Super-power five-cylinder plunger pump

A super-high-power, cylinder-column technology, applied to multi-cylinder pumps, piston pumps, pumps, etc., can solve the problems of multiple fracturing equipment matching, high-power motors that cannot match plunger pumps, and limited oil and gas field conditions. Convenient assembly and post-maintenance, saving on-site work space, and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

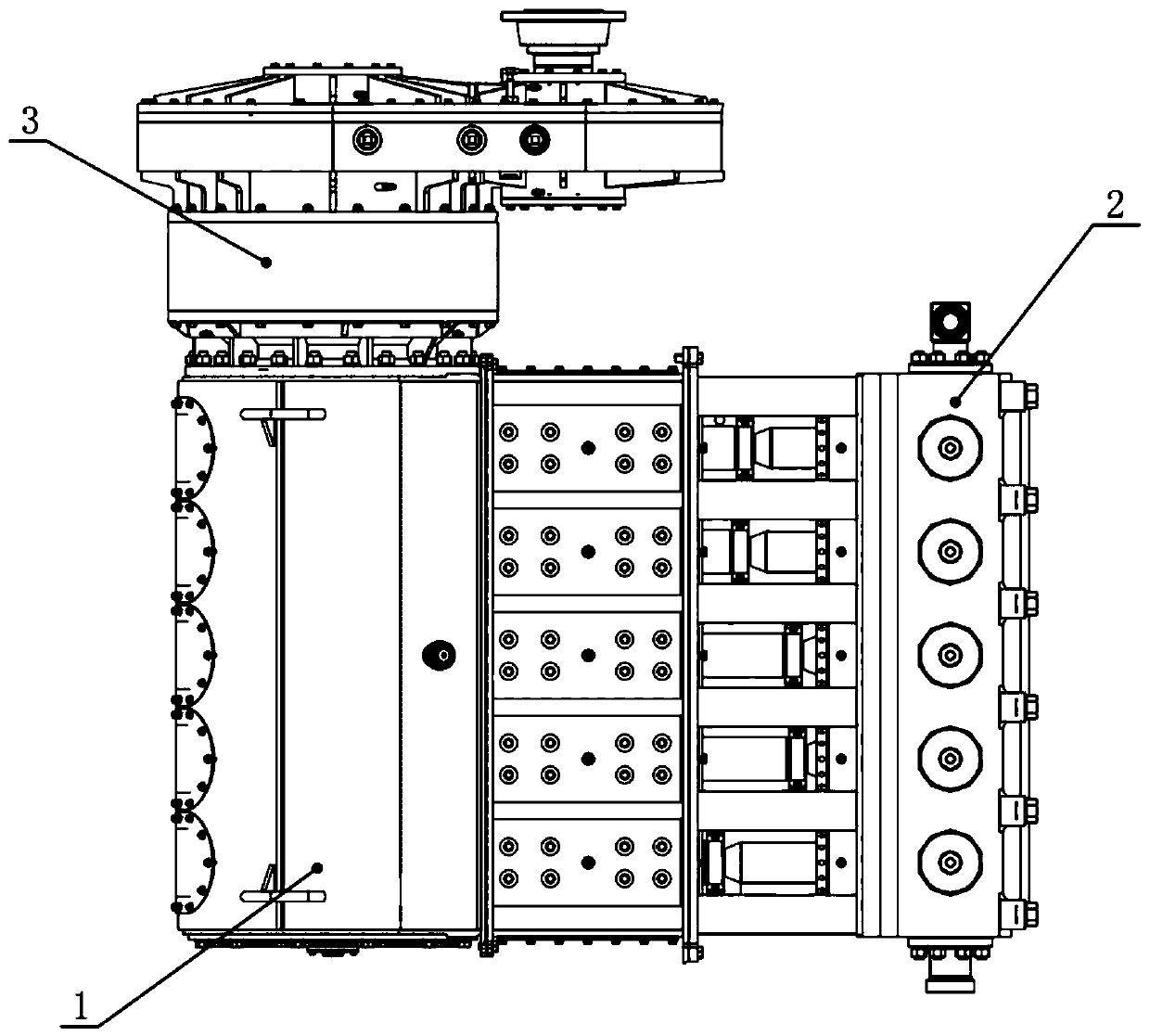

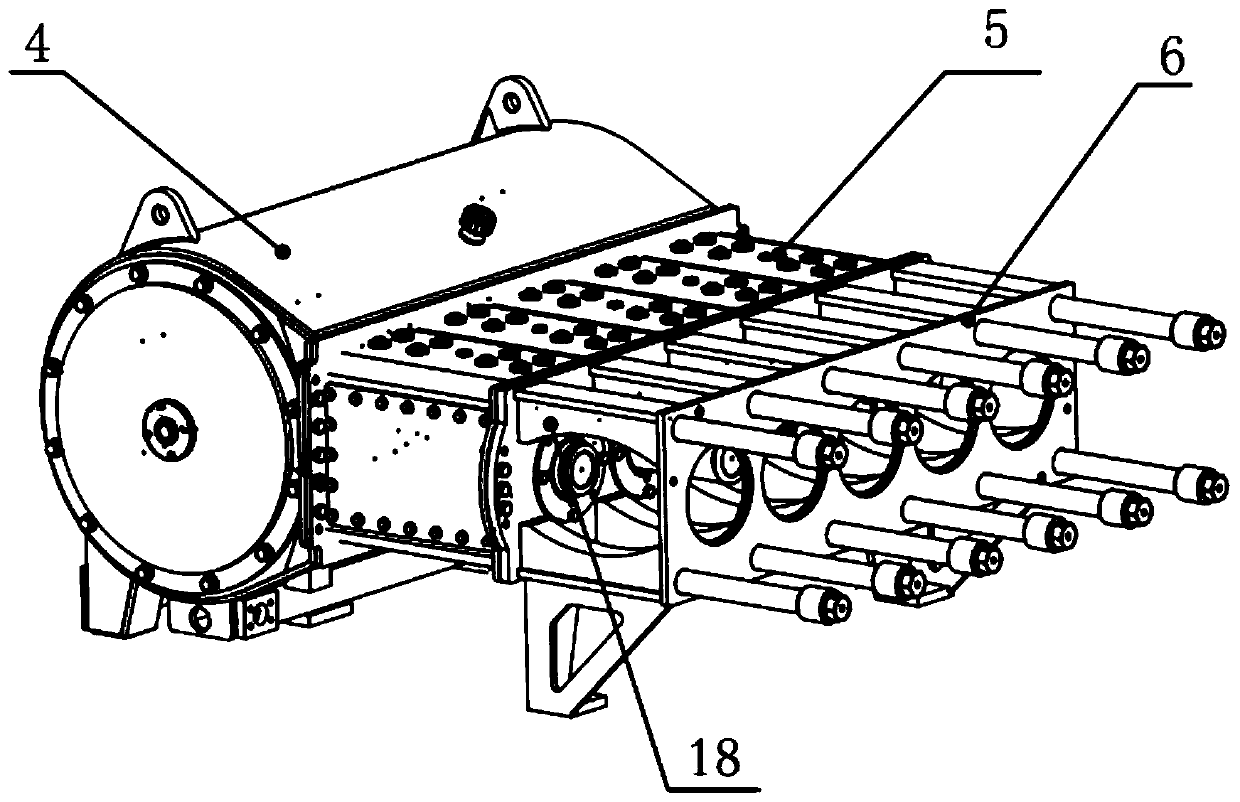

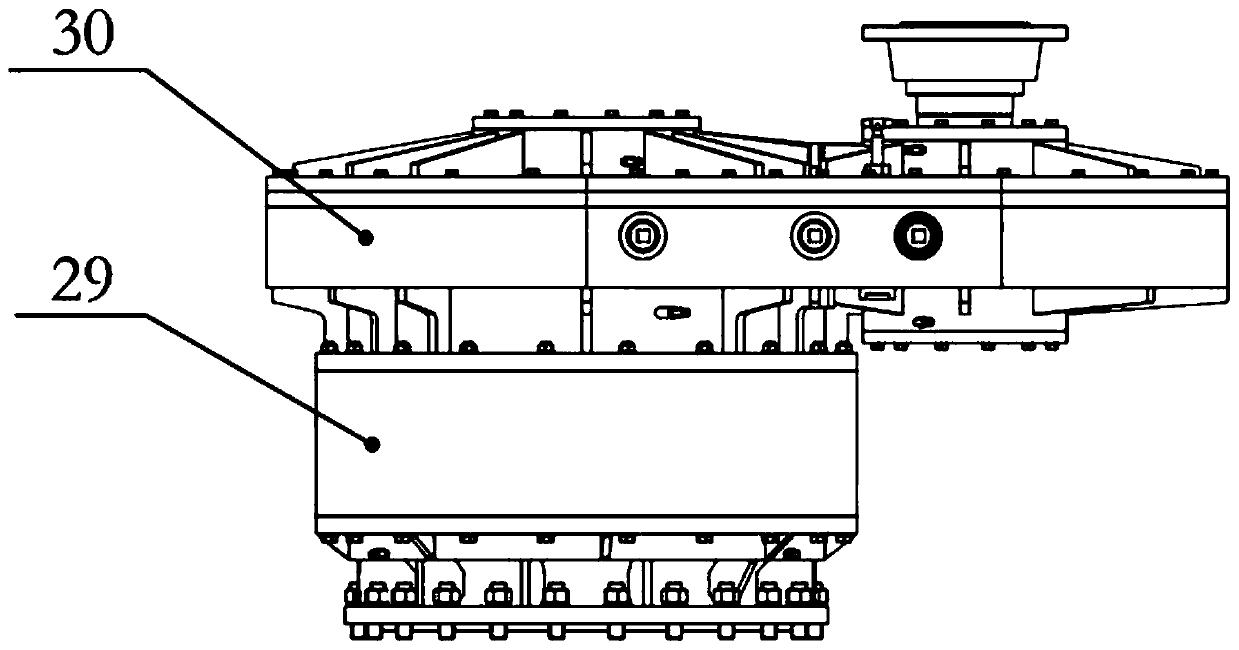

[0027] Examples such as Figures 1 to 9 As shown, a super-high-power five-cylinder plunger pump includes a power end assembly 1, a fluid end assembly 2, and a reduction box assembly 3. The power end assembly 1 adopts a segmented structure design, and the segmented The design makes the overall structure of the power end assembly 1 compact, the processing and manufacturing are easier, the assembly and later maintenance of the whole pump are also more convenient, and the processing cost is also reduced. The power end assembly 1 includes a crankcase 4, a crosshead casing 5 and a spacer 6, one end of the crosshead casing 5 is connected to the crankcase 4 through a hexagon head bolt, and the other end of the crosshead casing 5 One end is connected to the spacer 6 by bolts, the fluid end assembly 2 is set at one end of the spacer 6, and the bolts pass through the spacer 6 in turn, and the crosshead box 5 is connected to the crankcase 4, and the reduction box assembly 3 is connected b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com