Metal and asphalt composite tile for special-shaped roof and preparation method thereof

A kind of asphalt and metal technology, applied in the field of metal and asphalt composite tiles and its preparation, can solve the problems of lack of thick coating, high cost, long construction period, etc., and achieve the solution of low safety, long service life and rich colors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the embodiments. It should be noted that the described embodiments are only intended to facilitate the understanding of the present invention, and have no limiting effect on it.

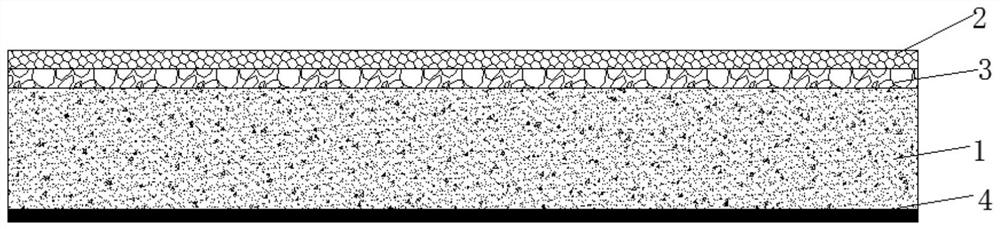

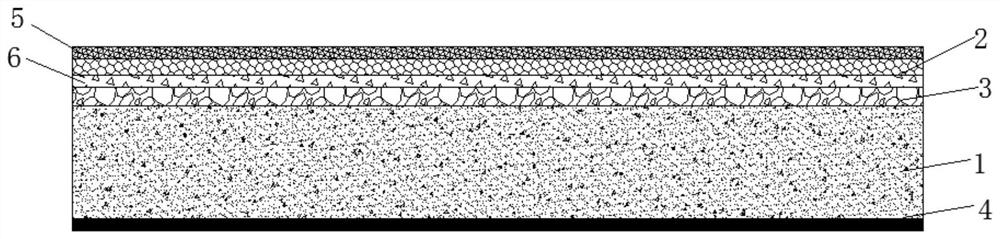

[0037] Such as figure 1 As shown, a metal and asphalt composite tile for special-shaped roofs provided by the present invention includes an asphalt base 1 and a metal layer 2 provided with a surface coating, and the asphalt base 1 and the metal layer 2 provided with a surface coating There is an adhesive layer 3 for bonding the metal layer 2 provided with the surface coating and the asphalt base 1, the lower part of the asphalt base 1 is provided with a protective film 4, and the metal layer 2 provided with the surface coating A surface coating 5 is provided on the upper part; the asphalt base 1 is made of flexible materials. The metal and asphalt composite tile used for special-shaped roofs provided by the present in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| brittleness temperature | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com