An electromagnetic type ultra-thin-wall pipe multi-diameter segmental bending forming device

A bending forming and ultra-thin-walled technology, which is applied in the cold processing of metal materials and engineering materials processing and forming, can solve the problems of the applicability of heavy bending pipe forming mechanisms, the inability to change the bending angle, and poor processing quality of thin-walled pipes, so as to avoid Cracks on the outside and excessive accumulation or wrinkling on the inside, the effect of improving processing, and the effect of avoiding processing defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below with reference to the drawings and embodiments.

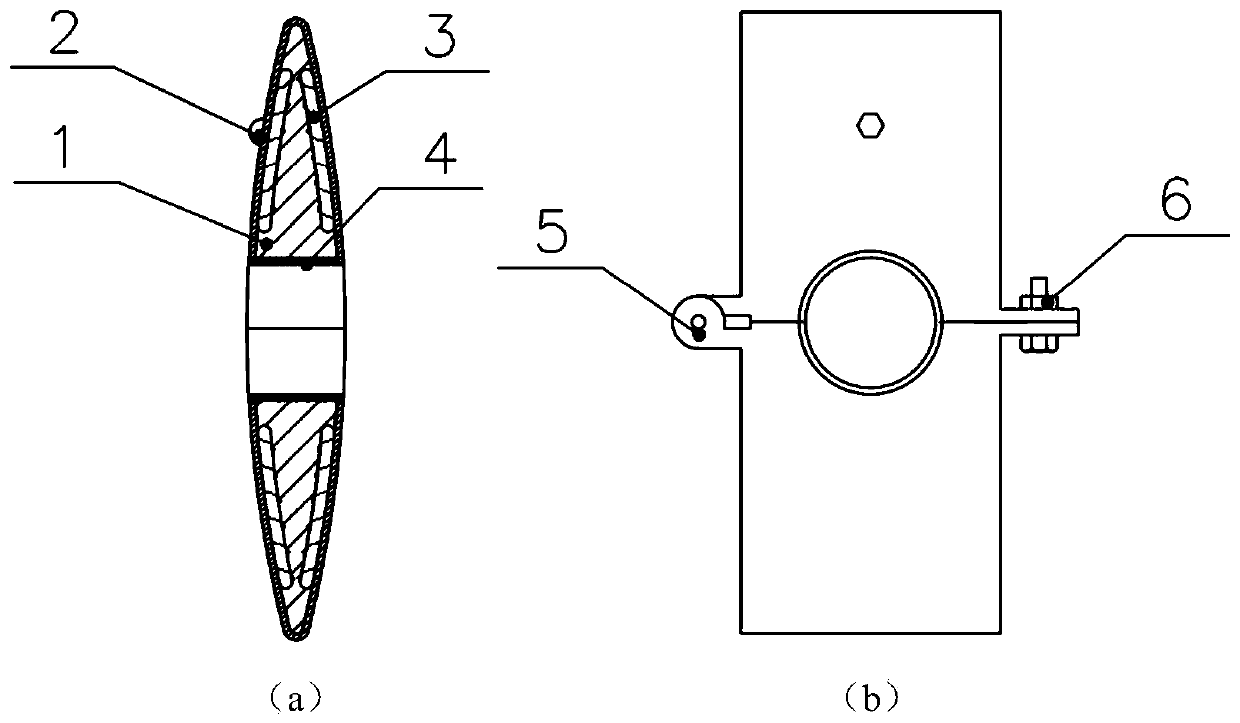

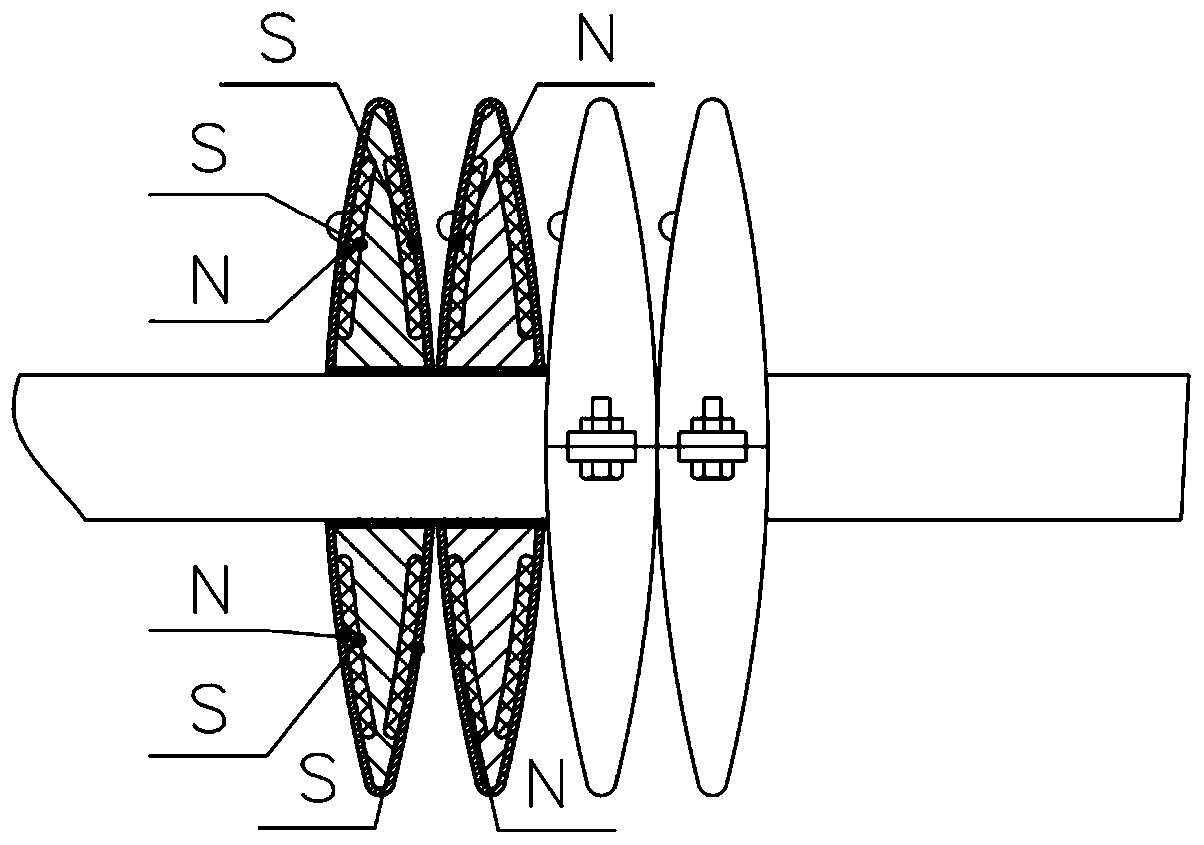

