Method of taking wastes as carbon source to prepare carbon doped titanium oxide visible light catalyst

A titanium oxide, waste technology, applied in physical/chemical process catalysts, chemical instruments and methods, water pollutants, etc., can solve problems such as catalyst waste, achieve good dispersion, low temperature, and achieve the effect of double pollution control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

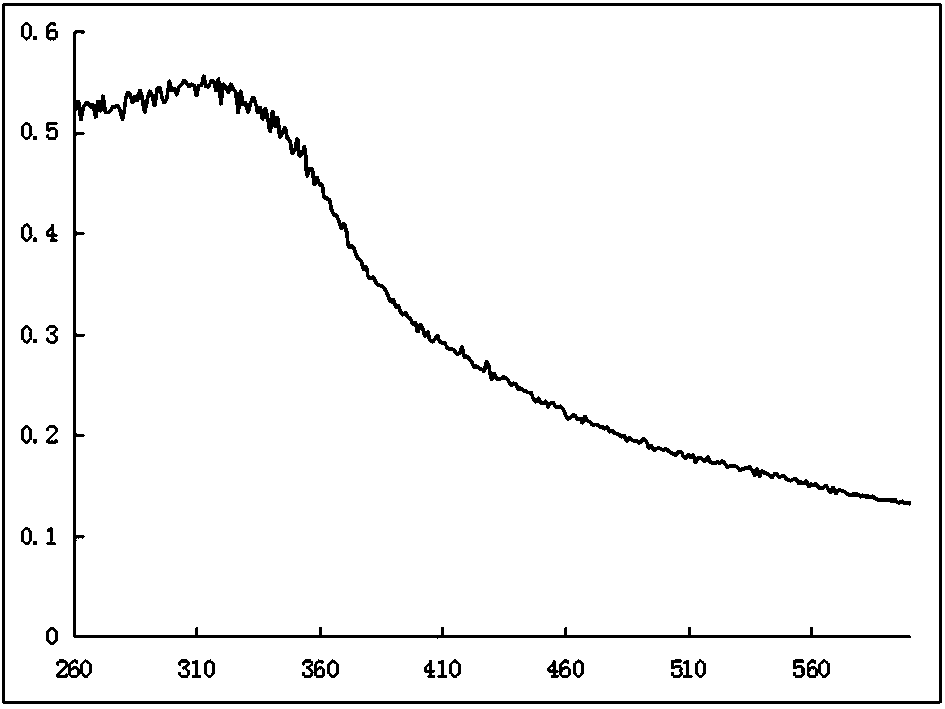

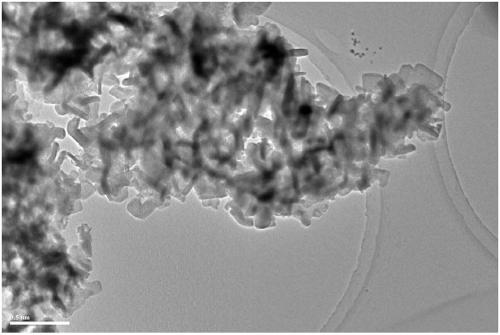

Image

Examples

preparation example Construction

[0037] 1) Preparation of carbon precursor-titanate melt: mix anhydrous sodium hydroxide and anhydrous potassium hydroxide, and melt at 180 ℃ ± 2 ℃, 0.1 MPa for 60 min ± 2 min to prepare the mixed Alkali clarification solution; fern leaf powder and titanium dioxide powder are added to the mixed alkali clarification solution, and stirred for 5-6 minutes to obtain fern leaf + sodium hydroxide + potassium hydroxide + titanium dioxide molten clarification solution; fern leaf + sodium hydroxide + hydroxide Potassium+titanium dioxide molten clarified solution was kept at 180 ℃±2 ℃ and 0.1 MPa for 720 min±10 min to obtain sodium hydroxide+potassium hydroxide+(NaOH 2 CO 3 +K 2 CO 3 )+carbon precursor-titanate melt;

[0038] 2) Add sodium hydroxide + potassium hydroxide + (Na 2 CO 3 +K 2 CO 3 )+carbon precursor-titanate melt, add a hydrochloric acid solution with pH=1, stir for 10 min, then naturally cool to room temperature, centrifuge, and take the off-white product in the lowe...

Embodiment 1

[0049] A method for preparing a carbon-doped titanium oxide visible light catalyst using waste as a carbon source, comprising the following steps:

[0050] 1) Preparation of carbon precursor-titanate melt: mix anhydrous sodium hydroxide and anhydrous potassium hydroxide, and melt at 180 °C and 0.1 MPa for 60 min to prepare a mixed alkali clarification solution; Add the leaf powder and titanium dioxide powder into the mixed alkali clarification liquid, stir for 5-6min, and obtain fern leaf + sodium hydroxide + potassium hydroxide + titanium dioxide molten liquid; put fern leaf + sodium hydroxide + potassium hydroxide + titanium dioxide molten liquid at 180 ℃, 0.1 MPa conditions for 720 min, to obtain sodium hydroxide + potassium hydroxide + (Na 2 CO 3 +K 2 CO 3 )+carbon precursor-titanate melt;

[0051] 2) Add sodium hydroxide + potassium hydroxide + (Na 2 CO 3 +K 2 CO 3 )+carbon precursor-titanate melt, add a hydrochloric acid solution with pH=1, stir for 10 min, then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com