Preparation method of high purity graphite

A high-purity graphite and graphite technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., to achieve the effect of reducing purification temperature, improving production efficiency, and high application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

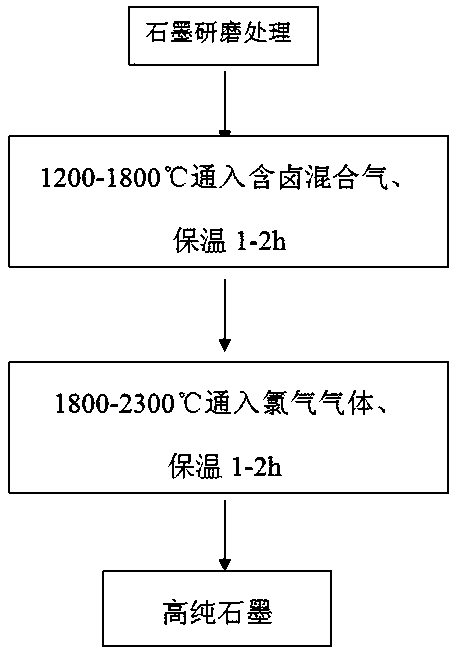

Image

Examples

specific Embodiment approach 1

[0013] Follow the steps below to prepare high-purity graphite:

[0014] Step 1: Take the graphite raw material that is ground to a particle size of 150-200 μm, and raise the temperature to 1200 °C under the protection of nitrogen gas at a heating rate of 15 °C / min; continue to heat up at 1200-1800 °C at a heating rate of 5 °C / min and simultaneously Introduce a halogen-containing mixed gas and keep it warm at 1680°C for 1 hour to obtain a solid product; the gas flow rate is 1.5m 3 / h;

[0015] Step 2: The obtained solid product continues to heat up in the graphite purification device and at the same time feed 99% chlorine gas to 2300°C, keep it warm for 2 hours, the heating rate is 2°C / min, and the gas flow rate is 2m 3 / h;

[0016] After testing, the carbon content of the graphite after the treatment in the first step is 99%, and the carbon content in the graphite after the treatment in the second step is 99.9999%.

specific Embodiment approach 2

[0017] Follow the steps below to prepare high-purity graphite:

[0018] Step 1: Take the graphite raw material that is ground to a particle size of 150-200 μm, and raise the temperature to 1200 °C under the protection of nitrogen gas at a heating rate of 15 °C / min; continue to heat up at 1200-1800 °C at a heating rate of 5 °C / min and simultaneously Introduce a halogen-containing mixed gas and keep it warm at 1680°C for 1 hour to obtain a solid product; the gas flow rate is 1.5m 3 / h;

[0019] Step 2: The obtained solid product continues to heat up in the graphite purification device and at the same time feed 99% chlorine gas to 2250°C, keep it warm for 2 hours, the temperature rise rate is 2°C / min, and the gas flow rate is 2m 3 / h;

[0020] After testing, the carbon content of the graphite after the treatment in the first step is 99%, and the carbon content in the graphite after the treatment in the second step is 99.999%.

specific Embodiment approach 3

[0021] Follow the steps below to prepare high-purity graphite:

[0022] Step 1: Take the graphite raw material that is ground to a particle size of 150-200 μm, and raise the temperature to 1200 °C under the protection of nitrogen gas at a heating rate of 15 °C / min; continue to heat up at 1200-1800 °C at a heating rate of 5 °C / min and simultaneously Introduce a halogen-containing mixed gas and keep warm at 1800°C for 1 hour to obtain a solid product; the gas flow rate is 1.5m 3 / h;

[0023] Step 2: The obtained solid product continues to heat up in the graphite purification device and at the same time feed 99% chlorine gas to 2100°C, keep it warm for 2 hours, the heating rate is 2°C / min, and the gas flow rate is 2m 3 / h;

[0024] After testing, the carbon content of the graphite after the treatment in the first step is 99%, and the carbon content in the graphite after the treatment in the second step is 99.99%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com