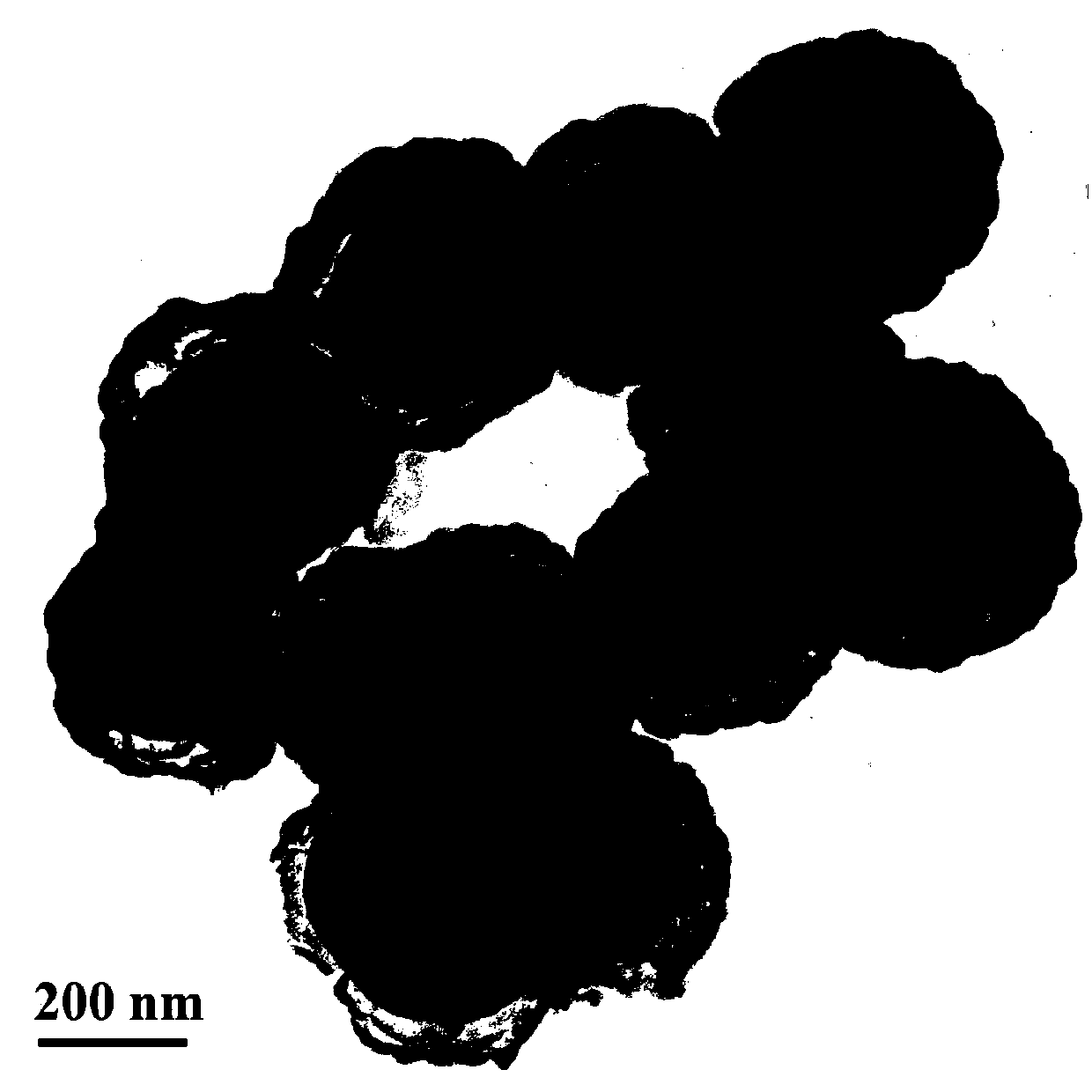

Mesoporous silicon dioxide material with eggshell-yolk structure and preparation method of mesoporous silicon dioxide material

A technology of mesoporous silica and egg yolk structure, applied in the direction of silica, silicon oxide, nanotechnology, etc., can solve the problems of high price, low porosity, cumbersome steps, etc., and achieve simple and easy preparation process, good shape Regular and adjustable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Get 2g of cetyltrimethylammonium bromide and dissolve it in 60ml of absolute ethanol and 100ml of deionized water, add 3ml of ammonia water with a mass concentration of 28%, 0.5ml of ethyl orthosilicate, 0.2g of resorcinol, 0.3 ml formaldehyde solution, stirred at 40°C for 6h, then added 0.3ml tetraethyl orthosilicate, continued to stir for 6h, filtered out the solid product, dried and roasted at 550°C for 4h to obtain eggshell-yolk structured mesoporous silica.

Embodiment 2

[0016] Take 2g of cetyltrimethylammonium bromide and dissolve it in 60ml of absolute ethanol and 100ml of deionized water, add 3ml of ammonia water with a mass concentration of 25%, 4ml of ethyl orthosilicate, 0.2g of resorcinol, and 0.3ml of Stir the formaldehyde solution at 40°C for 6h, then add 0.5ml tetraethyl orthosilicate, continue to stir for 6h, filter out the solid product, dry it and bake it at 550°C for 4h to obtain mesoporous silica with eggshell-yolk structure.

Embodiment 3

[0018] Get 3g cetyltrimethylammonium bromide and dissolve in 60ml absolute ethanol and 100ml deionized water, add 3ml mass concentration 28% ammonia water, 0.5ml tetraethyl orthosilicate, 0.6g resorcinol, 0.9 ml formaldehyde solution, stirred at 40°C for 6h, then added 0.5ml tetraethyl orthosilicate, continued to stir for 6h, filtered out the solid product, dried and roasted at 550°C for 4h to obtain eggshell-yolk structured mesoporous silica.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com