An Efficient Coupling Method of Anodic Oxidation to Produce Hypochlorite and Cathodic Reduction of Carbon Dioxide

A technology of carbon dioxide and hypochlorite, which is applied in the field of catalysis, can solve the problems of catalyst deactivation, and achieve the effect of less metal loading, no danger, and easy synthesis conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

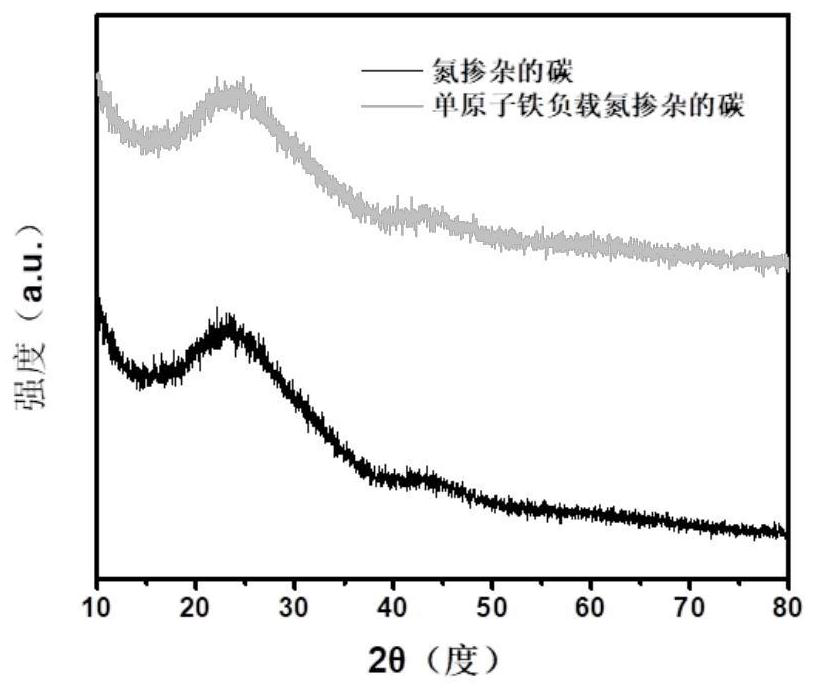

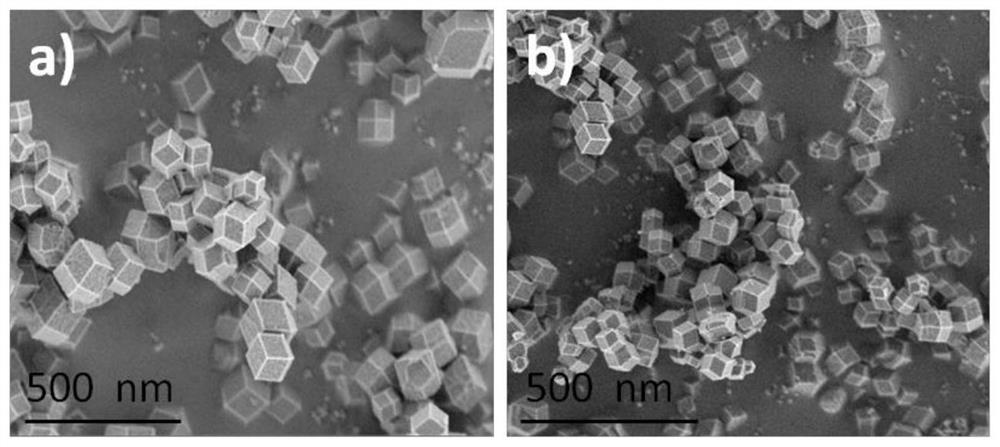

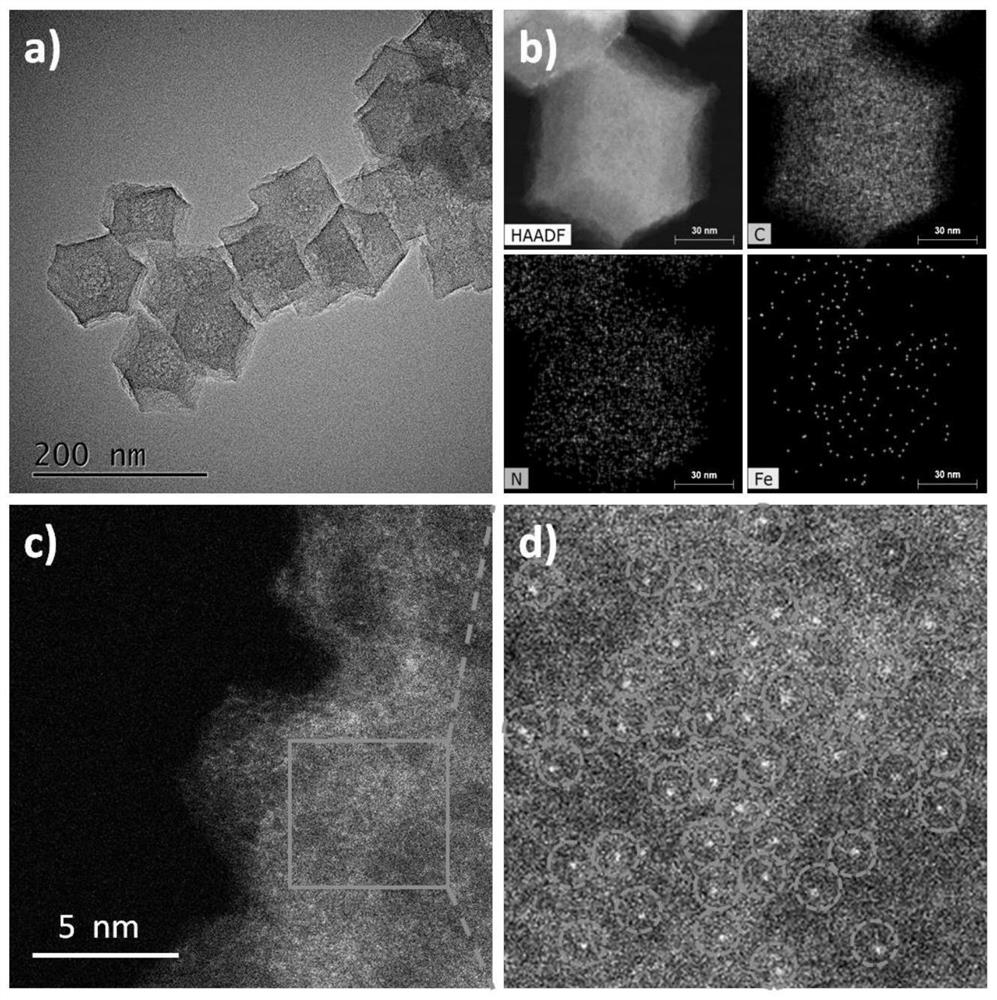

[0039] Preparation of monoatomic iron-supported nitrogen-doped carbon materials:

[0040] Dissolve 0.5g of zinc nitrate hexahydrate in 10mL of methanol to obtain liquid A, and dissolve 0.55g of dimethylimidazole in 10mL of methanol to obtain liquid B. Add liquid A to liquid B, ultrasonicate, and react at 30°C for 10 hours. The solid product after the reaction was collected by centrifugation, washed three times with DMF and methanol respectively, and the washed solid product was collected by centrifugation, and dried in a vacuum oven at 80°C to obtain ZIF-8; take 0.1g of the above ZIF-8 powder and add 10ml 0.01 % iron acetylacetonate in tetrahydrofuran solution, sonicate for 1h to make it fully and evenly mixed; vacuum for 1h to obtain a solid powder; calcinate the above powder at 950°C for 2h in an Ar atmosphere, and after naturally cooling to room temperature, collect the reaction product to obtain Nitrogen-doped carbon supported on monoatomic iron. Tested by IPC-OES, the ir...

Embodiment 2

[0050] Construction of the electrolysis system:

[0051] Weigh 10 mg of monoatomic iron-supported nitrogen-doped carbon as a precursor, ultrasonically disperse it into a mixture of 1 mL of Nafion (2 wt%) and isopropanol, and then add 150 μL of monoatomic iron-supported nitrogen-doped carbon suspension to 1cm on the surface 2 The surface of the glassy carbon electrode was dried under an infrared lamp to prepare a nitrogen-doped carbon / glassy carbon electrode supported by single-atom iron. The catalyst loading in the electrode was 1.5mg / cm 2 .

[0052] In an electrolytic cell separated by a proton exchange membrane into an anode tank and a cathode tank, the nitrogen-doped carbon catalyst electrode supported by monoatomic iron is used as the working electrode (cathode), the ruthenium titanium is the auxiliary electrode (anode), and the anode and catholyte solutions are 0.1M sodium chloride solution, carbon dioxide is passed into the cathode tank to saturation, and then electric...

Embodiment 3

[0058] Realization of electrocatalytic cathode reduction of CO2 and anode production of hypochlorite:

[0059] When carbon dioxide is reduced at a cell pressure of 1.0V, the current efficiency of carbon monoxide is 33.99%, and the current efficiency of hypochlorite produced by the anode is 23.75%. The current efficiency of chlorate is 51.47%; the current efficiency of reducing carbon dioxide and carbon monoxide is 81.22% under the cell pressure of 2.0V, and the current efficiency of hypochlorite produced by the anode is 78.195%; reducing carbon dioxide and carbon monoxide under the cell pressure of 2.5V The current efficiency is 99.63%, the current efficiency of hypochlorite produced by the anode is 99.47%, the carbon monoxide is reduced at a cell voltage of 3.0V, the current efficiency of carbon monoxide is 99.21%, and the current efficiency of hypochlorite produced by the anode is 99.08%. Experimental results such as Figure 8 Shown: When the tank voltage is 2.5V, its Farad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com