[0025] Such as figure 1 As shown in (a), the specific implementation of the present invention includes a plurality of basic unit bodies with the same structure set on a pipe. Each basic unit body is mainly composed of a base 1, a limiting protrusion 2 and an electromagnet 3. The base 1 is divided into The two sub-bases of the two parts are in a spindle shape after being butted, so that the two sub-bases face arc surfaces on both sides of the pipe axis. Each sub-base is in the shape of a half spindle. Outside the pipe, the base 1 viewed along the axial direction of the pipe has a square shape, and the base 1 viewed along the radial side of the pipe has a spindle shape, and its shape is derived from a round bisected spindle. The base body 1 has an arc-shaped outer surface, which is obtained by making a spindle-shaped circular bisector.

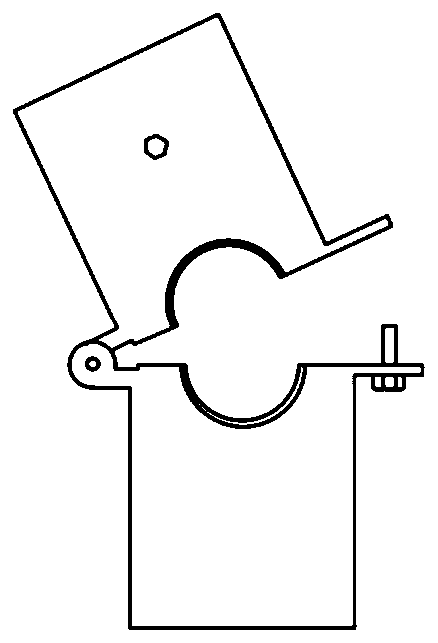

[0026] Such as figure 1 (b) and fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com