Preparation method of high-dispersion plant fiber absorption material

A technology of plant fibers and absorbent materials, which is applied in the field of preparation of highly dispersed plant fiber absorbent materials, can solve problems affecting the performance of hygienic absorbent materials, disordered and random stacking of fibers, and fiber dough effect, etc., to improve surface structure performance and improve Dispersion performance, long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

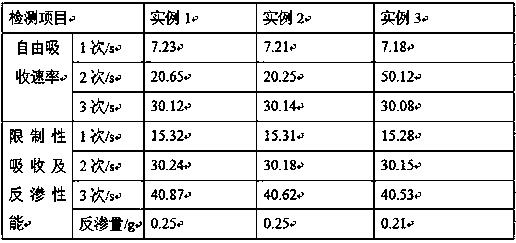

example 1

[0031] Take fresh camphor leaves, wash and dry them, crush them with airflow and use liquid nitrogen to quick-freeze them, collect the freeze-dried particles and place them in a tissue grinder to grind through a 200-mesh sieve. After thawing for 2 hours, the extracted particles are obtained; then the mass ratio is 1 : 25. Add the extracted particles to the 15% ethanol solution, stir and mix and soak for 10 hours, then centrifuge at 4500r / min for 15min, take the supernatant and place it at 40℃ to rotate and evaporate to the volume of the supernatant 1 / 5, get the rotary steaming liquid, and then prepare the camphor leaf essential oil; in parts by weight, respectively weigh 45 parts of camphor leaf essential oil, 10 parts of 85% ethanol solution and 25 parts of 30% by weight. The sulfuric acid solution was placed in a beaker, stirred and mixed, and kept at 45°C for 6 hours. After cooling to room temperature, the reaction solution was obtained and placed in a separatory funnel. Afte...

example 2

[0033] Take fresh camphor leaves, wash and dry them, pulverize with airflow and quickly freeze them with liquid nitrogen, collect the freeze-dried particles and place them in a tissue grinder to grind through a 200-mesh sieve. After thawing for 3 hours, the extracted particles are obtained; then the mass ratio is 1 : 25. Add the extracted particles to a 15% ethanol solution, stir and mix and soak for 11 hours, then centrifuge at 4750r / min for 17 minutes, take the supernatant and place it at 42°C by rotary evaporation to the volume of the supernatant 1 / 5, the rotary steaming liquid is obtained, and the described camphor leaf essential oil can be prepared; in parts by weight, respectively weigh 47 parts of camphor leaf essential oil, 12 parts of 85% ethanol solution and 27 parts of 30% by weight. The sulfuric acid solution was placed in a beaker, stirred and mixed, and kept at 47°C for 7h to react with heat. After standing and cooling to room temperature, the reaction solution was...

example 3

[0035] Take fresh camphor leaves, wash and dry them, pulverize with airflow and quickly freeze them with liquid nitrogen, collect the freeze-dried particles and place them in a tissue grinder to grind through a 200-mesh sieve. After thawing for 3 hours, the extracted particles are obtained; then the mass ratio is 1 : 25. Add the extracted particles to the 15% ethanol solution, stir and mix and soak for 12 hours, then centrifuge at 5000r / min for 20min, take the supernatant and place it at 45℃ to rotate and evaporate to the volume of the supernatant 1 / 5, to obtain the rotary steaming liquid, the said camphor leaf essential oil can be prepared; in parts by weight, respectively weigh 50 parts of camphor leaf essential oil, 15 parts of 85% ethanol solution and 30 parts of 30% by weight. The sulfuric acid solution was placed in a beaker, stirred and mixed and placed at 50°C for 8 hours to keep warm, and allowed to stand to cool to room temperature. The reaction solution was obtained a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com