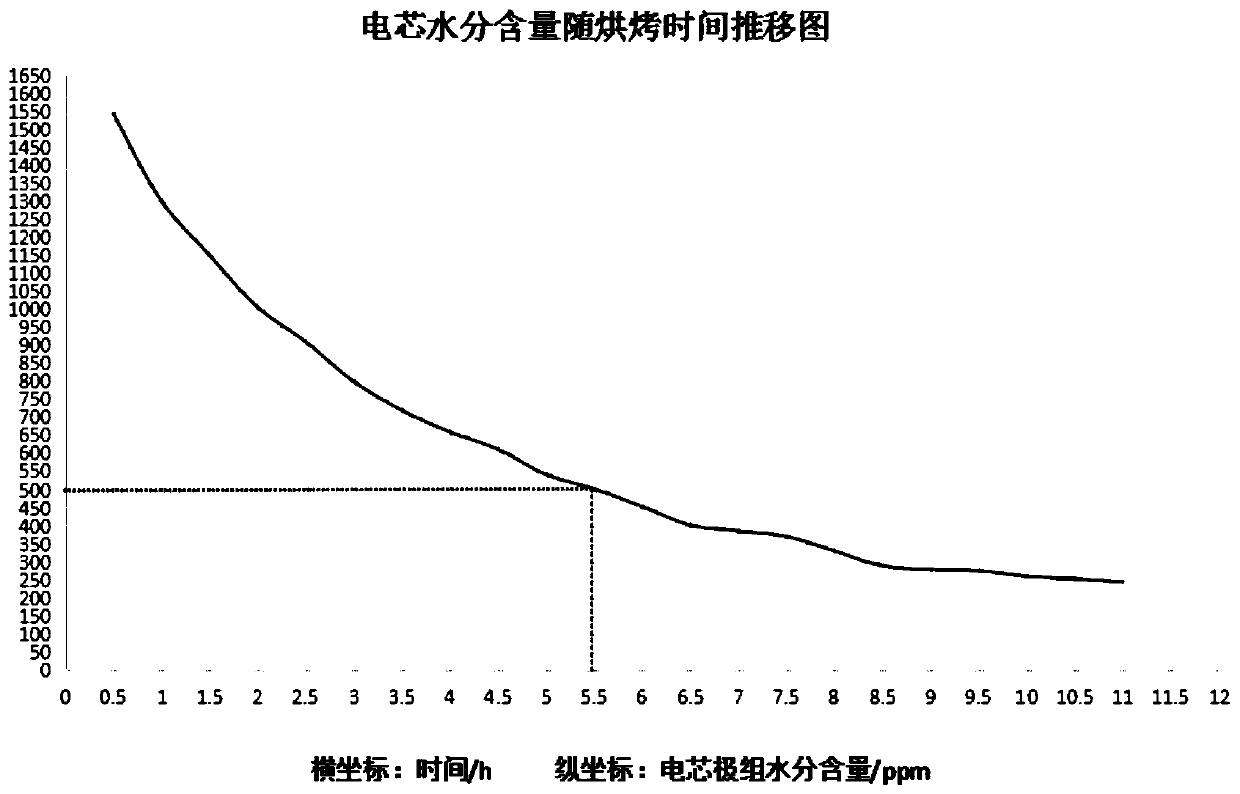

Staged baking process for water content in pole group of lithium ion battery

A lithium-ion battery and baking process technology, which is applied in electrode manufacturing, secondary batteries, circuits, etc., can solve the problems of single battery baking mode, low battery baking efficiency, and high moisture content in pole pieces. Baking time is shortened, cost output is reduced, and baking efficiency is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The present invention proposes a lithium-ion battery pole group moisture staged baking process, comprising the following steps:

[0025] S1. Put a total of 1008 LFP20100140-30AH square lithium-ion battery cells on a 4-layer baking tray into the oven, close the oven door; PLC controls the ceramic heating plate in the oven to start heating, and at the same time controls the vacuum pump to transfer the air in the oven Extraction, the temperature and pressure values in the oven are detected by the sensor in real time, and the data is transmitted to the PLC;

[0026] S2. After the oven is evacuated to a vacuum of 150Pa and the temperature is heated to 95°C, heat-preserve and pressurize and bake for 15 minutes, fill in nitrogen heated to 95°C to adjust the pressure to normal pressure, and keep the temperature at 95°C and bake for 15 minutes;

[0027] S3, repeating the operation of S2 10 times;

[0028] S4. Vacuum the oven to 200Pa, keep the temperature at 95°C, bake for 30...

Embodiment 2

[0034] The present invention proposes a lithium-ion battery pole group moisture staged baking process, comprising the following steps:

[0035] S1. Send the battery cells into the oven, and vacuumize the oven while heating;

[0036] S2. Adjust the temperature of the oven to 100°C and bake for 20 minutes at a vacuum of 100Pa, then pass in nitrogen to adjust the pressure to normal pressure, and bake at a temperature of 90°C for 20 minutes;

[0037] S3, repeating the operation of S2 8 times;

[0038] S4. Vacuum the oven to 200 Pa and keep the temperature of 90°C for 35 minutes, then pass nitrogen gas to adjust the pressure to normal pressure, and keep the temperature of 90°C for 20 minutes;

[0039] S5, repeating the operation of S4 5 times;

[0040] S6. After the oven is evacuated to 200Pa, the heating is stopped and cooled naturally.

Embodiment 3

[0042] The present invention proposes a lithium-ion battery pole group moisture staged baking process, comprising the following steps:

[0043] S1. Send the battery cells into the oven, and vacuumize the oven while heating;

[0044] S2. Adjust the temperature of the oven to 90°C and bake for 10 minutes at a vacuum of 200Pa, then pass in nitrogen to adjust the pressure to normal pressure, and bake at a temperature of 100°C for 10 minutes;

[0045] S3, repeating the operation of S2 12 times;

[0046] S4. Vacuum the oven to 100Pa and bake at a temperature of 100°C for 25 minutes, then pass nitrogen gas to adjust the pressure to normal pressure, and bake at a temperature of 100°C for 10 minutes;

[0047] S5, repeating the operation of S4 6 times;

[0048] S6. After the oven is evacuated to 100Pa, the heating is stopped and cooled naturally.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com