Fuel filter core with safety valve

A technology of fuel filter element and safety valve, applied in the field of fuel filter element, can solve problems such as engine damage, and achieve the effect of avoiding air resistance and damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

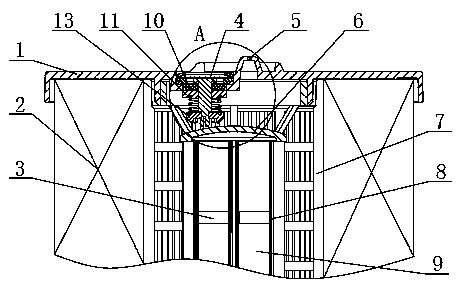

[0038] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

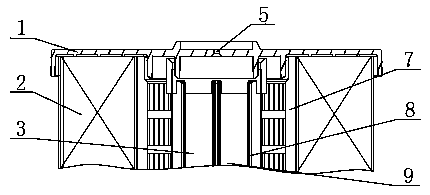

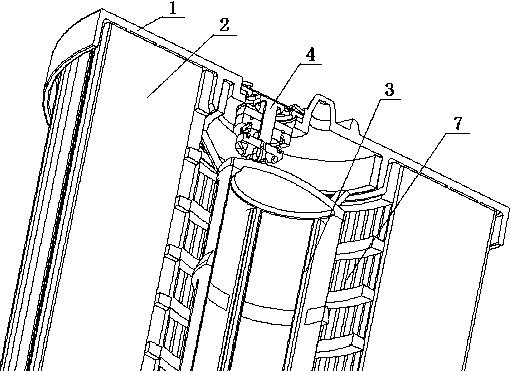

[0039] Such as figure 2 , image 3 As shown, the present invention is vertically and concentrically arranged with a filter layer 2 and a hydrophobic pipe assembly 3 between the circular upper end cap 1 and the lower end cap (not shown in the figure), and the filter layer 2 divides the filter element into an inner and an outer; the hydrophobic The tube assembly 3 is a cylindrical structure and is located in the center of the filter element. The outer periphery of the drain pipe assembly 3 is provided with a filter screen 8 through the support ribs, the drain cavity 7 is formed between the outside of the filter screen 8 and the filter layer 2 , and the flow channel 9 is inside. The top of the drain pipe assembly 3 is provided with a diversion surface 6, the diversion surface 6 is a closed arc-shaped spherical surface protruding toward the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com