A kind of fluorite flotation collector and its preparation method and application

A collector and flotation technology, used in flotation, solid separation, etc., can solve the problem that the flotation collector is not suitable for the flotation of various minerals, the selectivity of the carboxylic acid collector is poor, and the recovery rate of fluorite flotation It can achieve the effect of improving secondary enrichment, good water-soluble dispersibility and flotation selectivity, and stable flotation index.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

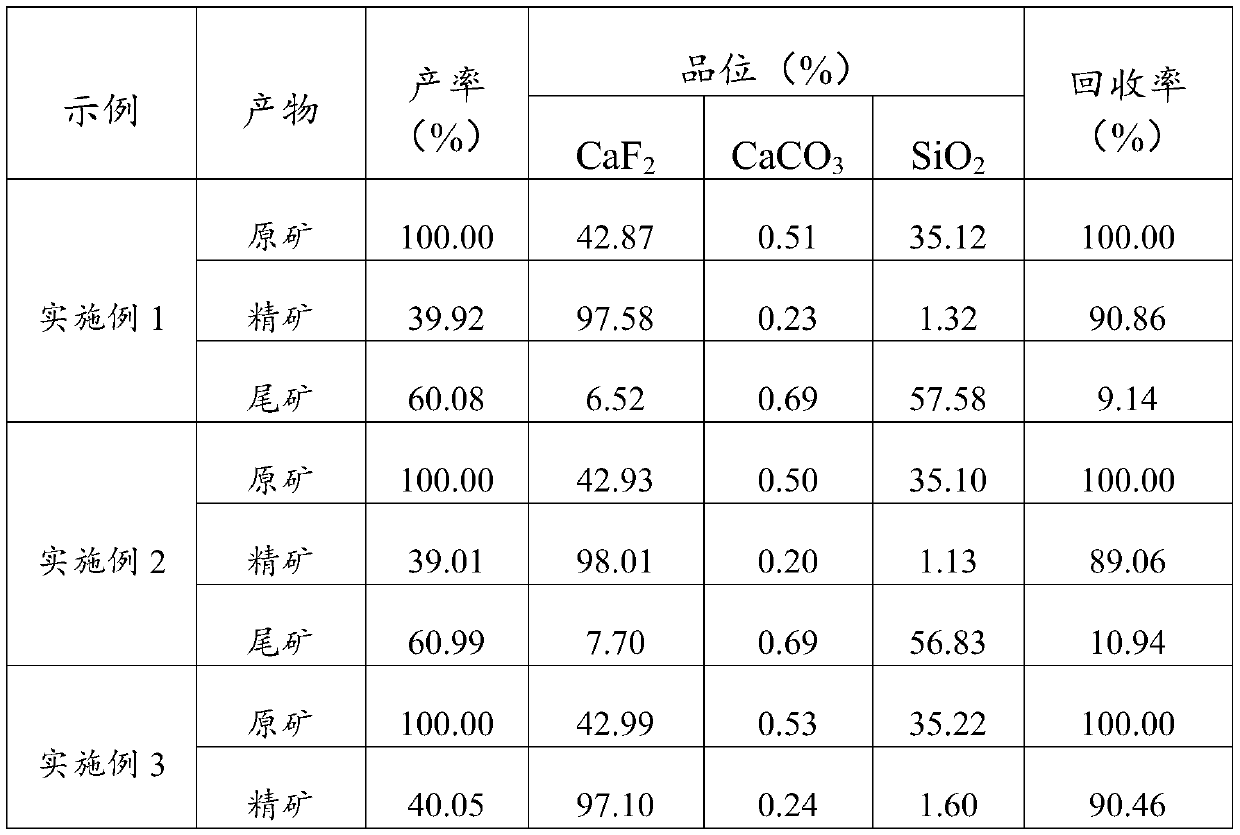

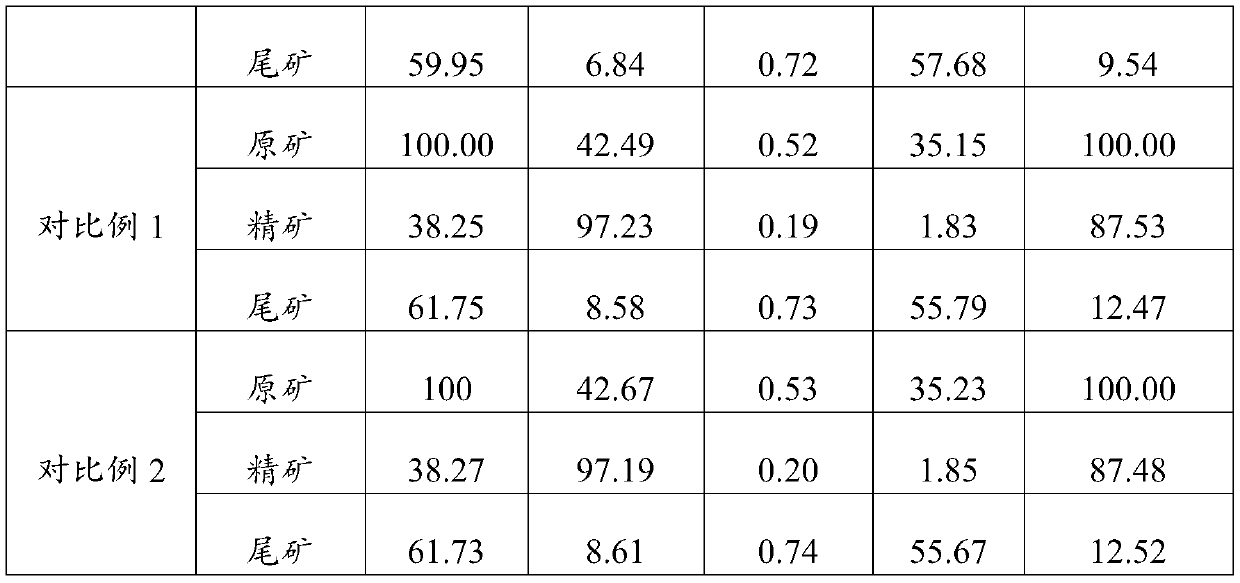

Embodiment 1

[0027] This embodiment provides a kind of flotation collector and its preparation method and application, specifically,

[0028] Described flotation collector comprises the dioctyl sulfosuccinate disodium, oleic acid and ethanol that quality is 143kg, 778kg and 79kg;

[0029] The preparation method of above-mentioned flotation collector is:

[0030] sequentially add oleic acid, dioctyl sulfosuccinate disodium and ethanol into the reaction kettle, stir thoroughly for 1 hour to obtain the collector;

