Carbon nitride photocatalytic material with high visible light absorption and its preparation method and application

A carbon nitride and dosage ratio technology, applied in the field of materials, can solve the problems of low photogenerated electron hole separation efficiency, small specific surface area of carbon nitride, low photocatalytic activity, etc., and achieve excellent photocatalytic degradation activity and mild reaction conditions. , The effect of rich and clean raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

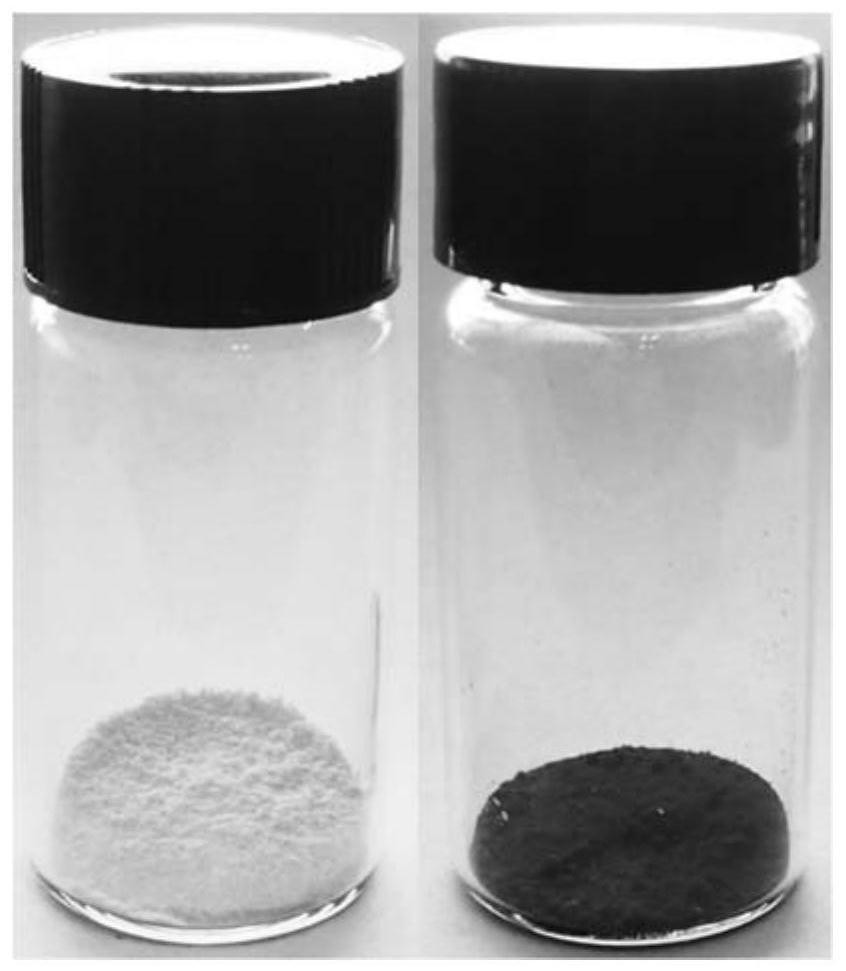

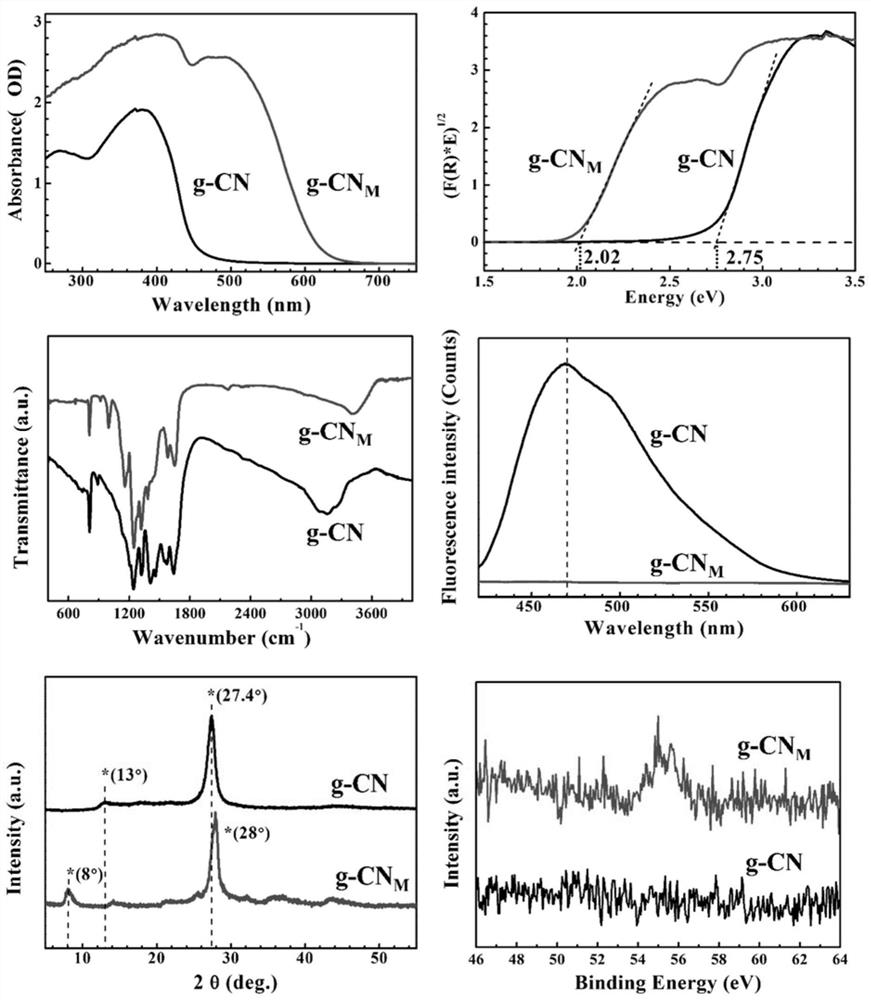

[0039] Example 1, g-CN M preparation of

[0040] 1) Take 10g of melamine for thermal polymerization in a muffle furnace. The specific conditions are to heat up to 500°C at 10°C / min, keep it for 4h, and cool down naturally to obtain the precursor g-CN, which is ground evenly for later use (the yield is about 50%) .

[0041] 2) Weigh 600 mg of the above sample, grind it with KCl (3.3 g) and LiCl (2.7 g) in a nitrogen atmosphere in a glove box to obtain 6.6 g of a mixed powder sample, and place the mixed powder sample in a tube furnace under a nitrogen atmosphere Raise the temperature to 550°C at a rate of 