Fully compliant potassium ion battery capable of being charged and discharged as well as preparation method and application thereof

A potassium ion, fully flexible technology, used in electrolyte battery manufacturing, electrode manufacturing, secondary batteries, etc., can solve the problems of short life, poor rate, low energy density, etc., to improve rate performance and cycle stability, increase activity Site and interlayer spacing, the effect of improving specific surface area and interlayer spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

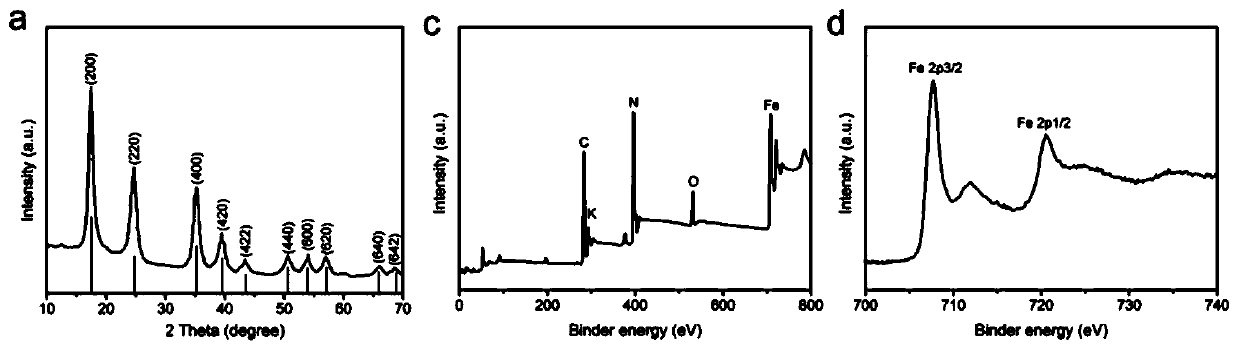

Image

Examples

Embodiment 1

[0052] Rechargeable fully flexible potassium ion battery, including positive electrode material, negative electrode material and electrolyte. Among them, the positive electrode material is KPB@CC nanomaterials, the negative electrode material is N,P-VG@CC nanomaterials, and the electrolyte is KPF 6 , ethylene carbonate, dimethyl carbonate and fluoroethylene carbonate mixed solution.

[0053] The preparation process of KPB@CC nanomaterials is as follows:

[0054] Prepare solution A: take 4mmol FeSO 4 ·H 2 O and 0.4g of PVP K-30 (ie, polyvinylpyrrolidone) were dissolved in 40ml of deionized water, stirred and mixed by a magnetic stirrer to obtain solution A.

[0055] Prepare solution B: take 4mmol K 4 Fe(CN) 6 ·3H 2 O was dissolved in 50ml deionized water, stirred and mixed by a magnetic stirrer to obtain solution B.

[0056] Preparation of KPB nanoparticles: Add solution B to solution A dropwise, stirring continuously during the dropping process, after stirring for a tot...

Embodiment 2-4

[0086] The preparation method of Examples 2-4 is the same as that of Example 1, the difference lies in the flow rates of hydrogen and methane when VG is grown on the flexible carbon cloth substrate. The specific flow rate regulation in the preparation method of Examples 2-4 is shown in Table 1. The N,P-VG@CC nanomaterial prepared in Example 2-4 was used to assemble and prepare a fully flexible potassium ion battery, and the energy storage of the fully flexible potassium ion battery was studied by referring to the same constant current charge and discharge test method as in Example 2 above. performance. The fully flexible potassium ion battery prepared in embodiment 1 is at 50mAg -1 The corresponding specific capacity is 116.25mA h g -1 , the fully flexible potassium-ion battery prepared in test example 2-4 was tested at 50mA g -1 When the corresponding specific capacity.

[0087] Table 1 Flow rate regulation of hydrogen and methane

[0088]

Embodiment 5-7

[0090] The preparation method of Examples 5-7 is the same as that of Example 1, except that the temperature and time of doping heating are different when VG is grown on the flexible carbon cloth substrate. The specific heating time and heating temperature of doping heating in the preparation method of Examples 5-7 are shown in Table 2. Using the N,P-VG@CC nanomaterials prepared in Examples 5-7 to assemble and prepare a fully flexible potassium ion battery, refer to the same constant current charge and discharge test method as in Example 2 above to study the energy storage of the fully flexible potassium ion battery performance. The fully flexible potassium ion battery prepared in Example 1 still had a capacity retention rate of 86.9% after 150 continuous charge and discharge times, and the capacity retention rate of the fully flexible potassium ion battery prepared in Examples 5-7 was tested after 150 continuous charge and discharge times.

[0091] Table 2 Heating time and he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com