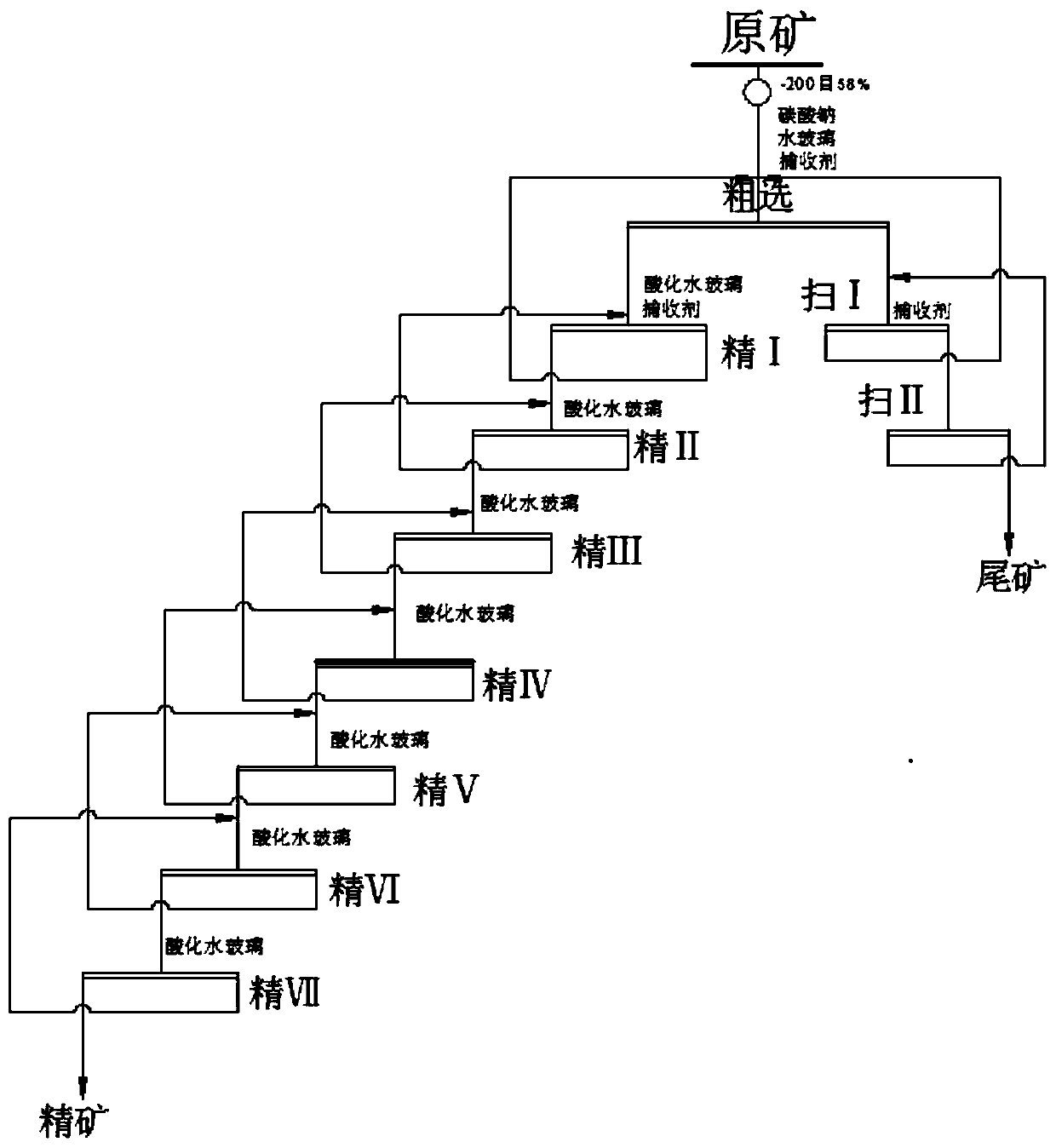

[0031] see figure 1 , which is a process flow diagram for the application of collectors provided by the invention in fluorite flotation, and the specific steps are as follows:

[0032] Rough separation: Grinding 1000kg of raw ore to obtain a grinding product, the content of -200 mesh in the grinding product is 58%; adding 800g of regulator sodium carbonate, 800g of inhibitor water glass, and 1000g of collector to the grinding product Rough separation to obtain rough concentrate ...

Embodiment 2

[0036] This embodiment provides a kind of flotation collector and its preparation method and application, specifically,

[0037] Described flotation collector comprises the dioctyl sulfosuccinate disodium, oleic acid and ethanol that quality is 135kg, 760kg and 85kg;

[0038] The preparation method of above-mentioned flotation collector is:

[0039] sequentially add oleic acid, dioctyl sulfosuccinate disodium and ethanol into the reaction kettle, stir thoroughly for 1 hour to obtain the collector;

[0040] The application of the above flotation collectors in fluorite flotation is:

[0041] Rough separation: Grinding 1000kg raw ore to obtain a grinding product, the content of -200 mesh in the grinding product is 58%; adding 1200g regulator sodium carbonate, 400g inhibitor water glass, and 800g collector to the grinding product Rough separation to obtain rough concentrate and rough tailings;

[0042] Beneficiation: 7 times of beneficiation, adding collector and acidified wate...

Embodiment 3

[0045] This embodiment provides a kind of flotation collector and its preparation method and application, specifically,

[0046] Described flotation collector comprises the dioctyl sodium sulfosuccinate, oleic acid and ethanol that quality is 155kg, 790kg and 65kg;

[0047] The preparation method of above-mentioned flotation collector is:

[0048] Add oleic acid, dioctyl sodium sulfosuccinate and ethanol to the reaction kettle in turn, and stir thoroughly for 1 hour to obtain the collector;

[0049] The application of the above flotation collectors in fluorite flotation is:

[0050] Rough separation: Grinding 1000kg raw ore to obtain a grinding product, the content of -200 mesh in the grinding product is 58%; add 1000g regulator sodium carbonate, 600g inhibitor water glass, and 1500g collector to the grinding product Rough separation to obtain rough concentrate and rough tailings;

[0051] Beneficiation: 7 times of beneficiation, adding collector and acidified water glass dur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com