A kind of cross-linking degree test curve fitting formula method and cross-linking degree detection method

A technology of cross-linking degree and detection value, which is applied in the direction of transmittance measurement, geometric CAD, CAD numerical modeling, etc., can solve the problems of on-site production impact, use risk and cost, and long cycle, so as to achieve zero operation risk and improve The effect of detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

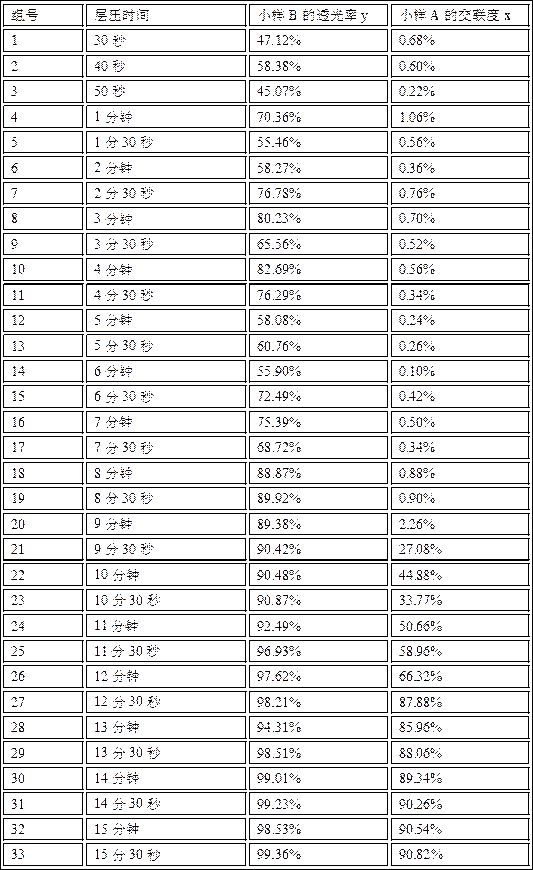

[0023] At the same room temperature, take small experimental samples A and B of the same specification, and laminate them at the same position of the same laminator, send the laminated small sample A to the routine experiment of benzene extraction, and obtain the detection value x of the cross-linking degree, after lamination The light transmittance test of the small sample B is carried out to obtain the light transmittance value y, the detection value x of the benzene extraction crosslinking degree and the light transmittance value y form a data set, adjust the lamination time, and the lamination time starts from 30 seconds. A total of 33 data sets were obtained:

[0024]

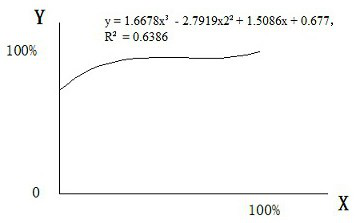

[0025] The above-mentioned appropriate 33 data groups are used to establish the curve diagrams of small sample A and small sample B, see attached figure 1 As shown, the relationship between the cross-linking detection value x and the light transmittance value y obtained by fitting the graph is: y = 1.66...

Embodiment 2

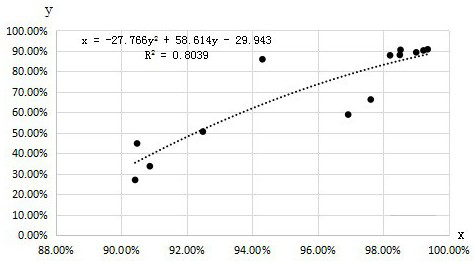

[0027] In Example 1, the cross-linking degree detection value x only selects the range of 20%-100% and arranges them in order from low to high, that is, the data group whose group number is 21-33, and establishes the data sets of small sample A and small sample B. The graph, specifically attached figure 2 As shown in the graph, the relationship between the crosslinking degree detection value x and the light transmittance value y obtained by fitting the graph is: y = -0.0754x² + 0.2289x +0.8396, R² = 0.8038.

[0028] The formula for calculating the degree of cross-linking is deduced from this formula: x=-27.766y² + 58.614y - 29.943, R² =0.8039.

[0029] According to the calculation formula x=-27.766y² + 58.614y - 29.943, the method for detecting the degree of cross-linking set by R² = 0.8039 includes the following steps:

[0030] s1: Use a laminator to make a cross-linked EVA sample;

[0031] s2: the light transmittance value y of the small sample in the test step s1;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com