Electronic cigarette atomizer, electronic cigarette, atomizing assembly and preparation method of atomizing assembly

A technology for electronic cigarette atomizers and atomization components, which is applied in the field of electronic cigarette atomizers, atomization components and their preparation, and electronic cigarettes. Guarantee the effect of consistency and tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

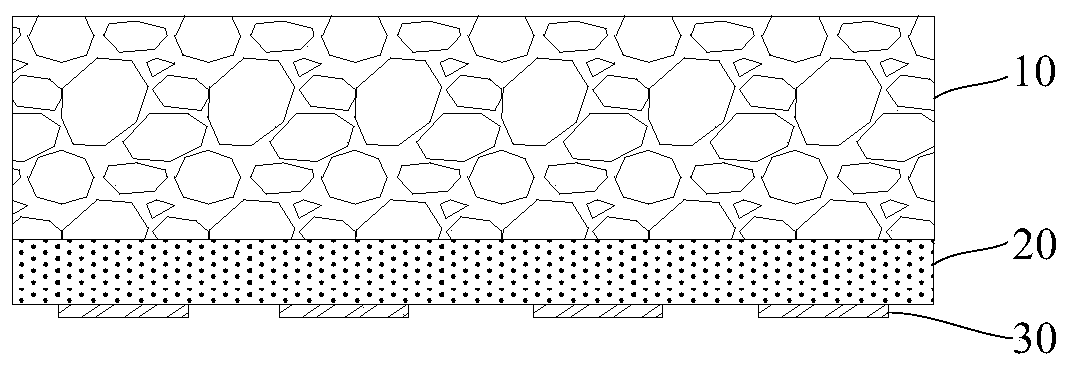

[0043] Based on the above description of the structure and material of the atomization component, the present invention further proposes a preparation method of the above atomization component, which is carried out by tape casting as a whole. In one embodiment, the preparation process includes the following steps:

[0044] S10, mixing the ceramic material powder for forming the porous body 10, the pore-forming agent and the casting aid to make a first casting slurry, and making a plurality of first casting films through a casting process;

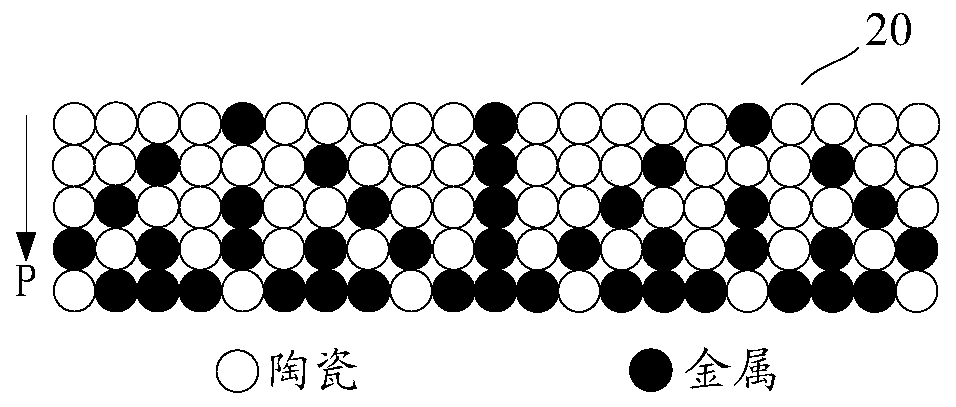

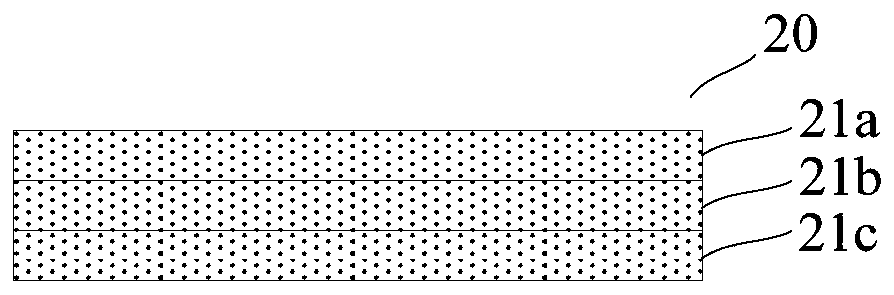

[0045] S20, mixing the ceramic and metal mixed material powder, pore forming agent and casting aid used to form the porous transition layer 20 to make a second casting slurry, and making a number of second casting membranes through a casting process ;

[0046] S30, mixing the metal material powder for forming the heating element 30 and the casting aid to make a third casting slurry, and making a plurality of third casting films through a ca...

Embodiment 1

[0058] S10, the alumina powder with an average particle size of 60 μm obtained by ball milling and the PMMA microsphere pore-forming agent with an average particle size of 50 μm are mixed according to a weight ratio of 60:20, and then 1.2 times the weight of composite auxiliary agent for casting and film formation is added. Prepare the first casting slurry with a thick film casting machine to form a number of first casting films with a thickness of 100 μm and a size of 6 to 10 inches;

[0059] S21, the alumina powder obtained by ball milling with an average particle size of 60 μm is mixed with nickel-chromium alloy powder at a weight ratio of 4:1, and then added with an average particle size of 50 μm at a weight ratio of 60:20 between the mixed powder and the pore-forming agent. After the PMMA microsphere pore-forming agent mixes, then add 1.2 times of weight casting film-forming composite auxiliary agent (commercially available) to be prepared into some second cast slurry; Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com