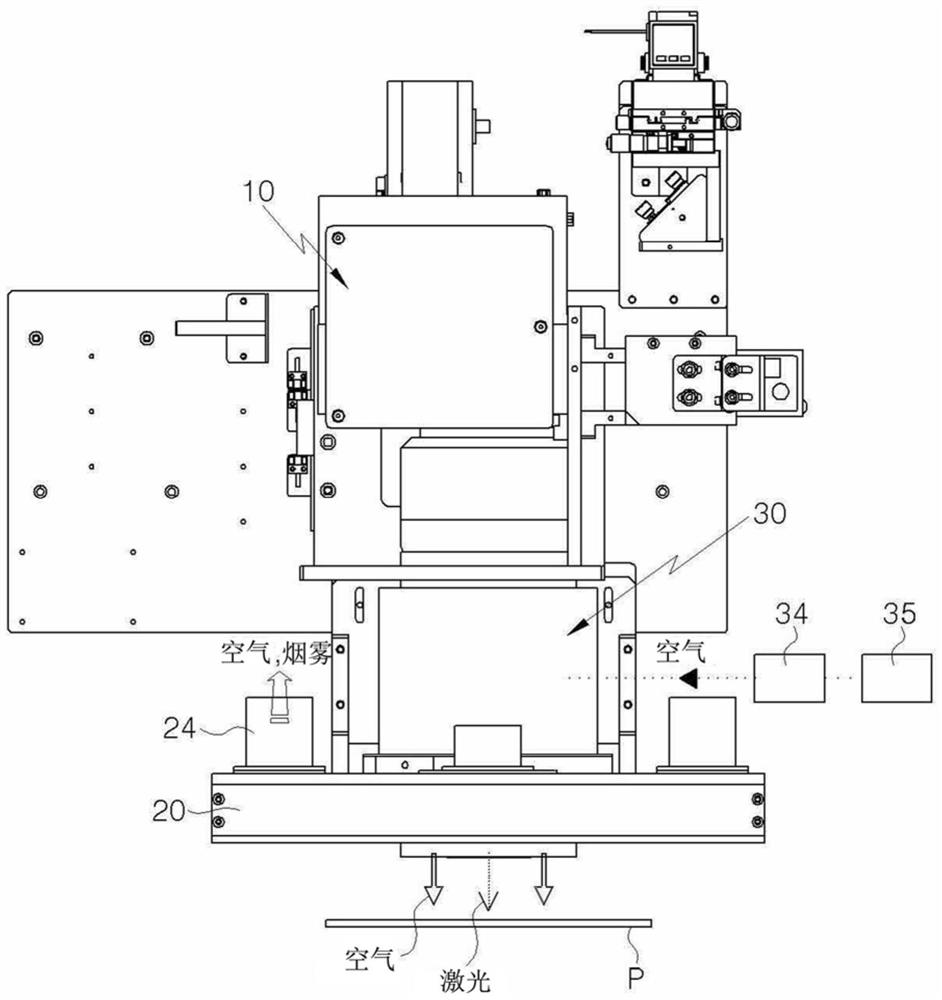

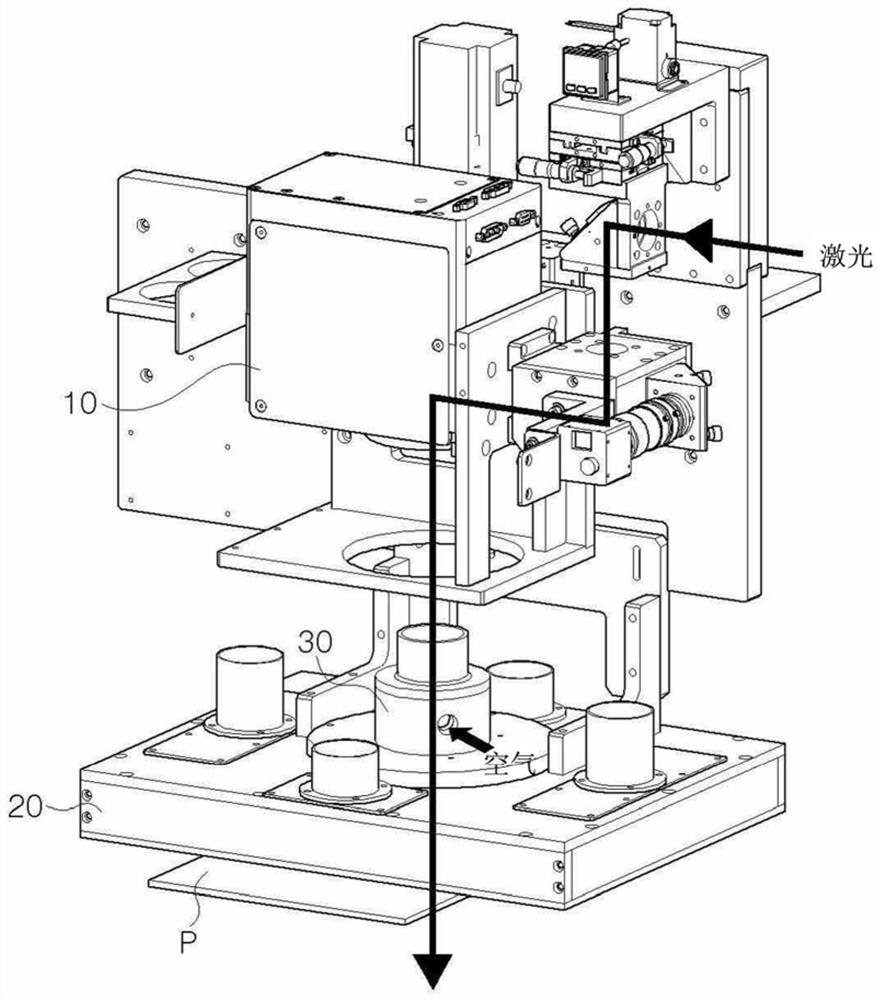

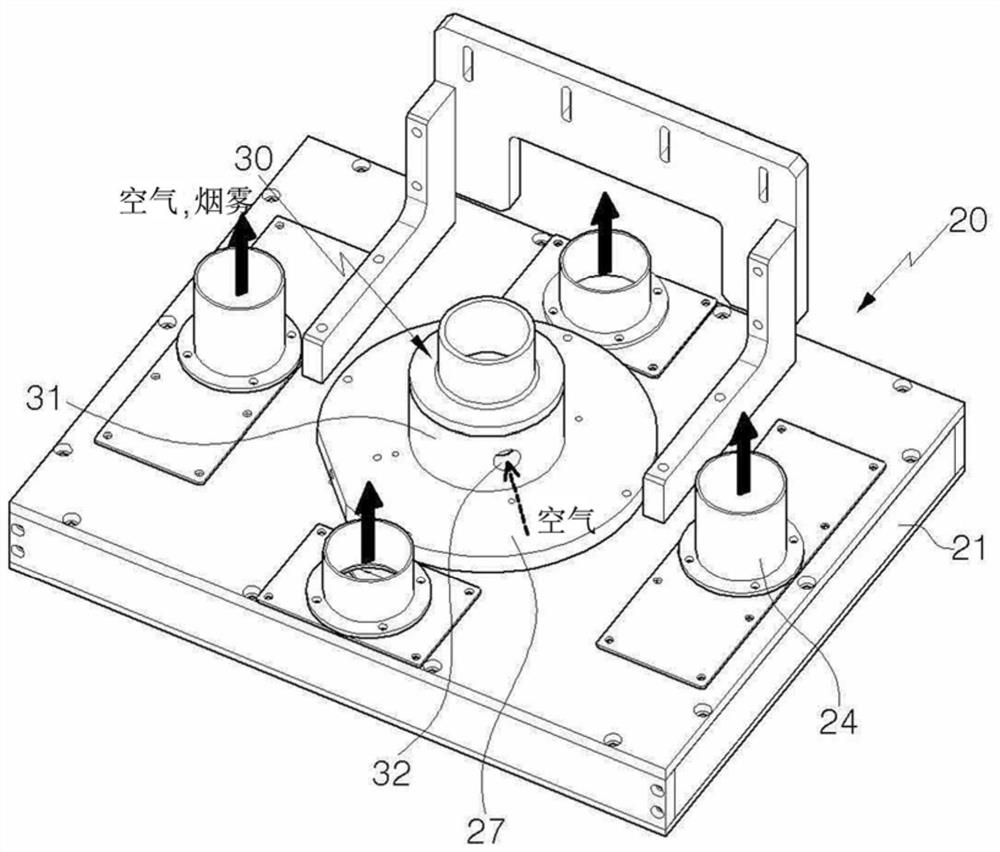

Laser and air suction hole dual-purpose laser processing scanning head

A technology of laser processing and air inhalation, which is applied in laser welding equipment, metal processing equipment, manufacturing tools, etc. It can solve the problems of quality degradation and pollution of the processing object, and achieve the effect of increasing the speed and preventing the effect of laser scattering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Before describing multiple embodiments of the present invention in detail, it should be understood that its application is not limited to the details of the structure and arrangement of the structural elements described in the following detailed description or shown in the accompanying drawings. The invention can be embodied and practiced in other embodiments and in various ways of being carried out. And, in the direction of the device or element (for example, "front (front)", "back (back)", "up (up)", "down (down)", "top (top)", "lower (bottom), "left", "right", "lateral"), it should be understood that the expressions and terms used in this application are for simplification only The description of the present invention does not represent or imply that the relevant devices or elements simply have a specific direction. Moreover, in the process of description, terms such as "first" and "second" are used in this application and the protection scope of the invention, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com