Method for preparing metal oxide nanosheet with quantum size by taking biomass as template

A biomass and oxide technology, applied in the field of materials, can solve the problems of difficult separation, increased use cost, low catalyst utilization efficiency, etc., and achieves the effect of simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Grind the carbonized biomass template (50mg) with a hierarchical structure evenly, immerse it in 5ml titanyl sulfate solution (1M), soak for 7h, then suction filter and fully wash away the free titanyl sulfate, and freeze-dry the product ;

[0023] (2) The biomass material after step (1) was freeze-dried in N 2 Annealing at 650°C for 3 hours under atmosphere to prepare biomass-metal oxide composites;

[0024] (3) Annealing the composite material obtained in step (2) at 450° C. in an air atmosphere to remove the carbon layer to obtain a sheet structure composed of titanium dioxide nanoparticles.

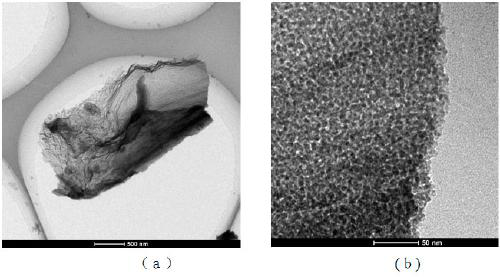

[0025] The X-ray diffraction spectrogram confirms that the preparation method has successfully synthesized titanium dioxide (refer to attached figure 1 ). Transmission electron microscope photos show that this method successfully obtains a two-dimensional sheet structure composed of nanoparticles, and the particle size of the nanoparticles is 3-5 nanometers (see figure...

Embodiment 2

[0027] (1) Grind the carbonized biomass template (50 mg) with a hierarchical structure evenly, immerse it in 5 ml of nickel acetate (0.2 M), soak for 7 hours, then suction filter and fully wash away the free nickel acetate, and freeze-dry the product;

[0028] (2) The biomass material after step (1) was freeze-dried in N 2 Annealing at 650°C for 3 hours under atmosphere to prepare biomass-metal oxide composites;

[0029] (3) Anneal the composite material obtained in step (2) at 500° C. for 1 h in an air atmosphere, remove the carbon layer, and obtain a sheet structure composed of nickel oxide nanoparticles.

Embodiment 3

[0031] (1) Grind the carbonized biomass template (50 mg) with a hierarchical structure evenly, immerse it in 5 ml of cobalt acetate (0.2 M), soak for 7 hours, then suction filter and fully wash away the free cobalt acetate, and freeze-dry the product;

[0032] (2) The biomass material after step (1) was freeze-dried in N 2 Annealing at 500°C for 3 hours under atmosphere to prepare biomass-metal oxide composites;

[0033] (3) Anneal the composite material obtained in step (2) at 500° C. for 1 h in an air atmosphere, remove the carbon layer, and obtain a sheet structure composed of cobalt trioxide nanoparticles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com