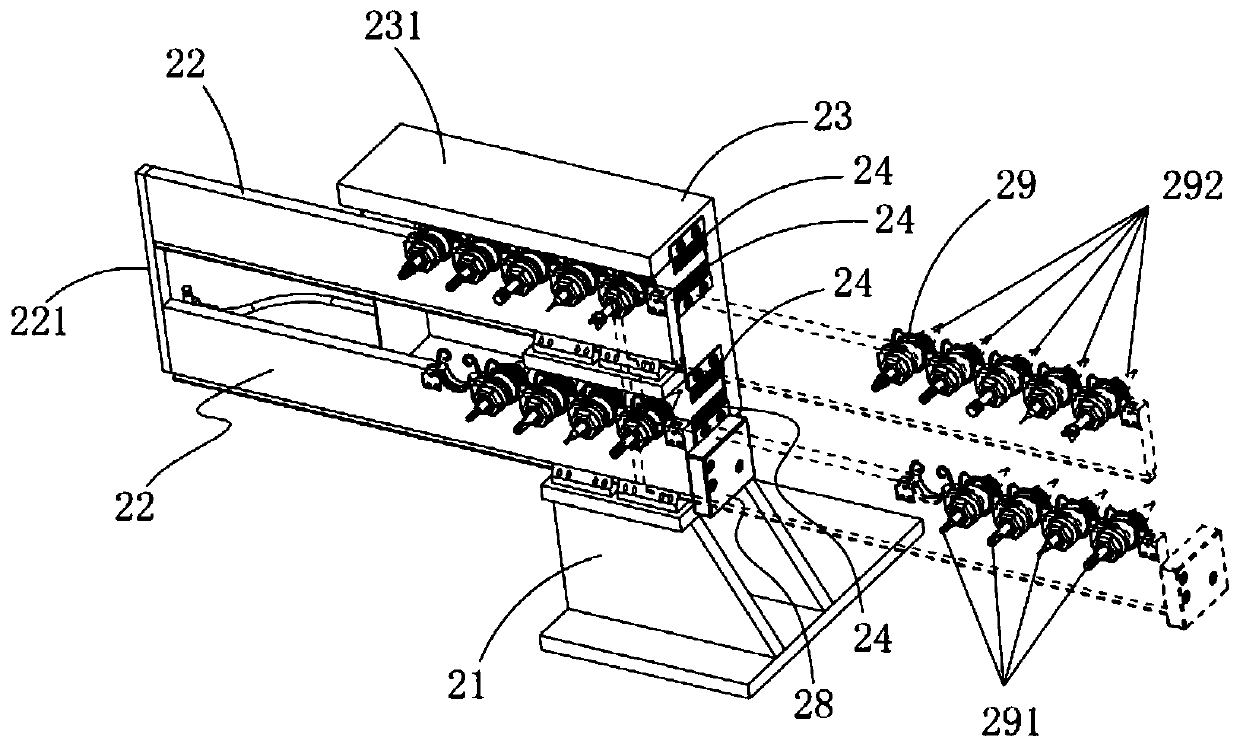

[0031] Examples, see Figure 1 to Figure 6 As shown, a CNC milling machine dedicated to processing TV frames, the CNC milling machine includes a machine base 1, a processing table 3 and a milling mechanism are arranged on the machine base 1, the milling mechanism is located on one side of the processing table 3, and the milling mechanism cooperates with the processing table 3 for milling , one side of the processing table 3 is set as a tooling side, at least one frame material to be processed is clamped on the table top of the processing table 3, each frame material is distributed along the tooling side at intervals, each frame material is parallel to each other, and each frame material is uniform Vertical tooling edge; milling mechanism is located at the corresponding side of tooling edge, and milling mechanism i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com