10°C / min (nitrogen flow rate 2L / min), keep it for 4h, cool down naturally, grind evenly, wash with deionized water several times, and vacuum dry at 60°C under 0.1MPa for 12h to obtain 595mg of intermediate samples, namely salt Melted g-CN.

[0042] 3) Weigh 50 mg of the salt-melted g-CN of the above intermediate sample and add it to 50 mL of isopropanol, drop 4 drops (about ...

Embodiment 2

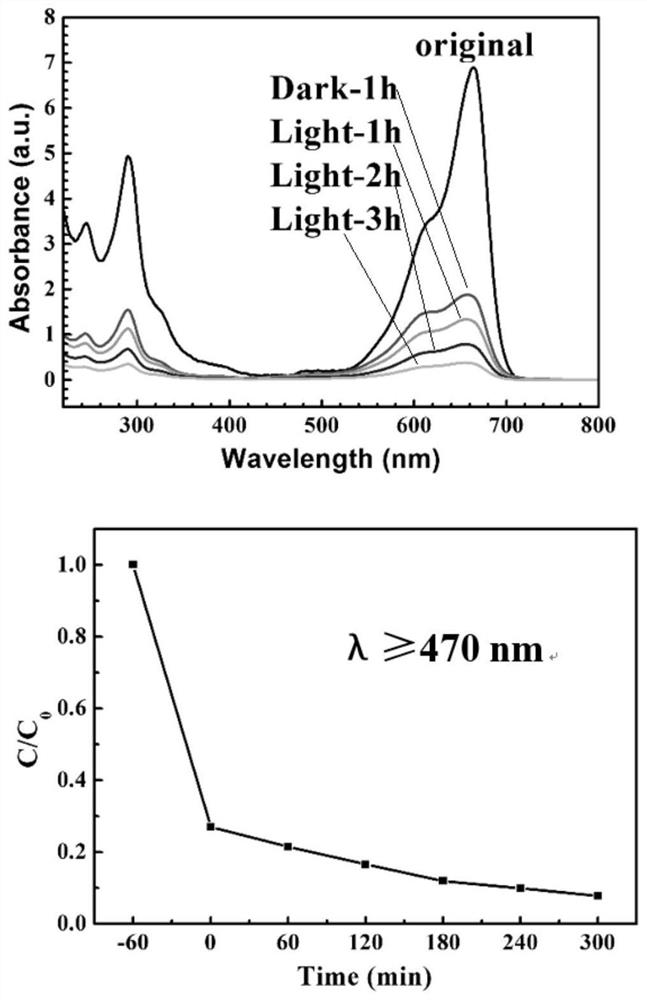

[0048] Able to achieve efficient photocatalytic degradation of water pollutant methylene blue: 20mg catalyst g-CN M Added to 100mL of methylene blue (Methylene Blue, MB) solution with a concentration of 30mg / L, fully stirred for 60min in a dark environment to achieve the adsorption and desorption equilibrium of the catalyst to the target degradation product solution, and the adsorption capacity of the sample to the dye was also very prominent. After equilibrium About 80% of the dye was adsorbed, and then the solution was placed under a 300W xenon lamp light source and a filter of λ≥470nm was irradiated. Samples were taken every 1h, and the degradation was complete after 3h, showing excellent degradation efficiency, such as figure 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com