Automatic heat preservation building block production line

A self-insulating block and production line technology, which is applied in ceramic molding workshops, unloading devices, ceramic molding machines, etc., can solve the problem of difficult positioning of the mold lifting device, inaccurate positioning of the pressure head and the mold, and the occupation of the block curing room Large area and other problems, to achieve the effect of high equipment reliability, stable and reliable equipment operation, and stable lifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described below in conjunction with accompanying drawing by non-limiting embodiment:

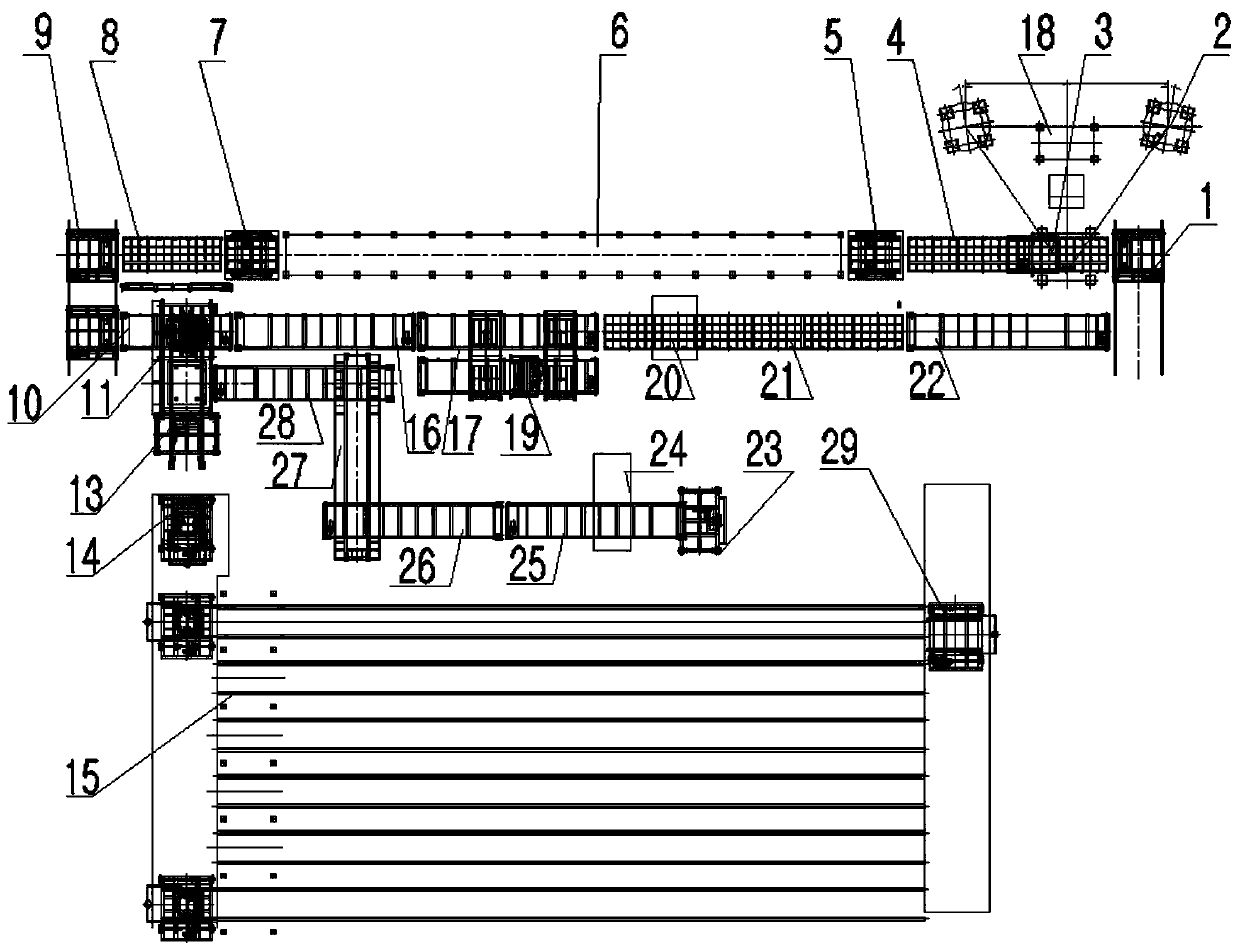

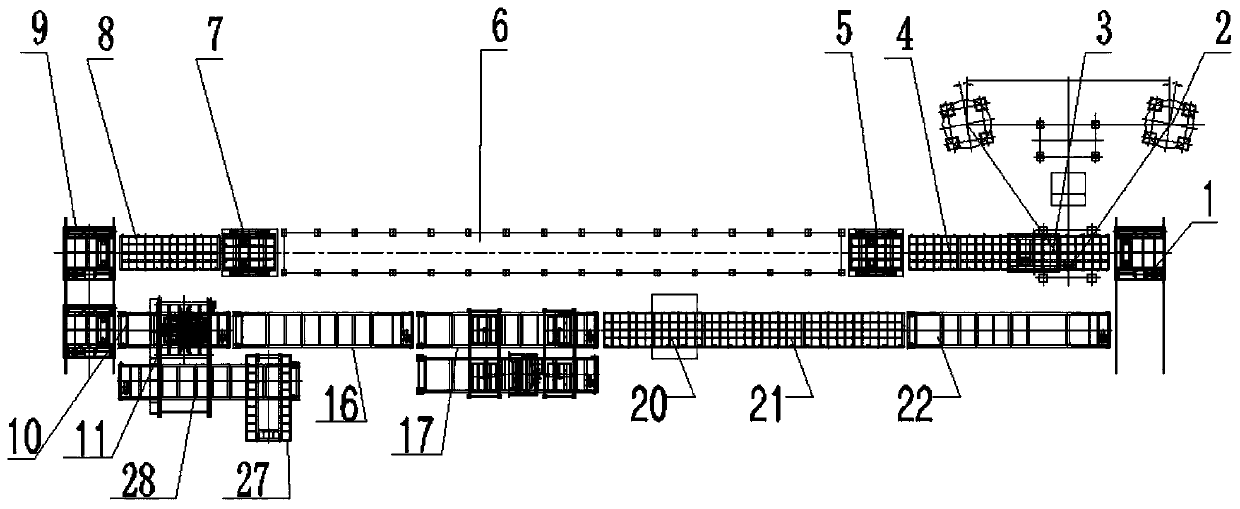

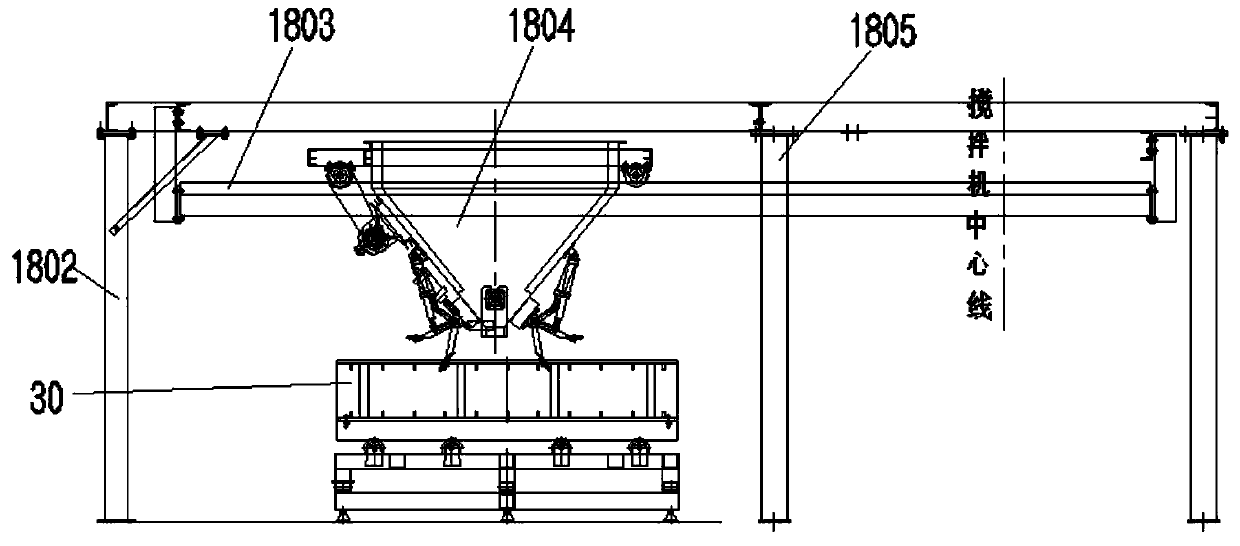

[0059] as attached figure 1 As shown, it is a fully automatic self-insulating block production line, which includes a mixer 2 for mixing materials, a distributor device 18 arranged below the mixer 2, and a 1# power transmission device is arranged below the distributor device 18 4. A vibrating device 3 is installed at the lower part of the 1# power conveying device 4, and a 1# hoist 5, a block curing room 6, and a 2# hoist 7 are sequentially arranged on the rear side of the 1# power conveying device 4 along the mold travel direction , 2# power conveying device 8, demoulding device 11, 1# roller chain conveyor 10 is arranged at the bottom of demoulding device 11, between the tail end of 2# power conveying device 8 and the head end of 1# roller chain conveyor 10 There is a 2# ferry car 9 between them, and a return track for returning to the 1# power...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com