Elastic clamping overturning transporting mechanical arm

A technology of manipulator and clamping mechanism, which is applied in the direction of conveyor objects, transportation and packaging, etc. It can solve the problems of inability to turn over, easy to damage workpieces, and difficulty in adapting to the production rhythm of the assembly line, so as to improve the yield rate and product quality, and achieve precise clamping Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

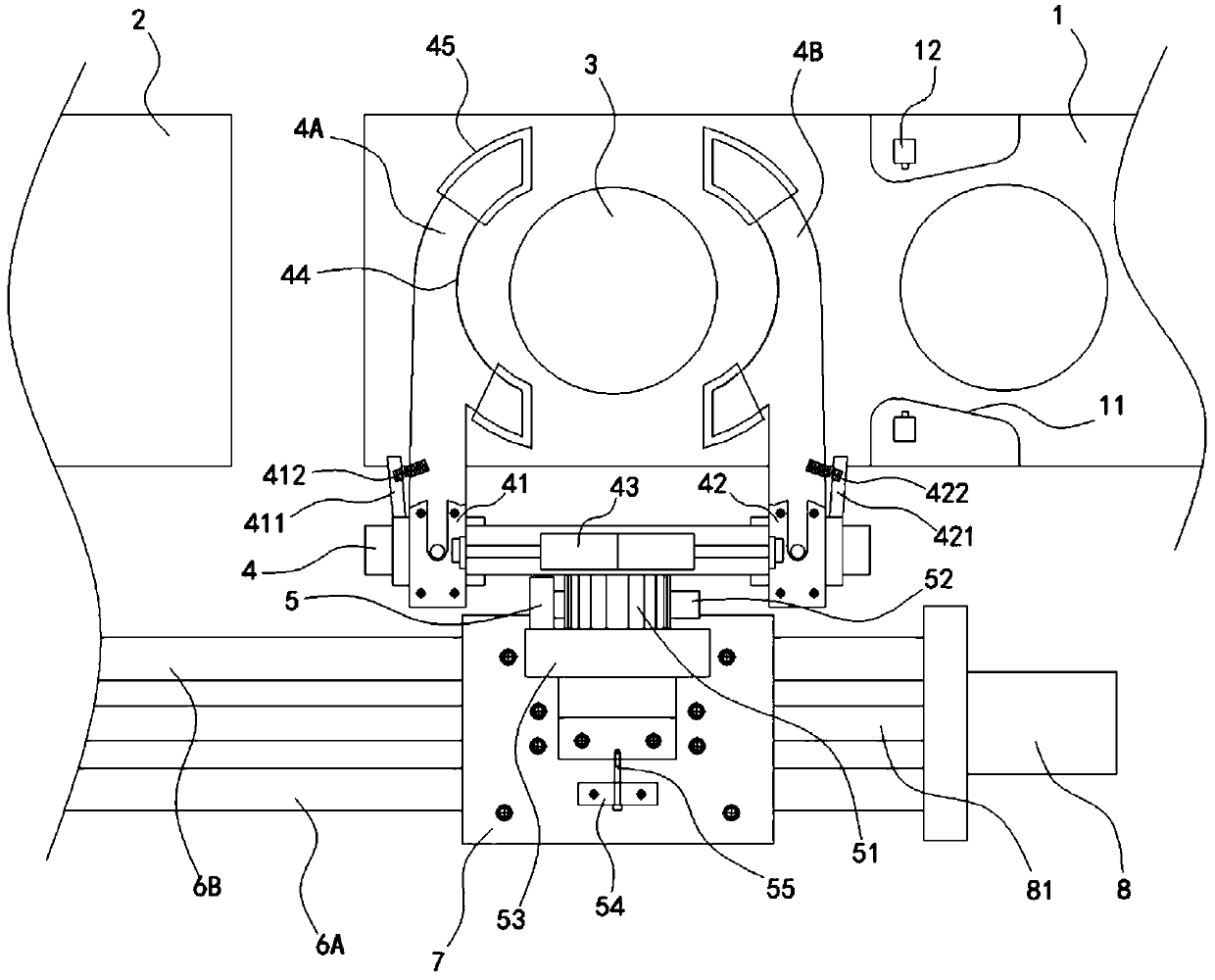

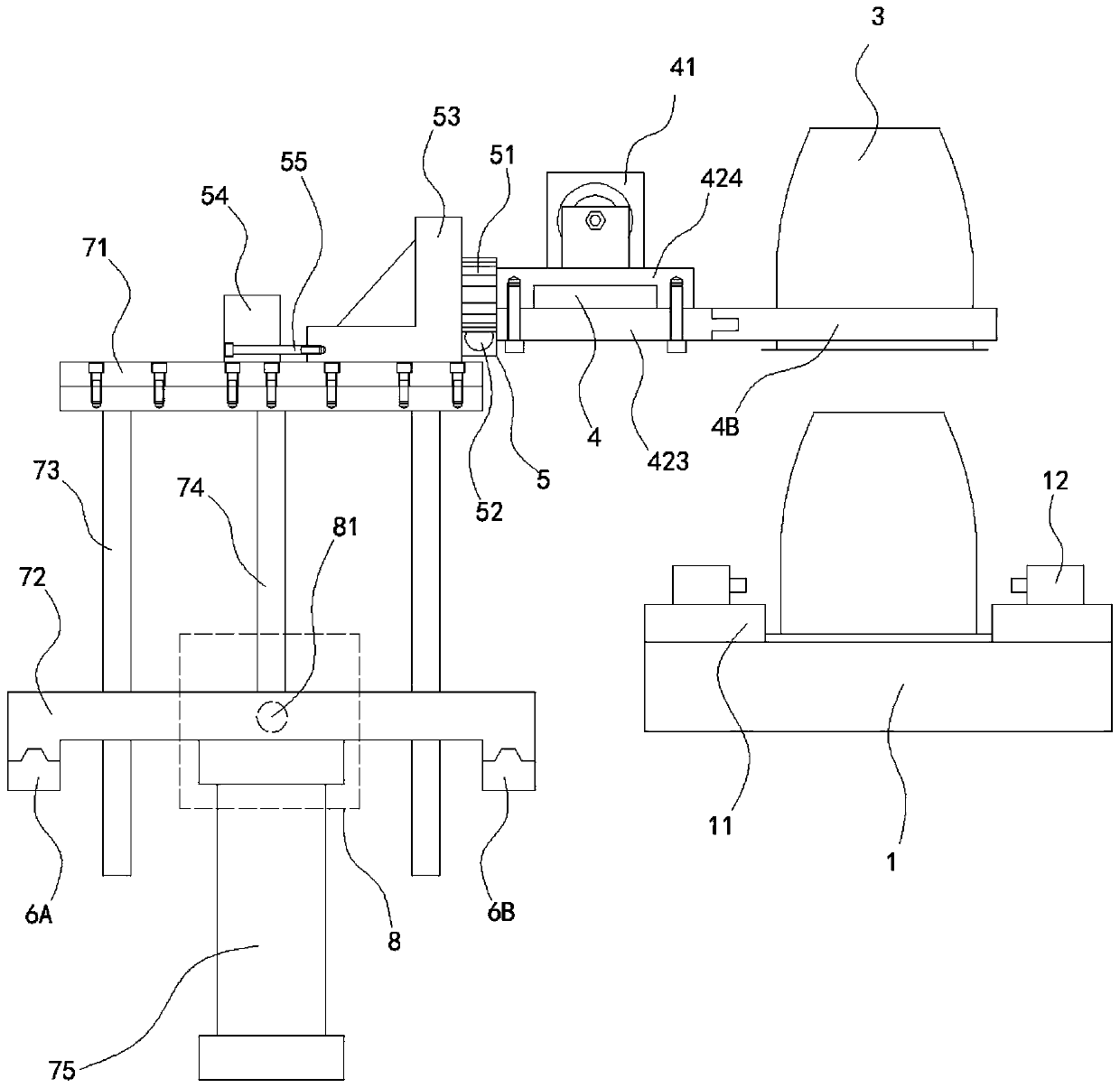

[0027] In order to make the purpose of the present invention, technical solutions and advantages clearer, the following will combine figure 1 - figure 2 The accompanying drawings describe the present invention in further detail.

[0028] refer to figure 1 - figure 2 As shown, an elastic clamping and turning transfer robot includes an elastic clamping mechanism for clamping a workpiece, a turning mechanism for turning over the elastic clamping mechanism, and a mounting table 7 .

[0029] The elastic clamping mechanism comprises the clamp arm slide rail 4 and the first and second clamp arms 4A, 4B. The first and second slide platforms 41, 42 are slidably arranged on the clamp arm slide rail 4, and the first and second slide platforms 41 , 42 are driven close or apart by the clamping drive device 43, and the clamping drive device 43 preferably adopts two cylinders, and the fixed end of the clamping drive device 43 is affixed on the clamp arm slide rail 4, and the expansion a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com