Preparation method of flavored nutritious crisp apple chips

A technology of apple slices and apples, which is applied in the field of food processing, can solve the problems that patents of fruit and vegetable products are rarely seen in relevant reports, etc., and achieve the effect of improving nutritional value and eating population, expanding eating population, and improving nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A preparation method for flavor apple nutritious chips, comprising the following steps:

[0033] (1) Pretreatment: select crisp apples with a maturity of 80%, no damage, no pests and diseases, remove the stem, peel and core, and slice to obtain apple slices with a thickness of 4-5mm.

[0034] (2) Blanching: put the apple slices in boiling water for 120 seconds, and then quickly place them in water at a temperature of 20° C. for 60 seconds.

[0035] (3) Dipping; the blanched apple slices are placed in a dipping solution at a temperature of 55°C; the mass ratio of the apple slices to the dipping solution is 1:10; the dipping is placed under vacuum for 15 minutes , and then placed under normal atmospheric pressure for 16 minutes.

[0036] The dipping solution is made by mixing rose extract and ferric pyrophosphate solution; the mass ratio of rose extract and ferric pyrophosphate solution is 1:8;

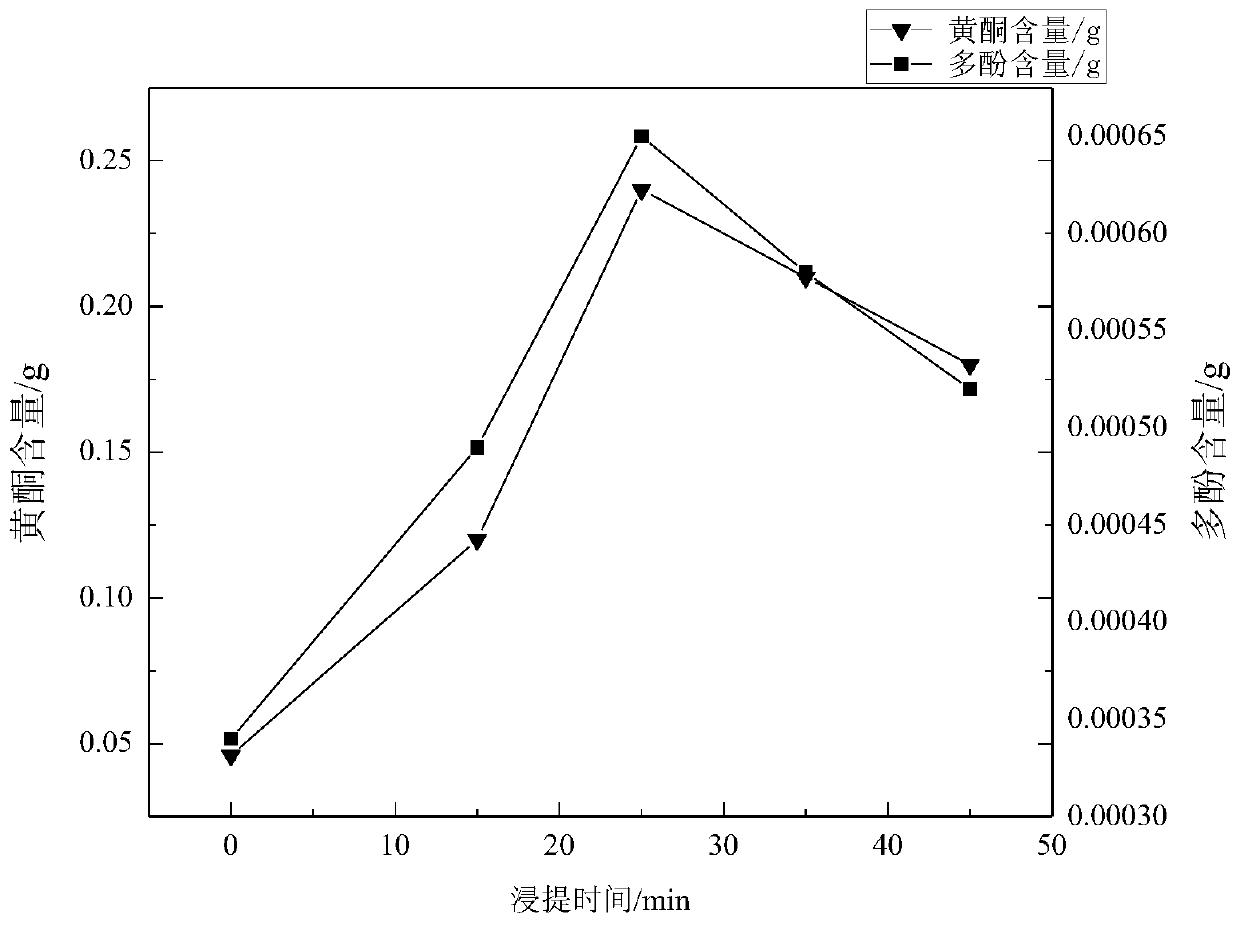

[0037] The preparation method of the rose extract comprises the following ...

Embodiment 2

[0042] A preparation method for flavor apple nutritious chips, comprising the following steps:

[0043] (1) Pretreatment: select crisp apples with a maturity of 70%, no damage, no pests and diseases, remove the stem, peel and core, and slice to obtain apple slices with a thickness of 4-5 mm.

[0044](2) Blanching; place the apple slices in boiling water for 150 seconds, then quickly place them in water at a temperature of 25° C. for 90 seconds.

[0045] (3) Dipping; the blanched apple slices are placed in a dipping solution at a temperature of 70°C; the mass ratio of the apple slices to the dipping solution is 1:12; the dipping is placed under vacuum for 20 minutes , and then placed under normal atmospheric pressure for 20 minutes.

[0046] The dipping solution is made by mixing rose extract and ferric pyrophosphate solution; the mass ratio of rose extract and ferric pyrophosphate solution is 1:10;

[0047] The preparation method of the rose extract comprises the following s...

Embodiment 3

[0052] A preparation method for flavor apple nutritious chips, comprising the following steps:

[0053] (1) Pretreatment: select crisp apples with a maturity of 70%, no damage, no pests and diseases, remove the stem, peel and core, and slice to obtain apple slices with a thickness of 4-5 mm.

[0054] (2) Blanching; place the apple slices in boiling water for 100 seconds, then quickly place them in water at a temperature of 15° C. for 30 seconds.

[0055] (3) Dipping; the blanched apple slices are placed in a dipping solution at a temperature of 40°C; the mass ratio of the apple slices to the dipping solution is 1:8; the dipping is placed under vacuum for 10 minutes , and then placed under normal atmospheric pressure for 10 minutes.

[0056] The dipping solution is made by mixing rose extract and ferric pyrophosphate solution; the mass ratio of rose extract and ferric pyrophosphate solution is 1:6;

[0057] The preparation method of the rose extract comprises the following st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com