Layered porous nitrogen-doped carbon material as well as preparation method and application thereof

A technology of nitrogen-doped carbon and hydrothermal reaction, applied in separation methods, sulfur preparation/purification, chemical instruments and methods, etc., can solve the problems of poor selectivity, easy deactivation, small specific surface area, etc., to improve activity and Stability, high structural stability, large surface area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

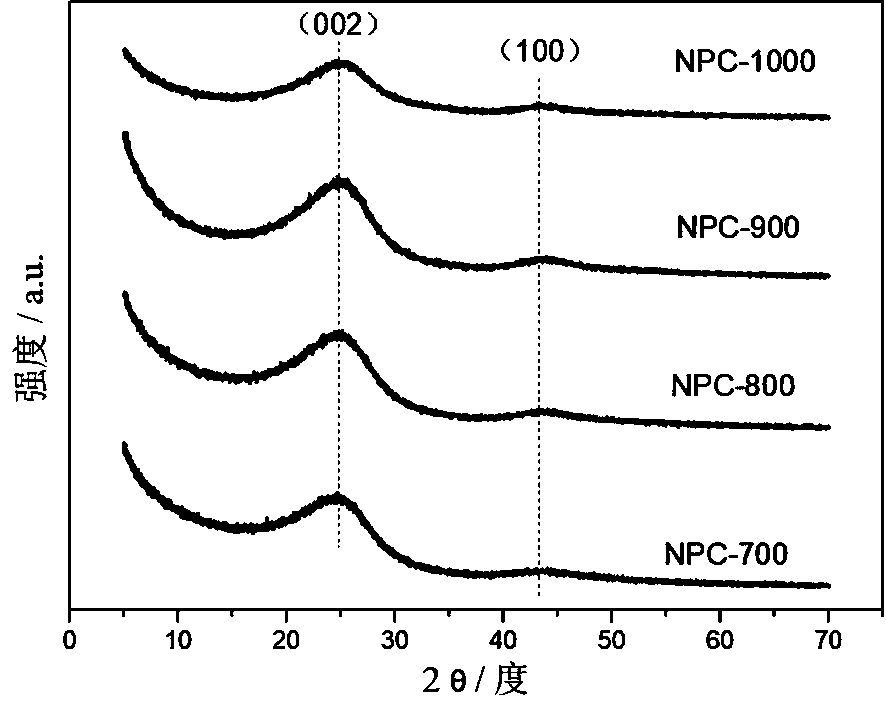

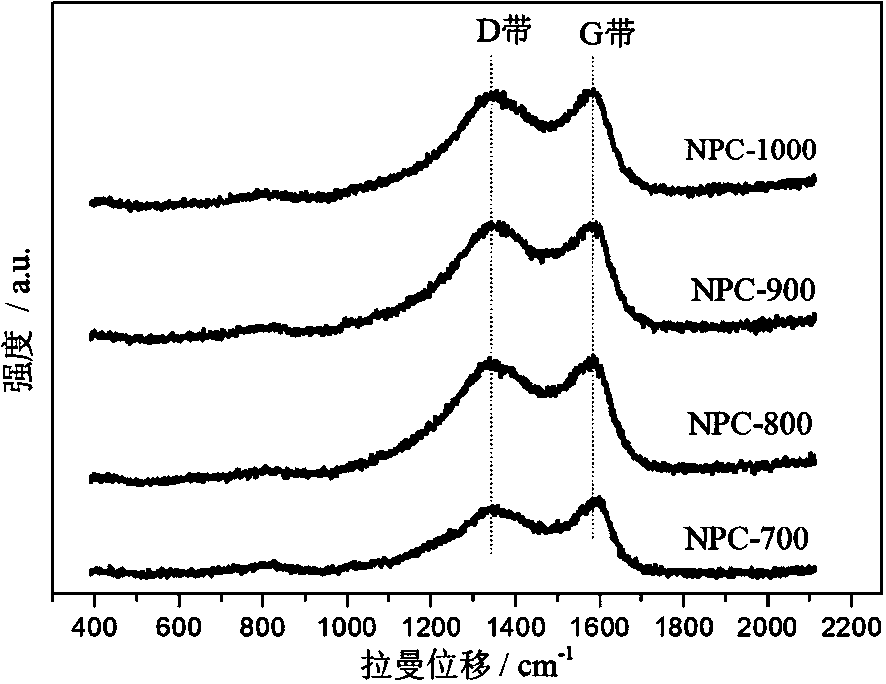

Embodiment 1

[0034] Add 0.01 mol of ethylenediamine to 60 ml of N,N-dimethylformamide, then add 0.01 mol of pyromellitic dianhydride, stir at room temperature for 10 h to a transparent solution, heat at 180 °C for 12 h, centrifuge, and use DMF and ethanol were washed, dried at 80 °C, the dried samples were ground and placed in a tube furnace device. After room temperature, the synthesized samples were collected and labeled NPC-700.

Embodiment 2

[0036] Add 0.01 mol of ethylenediamine to 60 ml of N,N-dimethylformamide, then add 0.01 mol of pyromellitic dianhydride, stir at room temperature for 10 h to a transparent solution, heat at 180 °C for 12 h, centrifuge, and use DMF and ethanol were washed, dried at 80 °C, the dried samples were ground and placed in a tube furnace device. After room temperature, the synthesized samples were collected and labeled NPC-800.

Embodiment 3

[0038] Add 0.01 mol of ethylenediamine to 60 ml of N,N-dimethylformamide, then add 0.01 mol of pyromellitic dianhydride, stir at room temperature for 10 h to a transparent solution, heat at 180 °C for 12 h, centrifuge, and use Washed with DMF and ethanol, dried at 80 °C, the dried samples were ground and placed in a tube furnace. After room temperature, the synthesized samples were collected and labeled NPC-900.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com