Radiation heat dissipating coating and preparation method thereof

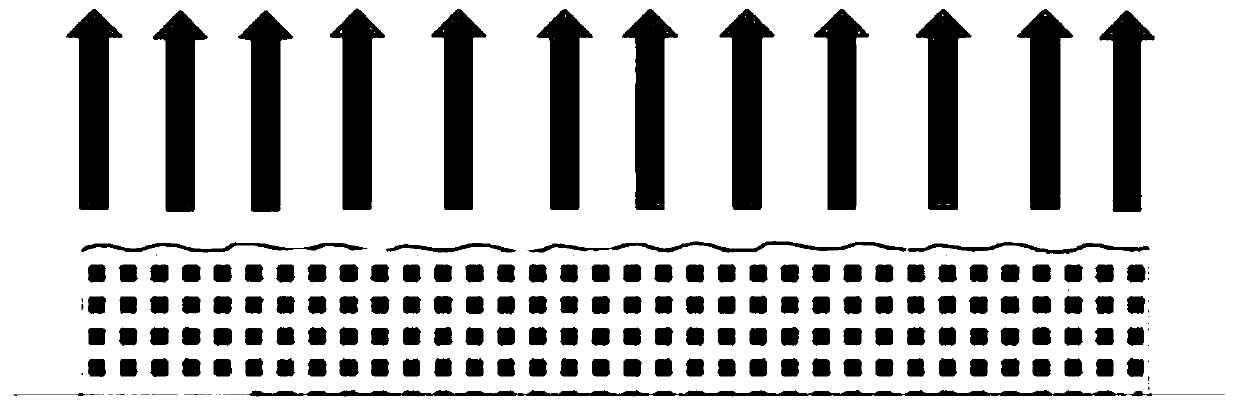

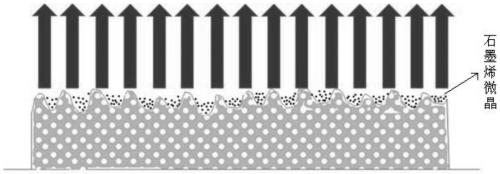

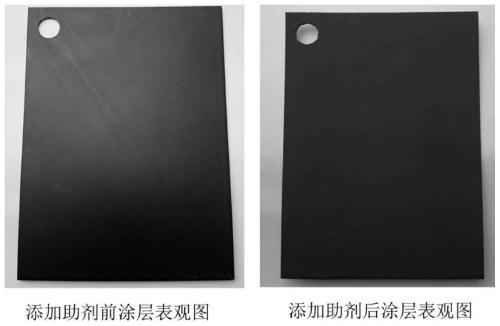

A radiation heat dissipation and coating technology, applied in the direction of epoxy resin coatings, coatings, etc., can solve the problems of low coating life, unsatisfactory heat dissipation effect, and low bonding strength, etc., to improve electrical conductivity, thermal conductivity, and radiation Effect of cooling surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A kind of radiation heat dissipation coating, its component distribution ratio is as follows by mass parts:

[0055] 50 parts of acetone, 60 parts of methyl ethyl ketone, 95 parts of cyclohexanone, 15 parts of graphene microcrystal, 100 parts of bisphenol A epoxy resin E-51, 1.6 parts of BYK-180, 1.6 parts of BYK-066N, D.E.H.52 9 Parts, XZ 92441.01 15 parts, white carbon black 5 parts.

[0056] Its preparation method comprises the following steps:

[0057] 1) Add the above-mentioned solvent (acetone, methyl ethyl ketone, cyclohexanone), graphene microcrystals and epoxy resin into the high-speed disperser, control the speed of the high-speed disperser to be 1600rpm, and stir for 1h to obtain a mixed solution;

[0058] 2) Add other components to the mixed solution in the above-mentioned high-speed disperser in turn, control the speed of the high-speed disperser to 3000 rpm, and stir for 1 hour to obtain a radiation heat-dissipating coating.

[0059] The same method as i...

Embodiment 2

[0061] A kind of radiation heat dissipation coating, its component distribution ratio is as follows by mass parts:

[0062] 45 parts of acetone, 60 parts of methyl ethyl ketone, 100 parts of cyclohexanone, 16 parts of graphene microcrystal, 120 parts of bisphenol A epoxy resin E-51, 1.5 parts of BYK-180, 1.5 parts of BYK-066N, D.E.H.52 8 Parts, XZ 92441.01 12 parts, white carbon black 6 parts.

[0063] Its preparation method comprises the following steps:

[0064] 1) Add the above-mentioned solvent (acetone, methyl ethyl ketone, cyclohexanone), graphene microcrystals and epoxy resin into the high-speed disperser, control the speed of the high-speed disperser to be 1600rpm, and stir for 1h to obtain a mixed solution;

[0065] 2) Add other components to the mixed solution in the above-mentioned high-speed disperser in turn, control the speed of the high-speed disperser to 3000 rpm, and stir for 1 hour to obtain a radiation heat-dissipating coating.

[0066] The same method as ...

Embodiment 3

[0068] A kind of radiation heat dissipation coating, its component distribution ratio is as follows by mass parts:

[0069] 45 parts of acetone, 60 parts of methyl ethyl ketone, 100 parts of cyclohexanone, 18 parts of graphene microcrystal, 115 parts of bisphenol A epoxy resin E-51, 1.5 parts of BYK-180, 1.5 parts of BYK-066N, D.E.H.52 8 parts, XZ 92441.01 10 parts, white carbon black 6 parts.

[0070] Its preparation method comprises the following steps:

[0071] 1) Add the above-mentioned solvent (acetone, methyl ethyl ketone, cyclohexanone), graphene microcrystals and epoxy resin into the high-speed disperser, control the speed of the high-speed disperser to be 1600rpm, and stir for 1h to obtain a mixed solution;

[0072] 2) Add other components to the mixed solution in the above-mentioned high-speed disperser in turn, control the speed of the high-speed disperser to 3000 rpm, and stir for 1 hour to obtain a radiation heat-dissipating coating.

[0073] The same method as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com