Automotive painting electrophoresis waste water preprocessing system and method

A coating electrophoresis and pretreatment technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of difficult to meet discharge standards, unstable effluent quality, and poor treatment effect Ideal and other issues, to achieve the effect of small footprint, easy sludge discharge, and short settling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

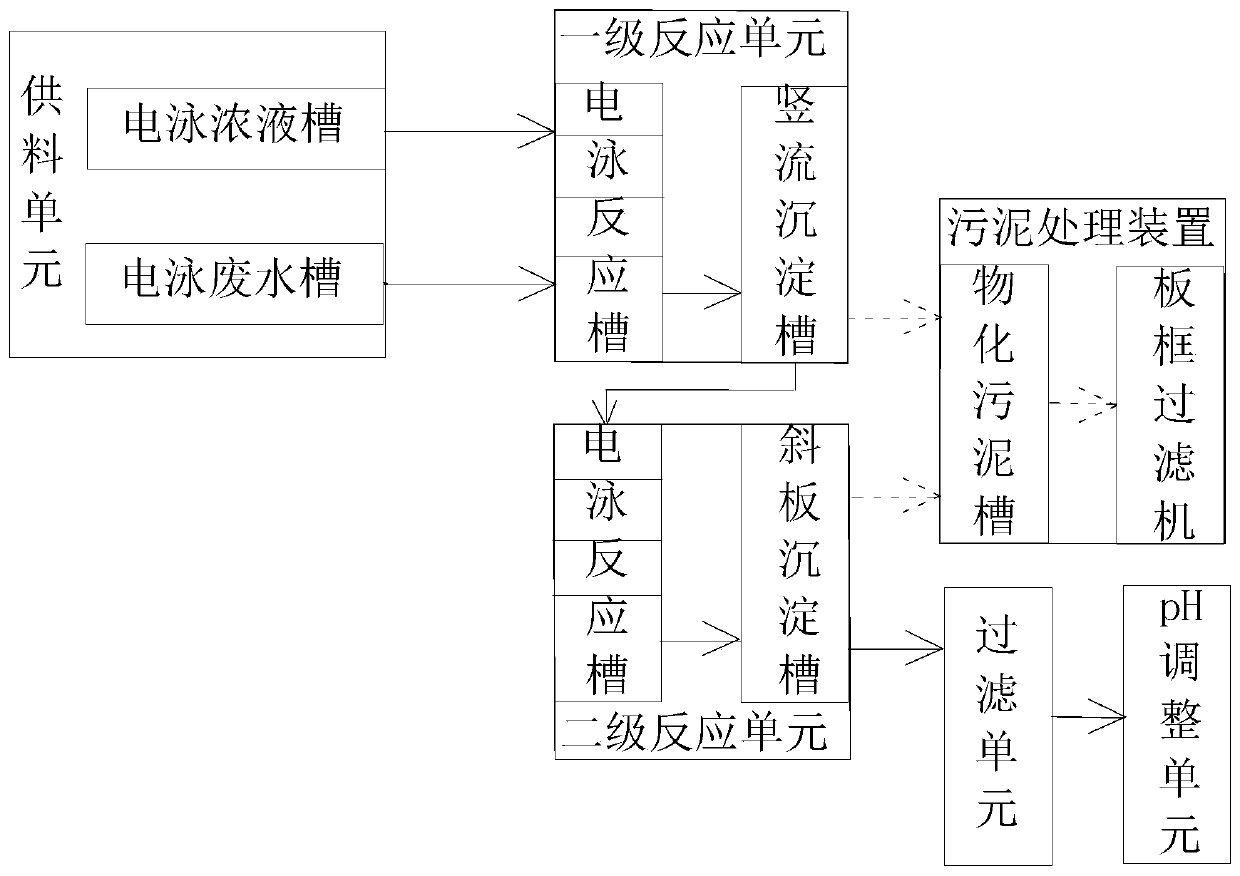

[0037] Such as figure 1 As shown, the present invention provides a kind of electrophoretic wastewater pretreatment system for automobile coating, comprising a feeding unit, a reaction unit, a filtering unit and a pH adjustment unit connected in sequence; the feeding unit is used to receive and accommodate wastewater containing electrophoretic liquid; The reaction unit includes an electrophoresis reaction tank and a sedimentation tank connected in sequence. The sedimentation tank includes a liquid discharge port and a sludge discharge port (not marked in the figure, the dotted line in the figure is the sludge flow direction, and the solid line is the filtrate flow direction), the liquid discharge port and the sludge discharge port The filter units are connected, and a sludge treatment device is installed at the sludge discharge port; among them, there are two reaction units, which are the primary reaction unit and the secondary reaction unit connected in series, and the sediment...

Embodiment 2

[0043] The present invention provides a method for pretreatment of electrophoresis wastewater from automobile coating, which is based on the above system and includes the following steps:

[0044] (1) Primary coagulation reaction

[0045] Add NaOH to the phosphating wastewater produced by the second-phase coating wastewater station of the FAW-Volkswagen Foshan plant (the average COD of the electrophoresis influent is 3300mg / L) until the pH value reaches 9.9, and react for 10 minutes; then add lime milk to adjust the pH value 10, and stir for 10 minutes; then add polyaluminum chloride and stir for 15 minutes; finally add anionic polyacrylamide and stir for 15 minutes to obtain a primary treatment solution;

[0046] (2) Primary precipitation separation

[0047] The primary treatment liquid is injected into the vertical flow sedimentation tank for primary sedimentation and separation to obtain the primary filtrate and primary mud, and the primary mud is concentrated and then dew...

Embodiment 3

[0055] The present invention provides a method for pretreatment of electrophoresis wastewater from automobile coating, which is based on the above system and includes the following steps:

[0056] (1) Primary coagulation reaction

[0057] Add NaOH to the rinse solution produced in the electrophoresis area of the waste water station of the Tianjin factory (the average water inflow of the electrophoresis line is 1800mg / L) to a pH value of 10.5, and react for 15 minutes; then add milk of lime, adjust the pH value to 10.5, and stir for 15 minutes ; Then add polyaluminum chloride and stir for 15 minutes; finally add anionic polyacrylamide and stir for 15 minutes to obtain a primary treatment solution;

[0058] (2) Primary precipitation separation

[0059] The primary treatment liquid is injected into the vertical flow sedimentation tank for primary sedimentation and separation to obtain the primary filtrate and primary mud, and the primary mud is concentrated and then dewatered ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com